Method for refining pressing flaxseed oil through solid adsorption and vacuum filtration

A technology of linseed oil and vacuum oil filtration, which is applied in the direction of fat oil/fat refining and fat production, which can solve the problems of unpleasant fragrance of linseed oil, damage to the internal quality of oil products, loss of linseed oil, etc., and reduce food safety Risk, improve quality grade, effect of removing bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

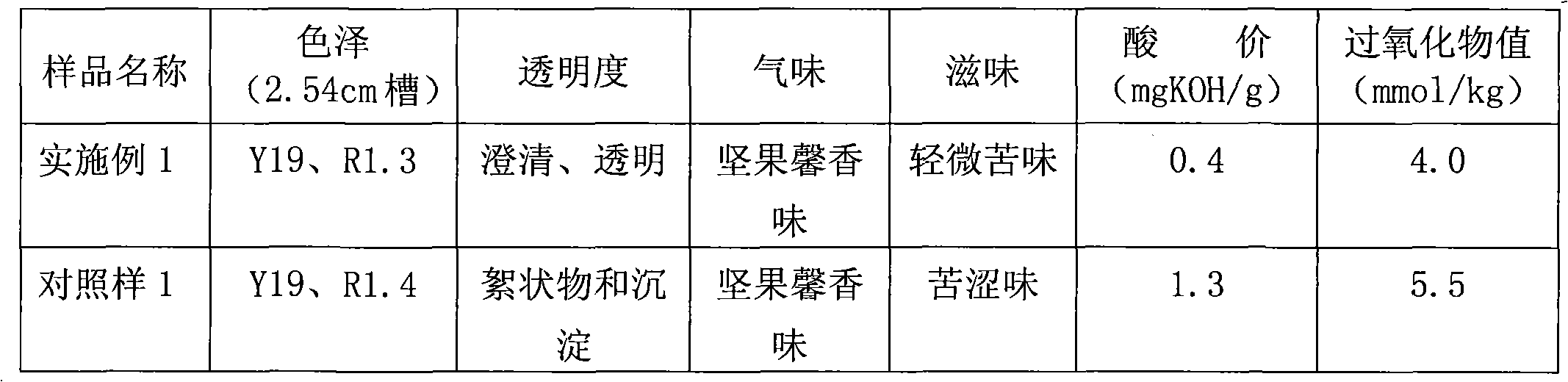

Embodiment 1

[0023] A method for solid adsorption and vacuum oil filtration refining pressed linseed oil, which comprises the following steps:

[0024] 1) Adsorption: Take the cold-pressed linseed oil squeezed out at room temperature at 35°C. The smell presents a nutty fragrance and no taste; the solid impurities are separated by centrifugation, the oil is cool and transparent, and the acid value is 1.3mgKOH / g oil. The peroxide value is 5.2mmol / kg, the color measured in a 2.54cm tank is Y19, R1.4, and the heat test at 280°C shows that the oil color becomes dark black with visible precipitates;

[0025] Take 100 parts by weight of the above-mentioned cold-pressed linseed oil and 2 parts by weight of diatomite adsorbent calcined by flux, and stir at a constant temperature of 45 ° C for 30 minutes (stirring contact);

[0026] The diatomite adsorbent calcined by flux is calcined by flux and diatomite according to the conventional calcination process, and the weight ratio of flux to diatomite i...

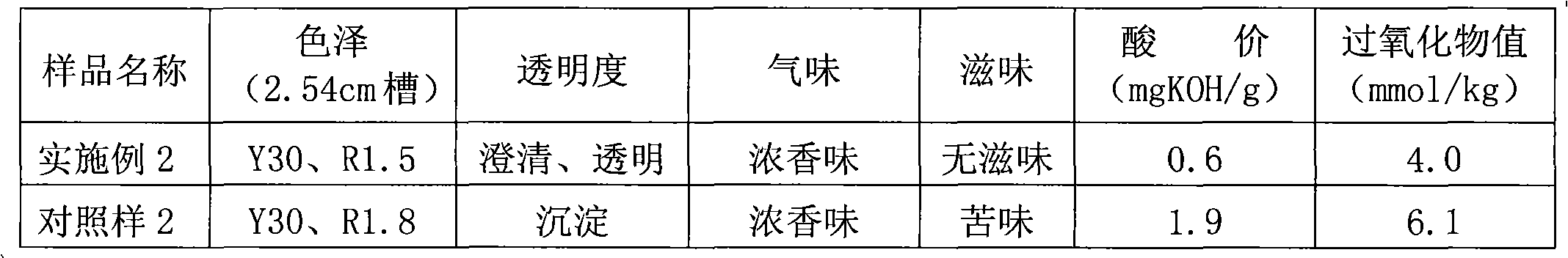

Embodiment 2

[0036] A method for solid adsorption and vacuum oil filtration refining pressed linseed oil, which comprises the following steps:

[0037] 1) Adsorption: The flaxseed roasted at 120°C is pressed by an oil press to produce oil. The hot-pressed flaxseed oil has a strong fragrance and no taste; the solid impurities are separated by centrifugation, and the oil is black. The acid value is 1.6mgKOH / g oil, the peroxide value is 6.0mmol / kg, the color measured by the 2.54cm tank is Y30, R1.9, and the heat test at 280°C, the color of the oil turns dark black with visible precipitates;

[0038] Take 100 parts by weight of the above-mentioned hot-pressed linseed oil and 2.5 parts by weight of diatomite adsorbent calcined by flux, and stir at a constant temperature of 45° C. for 30 minutes (stirring contact).

[0039] The diatomite adsorbent calcined by flux is calcined by flux and diatomite according to the conventional calcination process, and the weight ratio of flux to diatomite is 5:1...

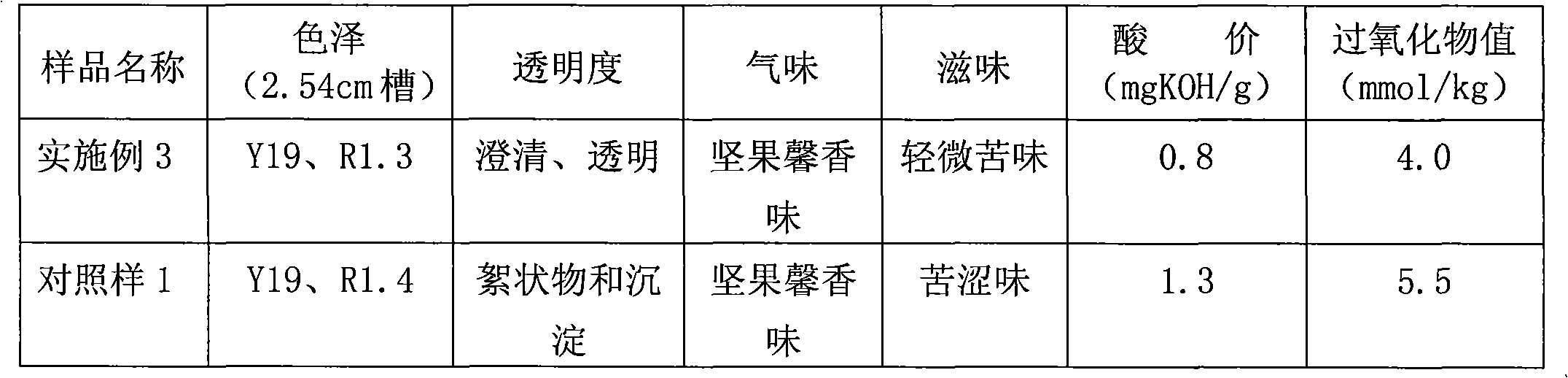

Embodiment 3

[0049] A method for solid adsorption and vacuum oil filtration refining pressed linseed oil, which comprises the following steps:

[0050] 1) Adsorption: 100 parts by weight of pressed linseed oil (cold-pressed linseed oil, the same as in Example 1) was contacted with 0.5 parts by weight of diatomite adsorbent calcined with flux at 30° C. for 30 minutes;

[0051] The described diatomite adsorbent calcined by flux is calcined by flux and diatomite according to the conventional calcination process (i.e. diatomite production), and the weight ratio of flux to diatomite is 8: 100; wherein , the flux is potassium hydroxide.

[0052] 2) Winterization: Cool to 5°C and freeze for 4 hours, then filter to remove solids;

[0053] 3) Vacuum oil filtration: At a temperature of 50°C, the linseed oil from which solids have been removed is passed through a vacuum oil filter filled with activated alumina / silicon oxide (an existing complete set of equipment) for vacuum oil filtration to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com