Corynebacterium glutamicum capable of producing succinic acid with high yield

A technology of Corynebacterium glutamicum and succinic acid, which is applied in the field of microorganisms, can solve the problems of affecting the quality of fermentation products and increasing the separation load, and achieves the effect of low cost, few by-products and single fermentation products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Plate medium: peptone 10g / L, yeast extract 5g / L, NaCl 10g / L, agar 20g / L, pH7.0.

[0034] Aerobic fermentation medium: glucose 20g / L, K 2 HPO 4 ·3H 2 O 1.5g / L, KH 2 PO 4 0.5g / L, MgSO 4 ·7H 2 O0.4g / L, FeSO 4 ·7H 2 O 20mg / L, MnSO 4 ·H 2 O 20mg / L, urea 2.5g / L, biotin 100μg / L, vitamin B1200μg / L, initial pH 7.0. 5L fermenter with 3L liquid, sterilized at 115°C for 10 minutes.

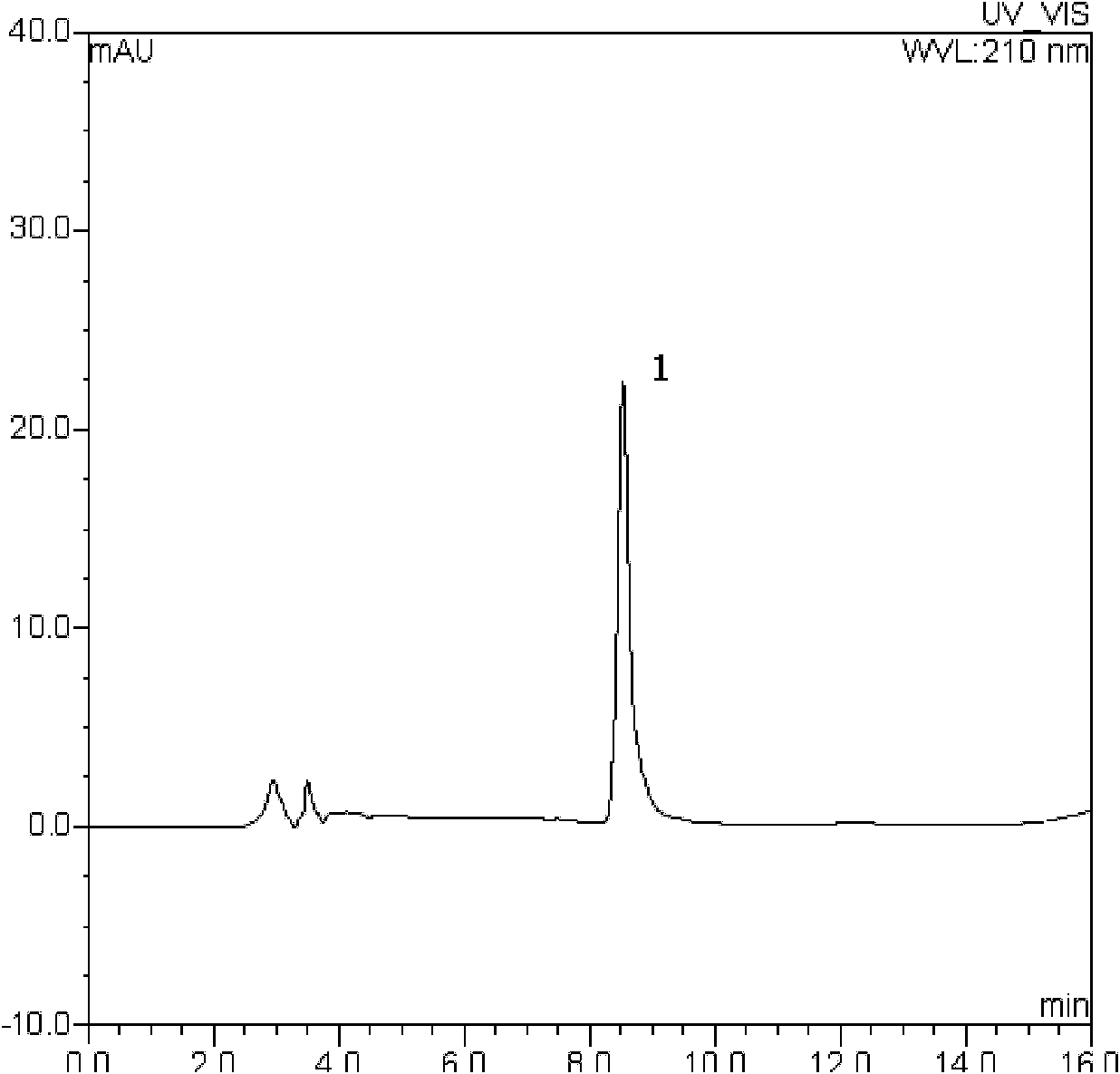

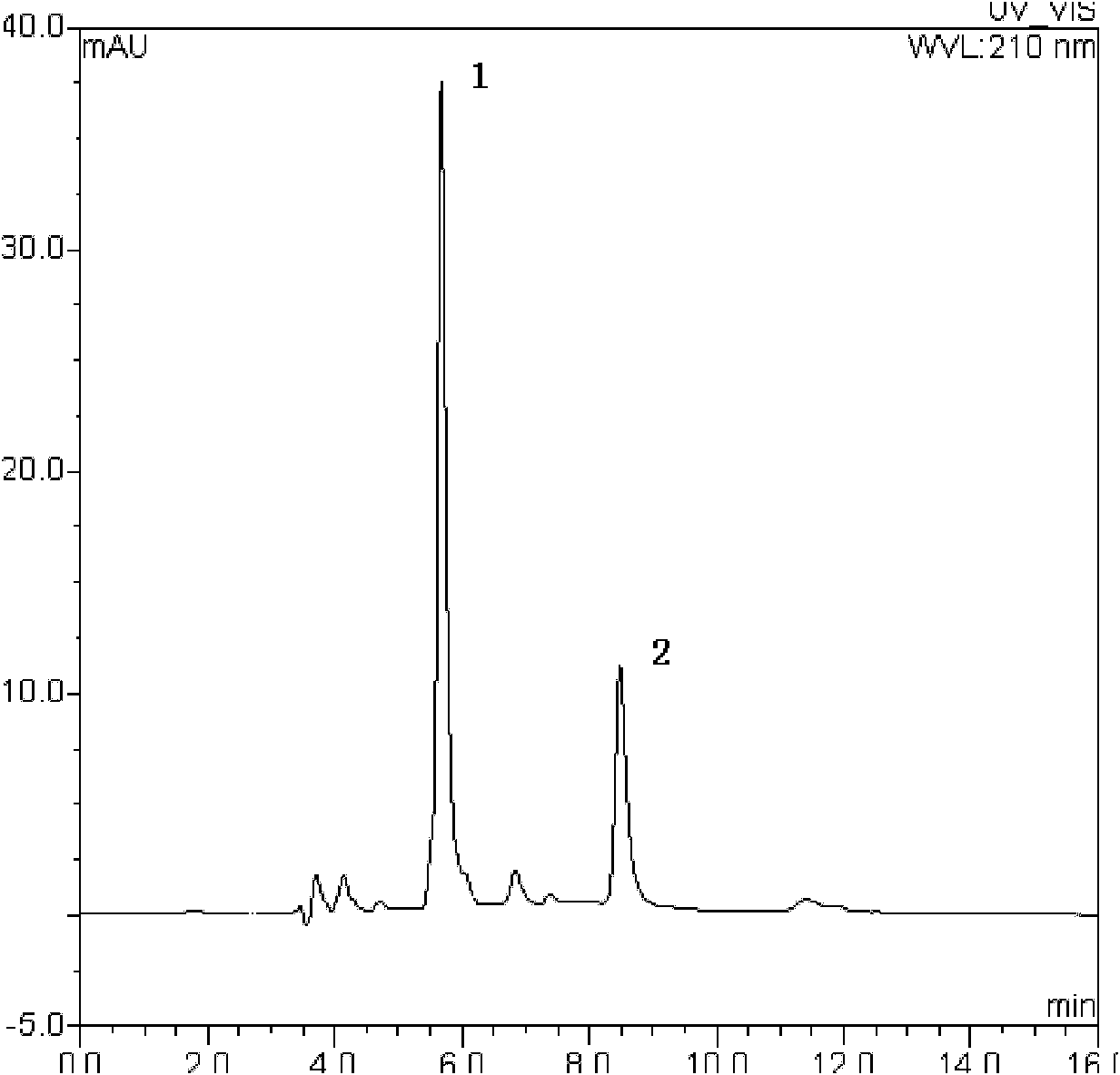

[0035] The bacteria with the preservation numbers ATCC13032 and CGMCC No.3991 were first activated on a 30°C plate, and after 24 hours, two rings of well-grown bacteria were put into 30mL fermentation medium, cultivated at 30°C and 200rpm for 12h, and then according to 3% (v / v) Transfer the inoculation amount into 3L fermentation medium, pass air 1v / vm, rotate at 500rpm, 30°C, after aerobic fermentation for 12h, transfer to anaerobic fermentation, pass CO 2 0.2v / vm, rotation speed 200rpm, culture at 30°C. Add 20g / L glucose at the beginning of anaerobic fermentation and 12h after fermen...

Embodiment 2

[0037] Plate culture medium: with embodiment 1.

[0038] Aerobic fermentation medium: corn mash liquid 400mL / L (the sugar content of corn mash liquid is about 50g / L), K 2 HPO 4 ·3H 2 O 1.5g / L, KH 2 PO 4 0.5g / L, MgSO 4 ·7H 2 O 0.4g / L, FeSO 4 ·7H 2 O 20mg / L, MnSO 4 ·H 2O 20mg / L, urea 2.5g / L, biotin 100μg / L, vitamin B1200μg / L, initial pH 7.0. 5L fermenter with 3L liquid, sterilized at 115°C for 10 minutes.

[0039] The preservation numbers are ATCC13032 and CGMCC No.3991 bacteria first activated strains on 30 ° C plate, 24 hours after two rings of well-grown bacteria into 30 mL fermentation medium, 30 ° C, 200 rpm culture for 12 h, and then according to 3% (v / v) Transfer the inoculation amount into 3L fermentation medium, pass air 1v / vm, rotate at 500rpm, 30°C, after aerobic fermentation for 14h, transfer to anaerobic fermentation, pass CO 2 0.2v / vm, rotation speed 200rpm, culture at 30°C. Add 20g / L glucose at the beginning of anaerobic fermentation and 12h after...

Embodiment 3

[0041] Plate culture medium: with embodiment 1

[0042] Aerobic fermentation medium: glucose 30g / L, peptone 5g / L, FeSO 4 ·7H 2 O 20mg / L, MnSO 4 ·H 2 O20mg / L, initial pH7.0. 5L fermenter tank liquid volume 3L, sterilized at 115°C for 10 minutes.

[0043] The bacteria with the preservation numbers ATCC13032 and CGMCC No.3991 were first activated on a 30°C plate, and after 24 hours, two rings of well-grown bacteria were put into 30mL fermentation medium, cultivated at 35°C and 200rpm for 12h, and then according to 3% (v / v) Transfer the inoculation amount into 3L fermentation medium, pass air 1v / vm, rotate at 500rpm, 30°C, after aerobic fermentation for 16h, transfer to anaerobic fermentation, pass CO 2 0.2v / vm, rotation speed 200rpm, culture at 35°C. Add 20g / L glucose at the beginning of anaerobic fermentation and 12h after fermentation respectively. After 36 hours of fermentation, the fermentation broth of CGMCC No. contained 35.1 g / L succinic acid. The conversion ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com