Mechanical pump type SCR urea spraying system

A technology of urea injection system and mechanical pump, which is applied in the direction of mechanical equipment, injection device, liquid injection device, etc. It can solve the problems of affecting the accuracy of injection metering, consuming electric energy of vehicles, and being unable to adjust, so as to avoid energy waste and reduce energy loss , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

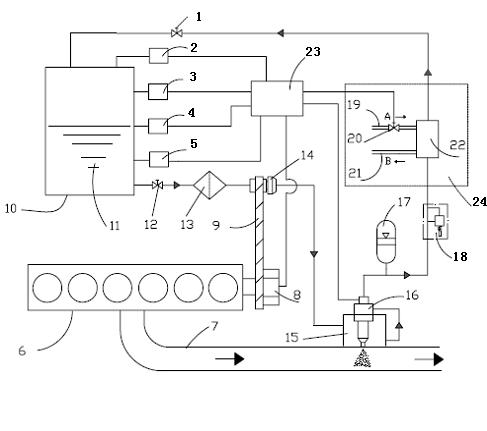

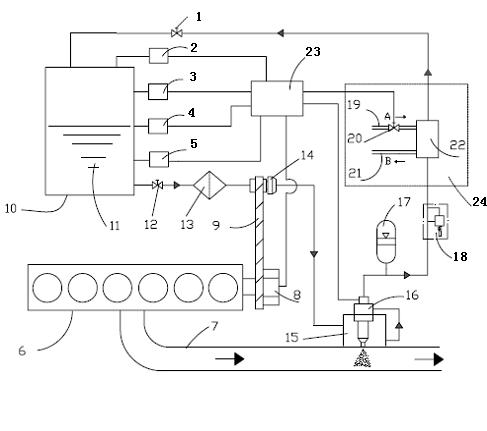

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: as figure 1 As shown, a mechanical pump SCR urea injection system consists of a urea tank 10, a urea tank switch valve 12, a filter 13, a urea pump 14, an accumulator 17, a urea nozzle 16, a heat exchanger 15, and a pressure regulating valve 18 , a cooling device 22, and an electronic control unit 23. Its characteristics are that the urea pump 14 is a mechanical pump, and the driving wheel 8 of the diesel engine drives the transmission shaft of the urea pump 14 through the pulley 9; the urea cooling device 24 is composed of a cooling device 22, a temperature control valve 20. The coolant inlet pipe 19 and the coolant outlet pipe 21 are composed. The urea cooling device 24 is arranged between the pressure regulating valve 18 and the switch valve 1 of the main pipeline. The accumulator 17 is placed at the outlet of the urea nozzle 16 and the pressure regulating va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com