Method for improving conductivity of indium-doped zinc oxide transparent conductive film

A transparent conductive film, conductive performance technology, applied to the conductive layer on the insulating carrier, ion implantation plating, coating, etc., can solve the problem of low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

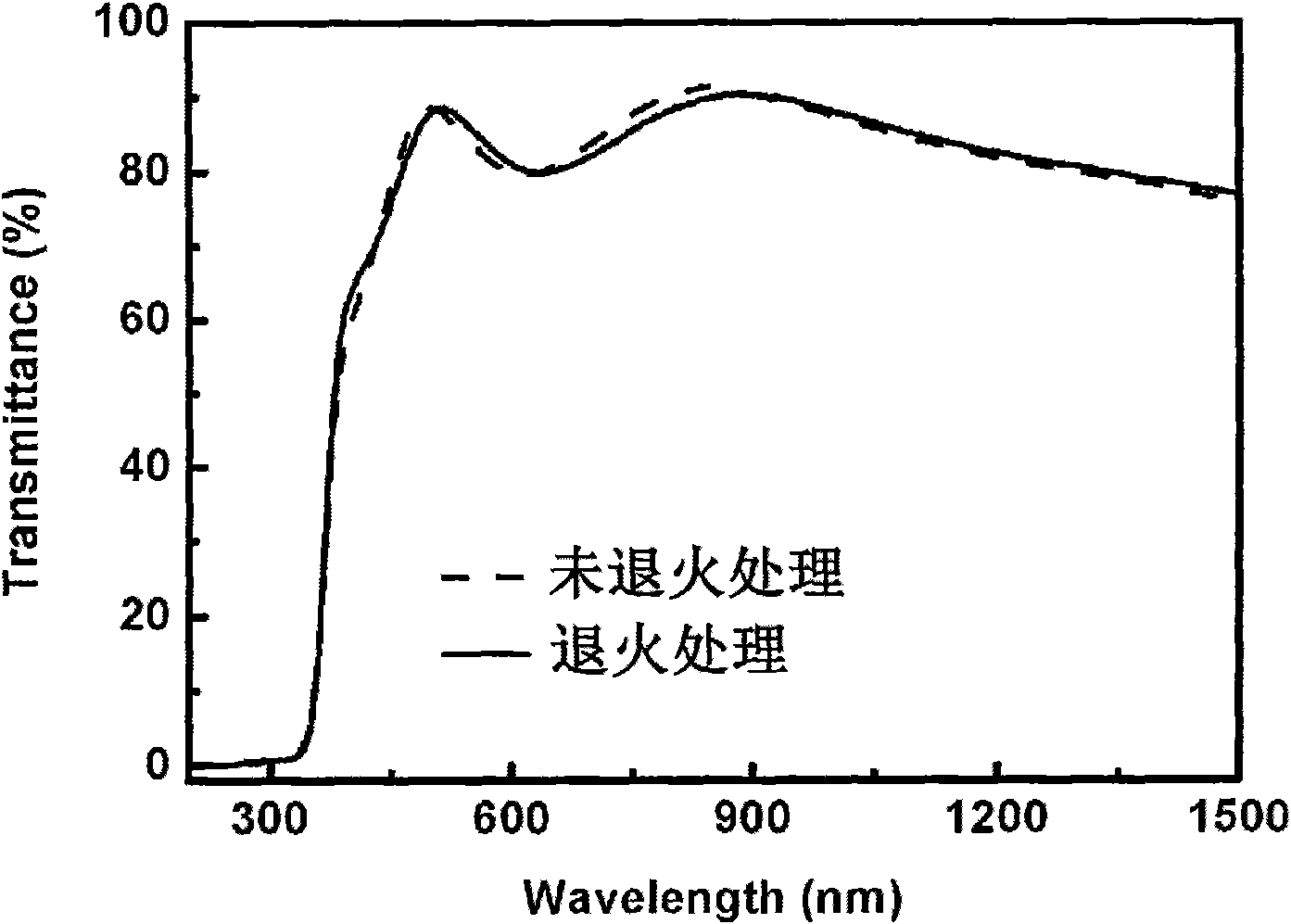

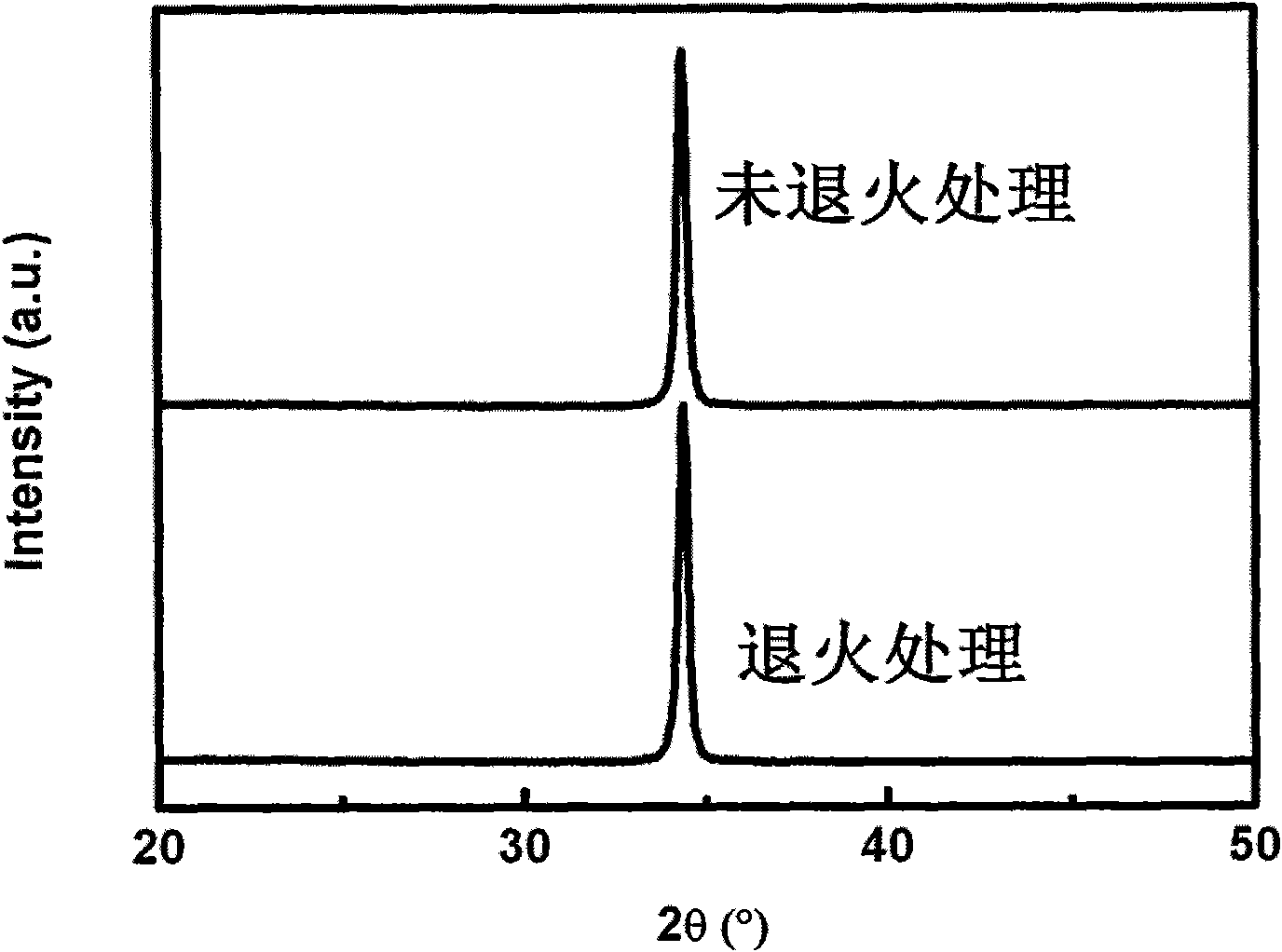

Embodiment 1

[0008] First, a zinc oxide ceramic target with a purity of 99.9% and an indium metal target are used to co-sputter and deposit an IZO transparent conductive film with a thickness of about 200nm by magnetron sputtering. is 0.5Pa, the background vacuum is 2×10 -4 Pa, the substrate temperature is 400°C, the RF sputtering power of ZnO target and Indium target is 10W / cm respectively 2 and 2W / cm 2 , the bias voltage is -100V, and the sample rotation speed is 6 rpm. Tests show that the atomic ratio of indium atoms to the sum of indium atoms and zinc atoms in the IZO transparent conductive film [In / (In+Zn)]≈3.5%, the indium content is very low, and its crystal structure is along the (002) orientation Hexagonal wurtzite phase structure, resistivity 1.3×10 -3 Ωcm, the carrier concentration is 1.1×10 21 / cm 3 , with a mobility of 4.53cm 2 V -1 S -1 , the transmittance is ~ 85% (400 ~ 1500nm).

[0009] Then put the prepared IZO transparent conductive film into the annealing furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| carrier concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com