Method for preparing novel tannic acid curing chitosan heavy metal ion adsorbent

A technology of heavy metal ions and chitosan, applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, to achieve the effects of reducing sewage treatment costs, easy desorption, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

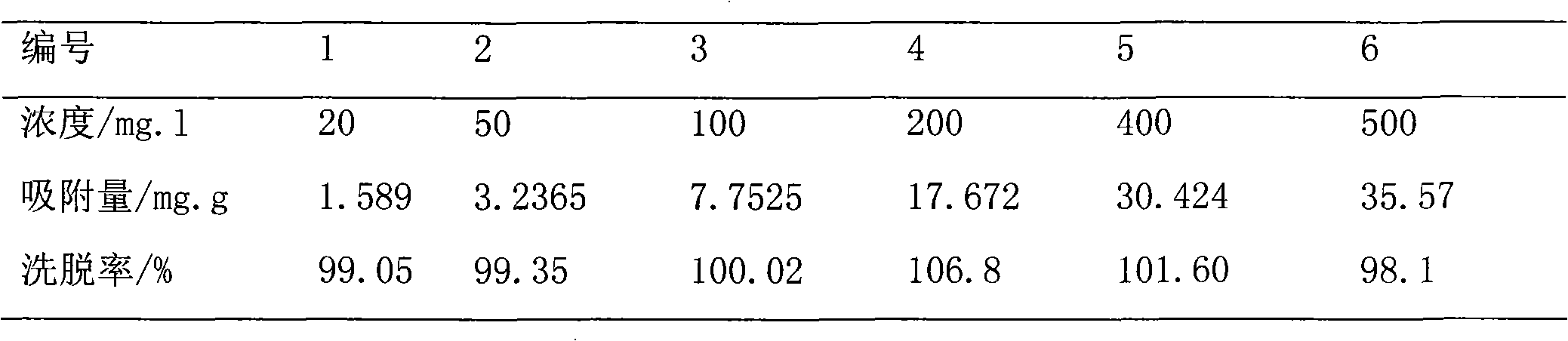

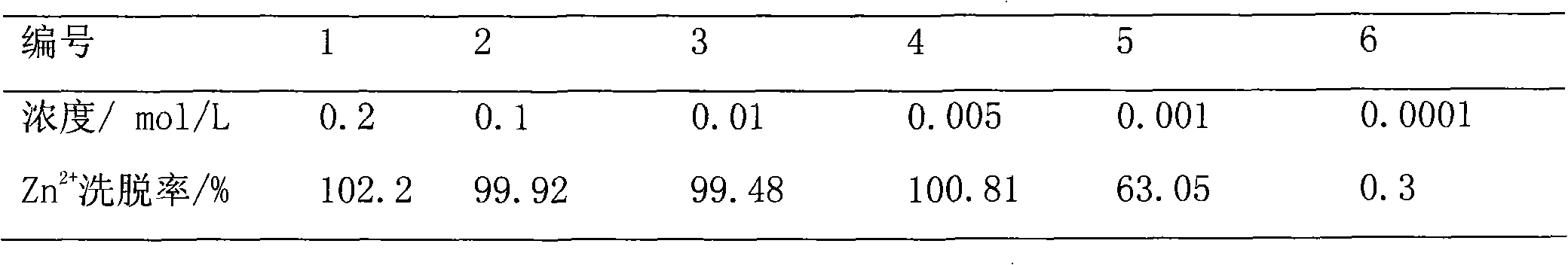

Examples

Embodiment 1

[0012] The preparation method of chitosan solidified tannic acid heavy metal ion adsorbent comprises the following two steps: the preparation of novel chitosan solidified tannic acid polysaccharide particles

[0013] Weigh 1.449 g of chitosan and dissolve it in 150 ml of water, add 0.648 g of acrylic acid and stir until completely dissolved, transfer it to a 250 ml four-neck bottle, under the protection of an oil bath and nitrogen, add 0.081 g of potassium persulfate at 70 ° C, stir to make the reaction When turbidity appears in about 1 hour, stop the reaction immediately and cool down rapidly, transfer it to a suction filter bottle, and filter it under a vacuum of 0.1 MPa, centrifuge the filtrate on a high-speed centrifuge at 12000r / min for 30 minutes, and wash the precipitate with distilled water until it is neutral, that is, Chitosan particles are available. Weigh 5 g of tannic acid in 100 mL of distilled water, adjust pH=7, filter to make it a clear solution, add chitosan ...

Embodiment 2

[0015] Preparation of novel chitosan solidified tannic acid polysaccharide particles

[0016] Weigh 1.449 g of chitosan and dissolve it in 150 ml of water, add 0.648 g of acrylic acid and stir until it is completely dissolved, transfer it to a 250 ml four-neck bottle, add 0.081 g of azoisopropylcyanide at 70 °C under the protection of an oil bath and nitrogen, and stir Make the reaction turbid for about 1 hour, stop the reaction immediately and cool it down quickly, transfer it to a suction filter bottle, filter it under a vacuum of 0.1 MPa, centrifuge the filtrate on a high-speed centrifuge at 12000r / min for 30 minutes, and wash the precipitate with distilled water until neutral , to obtain chitosan particles. Weigh 5 g of tannic acid in 100 mL of distilled water, adjust pH=7, filter to make it a clear solution, add chitosan particles, stir and react at 30° C. for 6 h, filter with suction and rinse with distilled water until neutral. Transfer the product to 300 mL of epichlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com