Method for preparing mesoporous carbon materials

A mesoporous carbon and mesoporous technology, applied in the field of preparation of mesoporous carbon materials, can solve the problems of unfavorable hydrophobicity and high production cost, achieve good strength, reduce processing cost, and stabilize the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

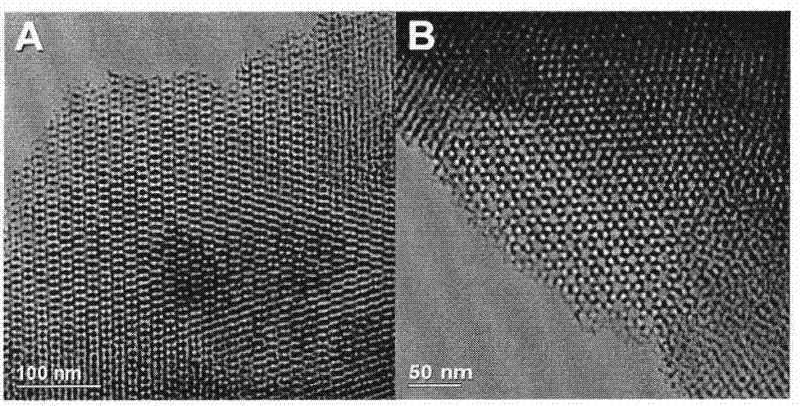

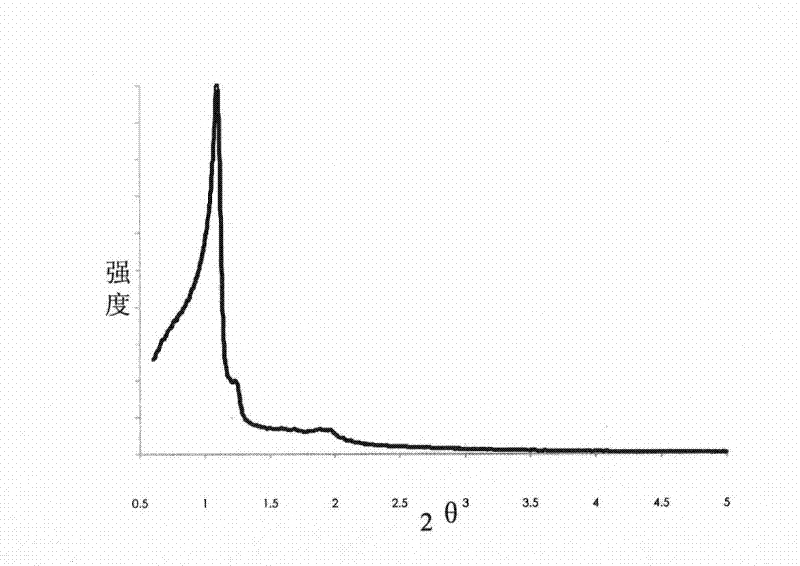

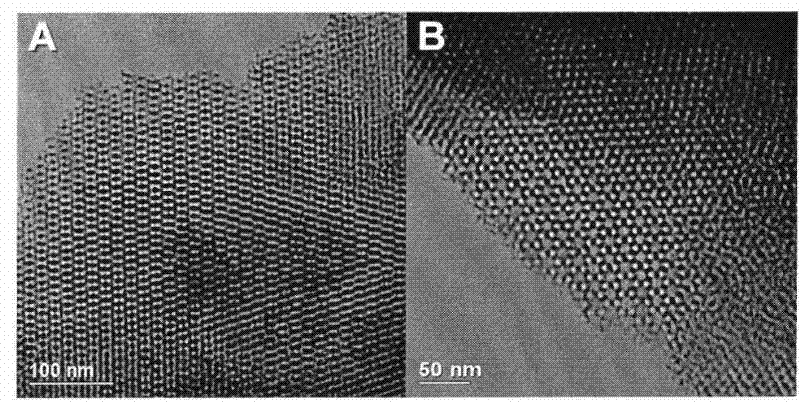

Image

Examples

Embodiment 1

[0018] 5.0 g of the synthesized mesoporous polymer material was placed in a muffle furnace, heated from room temperature to 400° C. for 3 hours in an air atmosphere, and kept at 400° C. for 3 hours to obtain a mesoporous carbon material (carrier I).

[0019] Catalyst preparation: Dissolve 0.2g of cesium hydroxide and 0.03g of boric acid in 20mL of water and divide it into two parts, add 10mL of one part to 1.0g of mesoporous carbon material (FDU-14), stir for 6 hours and place it in 80 ℃ oven for 24 hours, put the taken out solid material into another 10mL solution, stir for 6 hours and place it in an 80℃ oven for 24 hours, take it out and raise the temperature from room temperature to 400℃ for 3 hours in nitrogen atmosphere, The temperature was kept at 400° C. for 3 hours to obtain a catalyst material (catalyst I).

[0020] With catalyst I as reaction catalyst, raw material toluene and methyl alcohol are with molar ratio 5: 1, with the speed of 2.0 milliliters / hour and the ni...

Embodiment 2~4

[0022] According to the various steps and conditions of Example 1, the carrier and catalyst were prepared and the catalyst was evaluated, except that the calcination temperature of the carrier was changed. The calcination conditions and evaluation results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com