System and method for processing alkaline residue wastewater by utilizing supercritical water oxidation method

A technology for supercritical water oxidation and alkali slag wastewater, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of high cost and complex structure of wastewater treatment system, and achieve the effect of reducing cost and simple treatment system and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

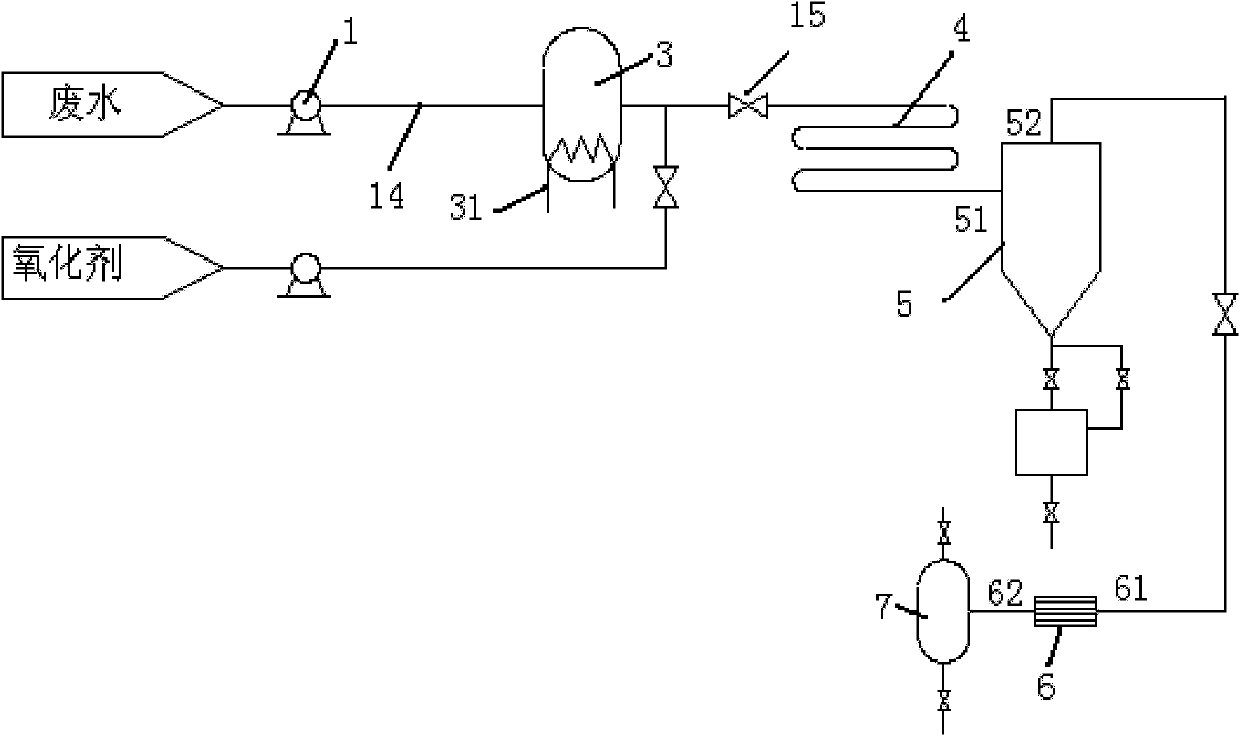

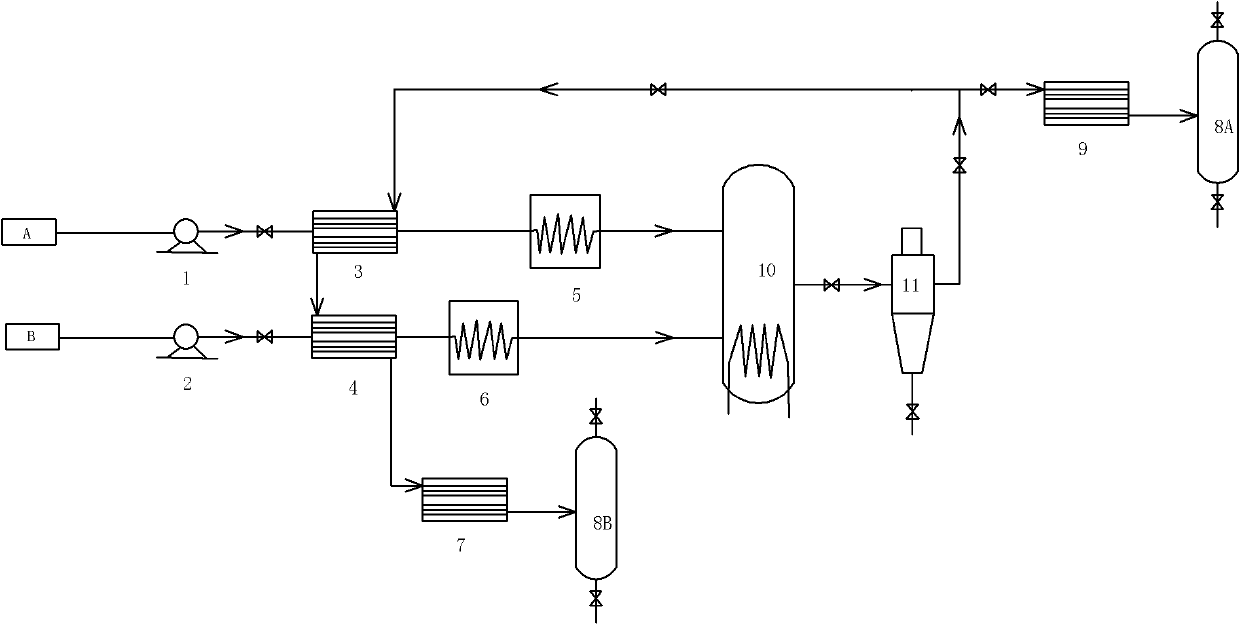

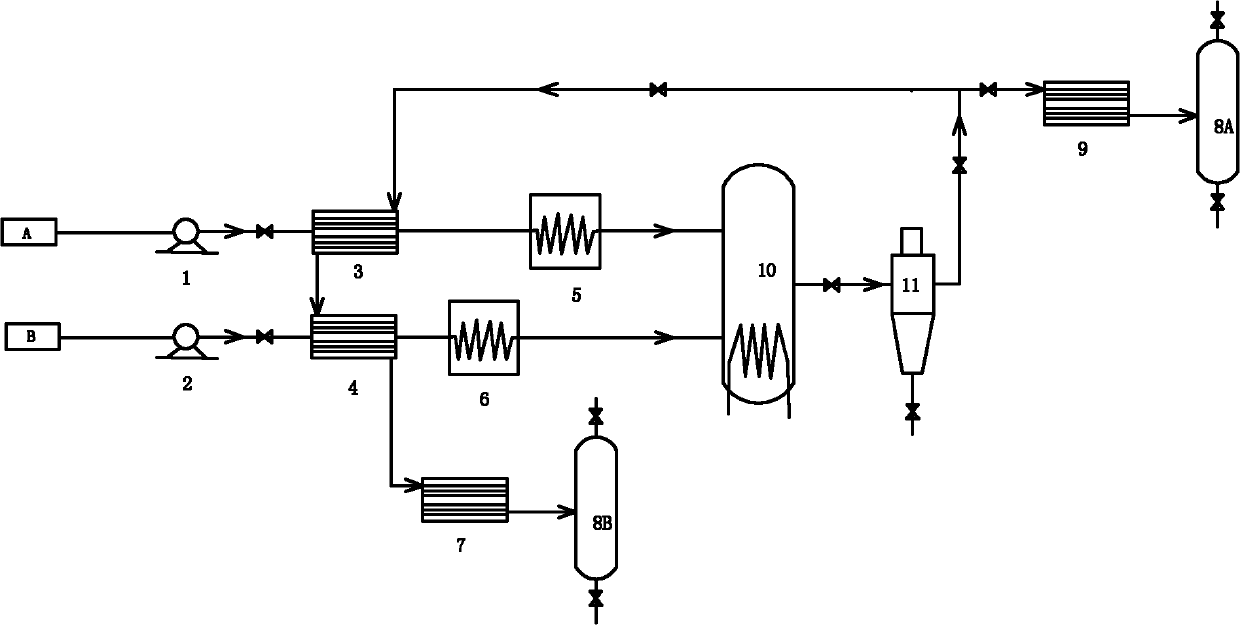

[0033] like figure 1 As shown, the system for treating alkali slag wastewater by supercritical water oxidation method includes a high-pressure wastewater plunger pump 1, an oxidant pump 2, a wastewater heat exchanger 3, an oxidant heat exchanger 4, a wastewater preheater 5, and an oxidant preheater 6 , a first condenser 7, gas-liquid separators 8A and 8B, a second condenser 9, a supercritical reactor 10, a high-pressure hydrocyclone 11, a waste water storage tank A, and an oxidant storage tank B.

[0034] A method for treating alkali slag wastewater by supercritical water partial oxidation, comprising the following steps:

[0035] (1) Use the high-pressure waste water plunger pump 1 to inject the alkali slag waste water into the supercritical reactor 10 through the waste water heat exchanger 3 and the waste water preheater 5;

[0036] (2) After part of the alkaline slag wastewater enters the supercritical reactor 10, close the high-pressure wastewater plunger pump 1 and the o...

Embodiment 2

[0045] Such as figure 1 As shown, the difference between this example and Example 1 is that the oxidant participating in the reaction is liquid oxygen, comprising the following steps:

[0046] (1) Use the high-pressure waste water plunger pump 1 to inject the alkali slag waste water into the supercritical reactor 10 through the waste water heat exchanger 3 and the waste water preheater 5;

[0047] (2) After part of the alkaline slag wastewater enters the supercritical reactor 10, close the high-pressure wastewater plunger pump 1 and the outlet valve of the supercritical reactor 10, start the heater 10 in the supercritical reactor, and inject the alkaline slag into it The waste water is statically heated to 400~600 ℃;

[0048] (3) Start the waste water preheater 5 and the oxidant preheater 6, and set the preheating temperature at 300~350°C;

[0049] (4) Start the high-pressure waste water plunger pump 1, and continue to inject alkali slag waste water into the supercritical re...

Embodiment 3

[0056] Such as figure 1 Shown, what this example differs from Example 1 is that the oxidizing agent participating in the reaction is a potassium permanganate solution, comprising the following steps:

[0057] (1) Use the high-pressure waste water plunger pump 1 to inject the alkali slag waste water into the supercritical reactor 10 through the waste water heat exchanger 3 and the waste water preheater 5;

[0058] (2) After part of the alkaline slag wastewater enters the supercritical reactor 10, close the high-pressure wastewater plunger pump 1 and the outlet valve of the supercritical reactor 10, start the heater 10 in the supercritical reactor, and inject the alkaline slag into it The waste water is statically heated to 400~600 ℃;

[0059] (3) Start the waste water preheater 5 and the oxidant preheater 6, and set the preheating temperature at 300~350°C;

[0060] (4) Start the high-pressure waste water plunger pump 1, and continue to inject alkali slag waste water into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com