Method for extracting myrosinase

An extraction method, sulfatase technology, applied in the field of agriculture, can solve the problem that the separation and purification method of myrosinase has not been studied and explained in detail, and achieve broad research value and market prospects, rich sources of raw materials, extraction method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

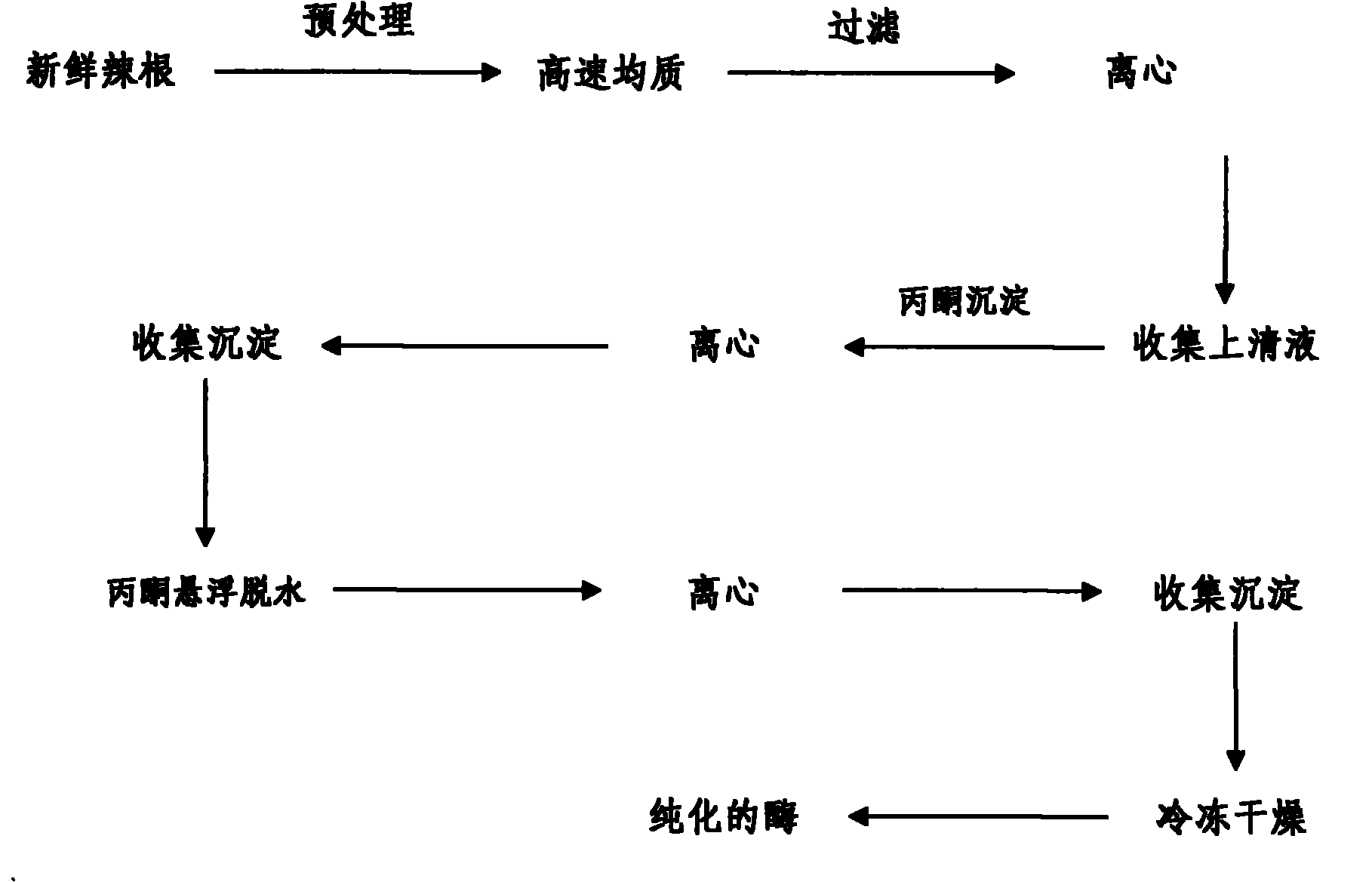

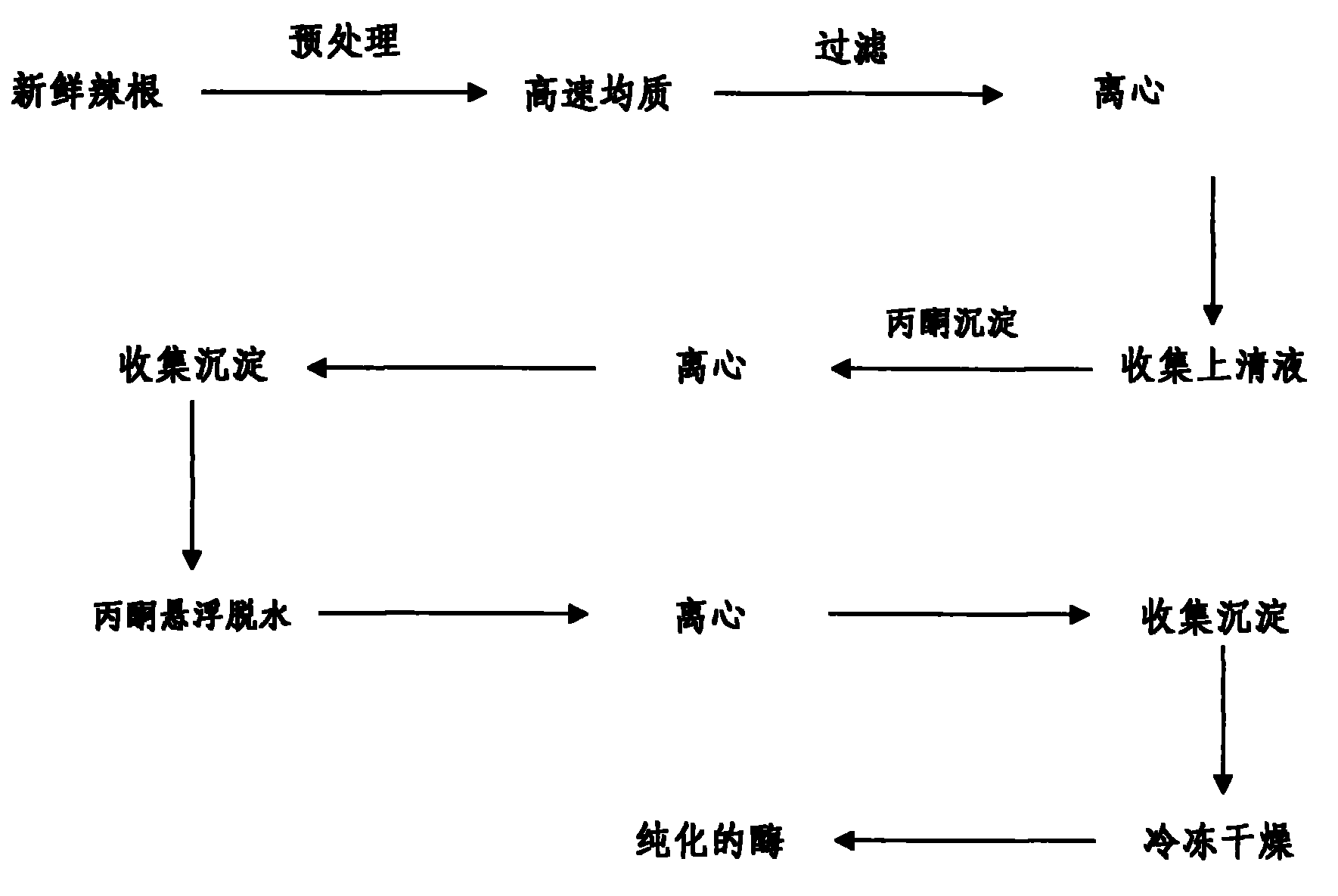

Method used

Image

Examples

Embodiment approach 1

[0031] (1) By weight percentage, take 2 parts of frozen horseradish slices, add 4 parts of impurity-free deionized water (4 ℃ refrigerator precooling), the pH value of distilled water is adjusted between 6 ± 0.5, and then quickly ( within 2 minutes) into a homogenized pulp, put the whole pulp into the press, squeeze out all the juice with power hydraulic pressure, filter with 3 to 5 layers of medical gauze, and collect the filtrate; use qualitative analysis filter paper (medium speed) Carry out vacuum filtration on the filtrate, (vacuum degree -0.1~-0.01Mpa) and then collect the filtrate, enter the next processing step. The whole process requires to be carried out at low temperature (3-5°C).

[0032] (2) The collected filtrate was placed at 3-5° C. for 2 h, and the supernatant was subjected to cryogenic centrifugation (4° C., 6000 r / min, 15 min), and the precipitate was discarded. The supernatant was taken and refrigerated at 3-5°C until separation and purification.

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com