Low-cost high-performance AB5 type hydrogen storage alloy and preparation method thereof

A hydrogen storage alloy and alloy technology, which is applied in the direction of alkaline battery electrodes, process efficiency improvement, electrical components, etc., can solve the problems of high price, achieve high capacity, long life, and good recycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

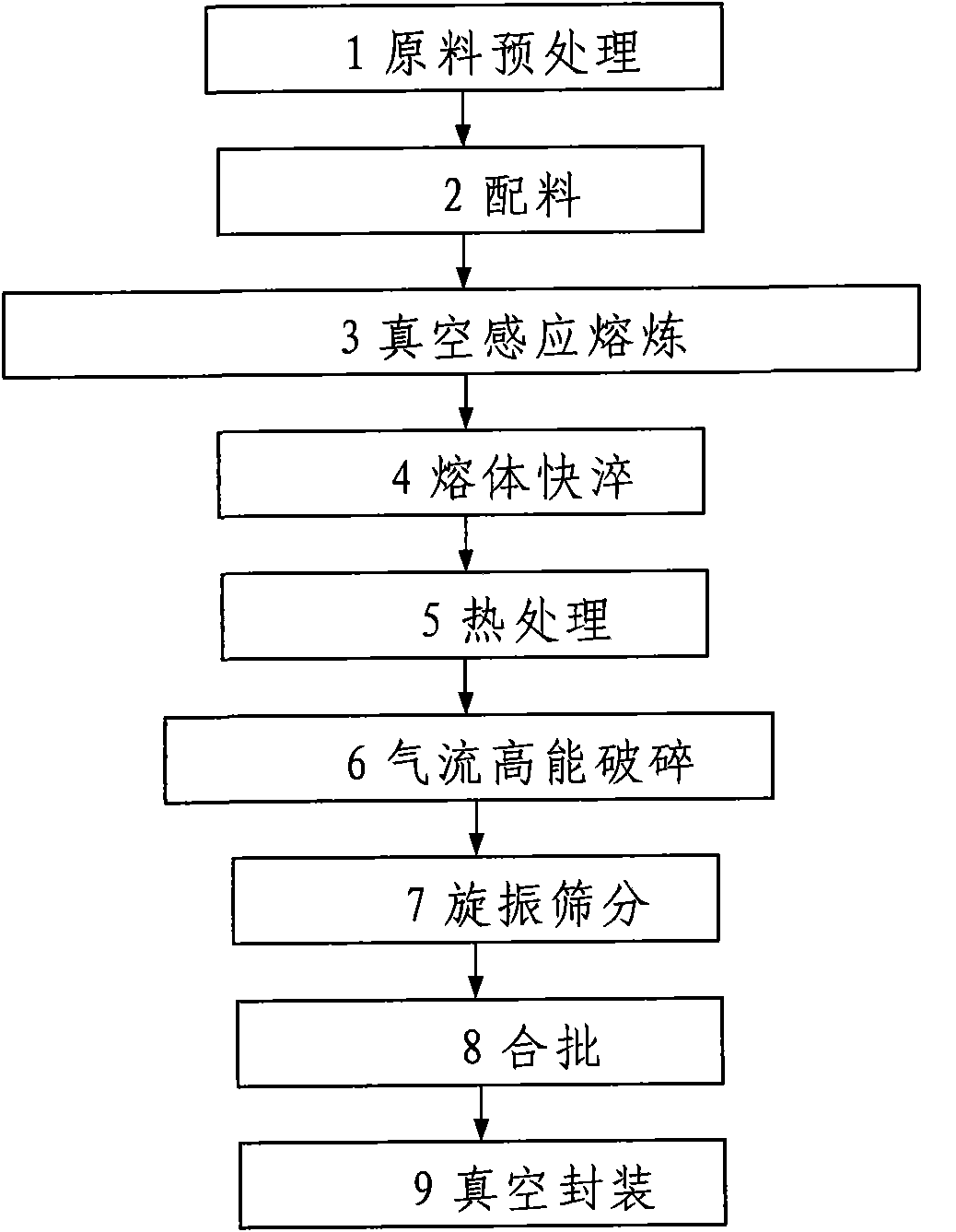

[0029] The preparation method of hydrogen storage alloy of the present invention is as image 3 As shown, it includes the following steps: 1 raw material pretreatment; 2 batching; 3 vacuum induction melting; 4 melt quenching; 5 heat treatment;

[0030] "%" in the examples is all "% by weight".

Embodiment 1

[0032] According to the designed composition La 0.62 Ce 0.27 PR 0.03 Nd 0.08 (Ni 0.81 co 0.06 mn 0.07 Al 0.06 ) 5.20 Ca 0.05 , the preparation of La (purity > 99.5%), Mm (La: 30%, Ce: 50%, Pr: 5%, Nd: 15%; La+Ce+Pr+Nd > 99%), Ca (purity > 99.5%) ), Ni (purity>99.5%), Co (purity>99.5%), Mn (purity>99.5%), Al (purity>99.5%) total 5kg. Put the raw metals into the crucible according to Al, Mn, Ni, Co, Ca, La, Mm from bottom to top. First evacuate to 5Pa, then bake and wash the furnace, fill with argon to 0.05MPa, gradually adjust the power to 4kw, 6kw, 8kw, 10kw for 5 minutes each, and then refine for 2 minutes; fill with argon to 0.05MPa, and pour the melt And through the water-cooled copper roller (line speed is 5m s -1 ) rapid cooling to obtain alloy flakes with a thickness of 0.1-0.3 mm. The rapidly quenched alloy is heat-treated at 1253K for 8 hours, and then rapidly cooled to 673K by air-cooling and quenching to obtain the heat-treated alloy. Then it is pulver...

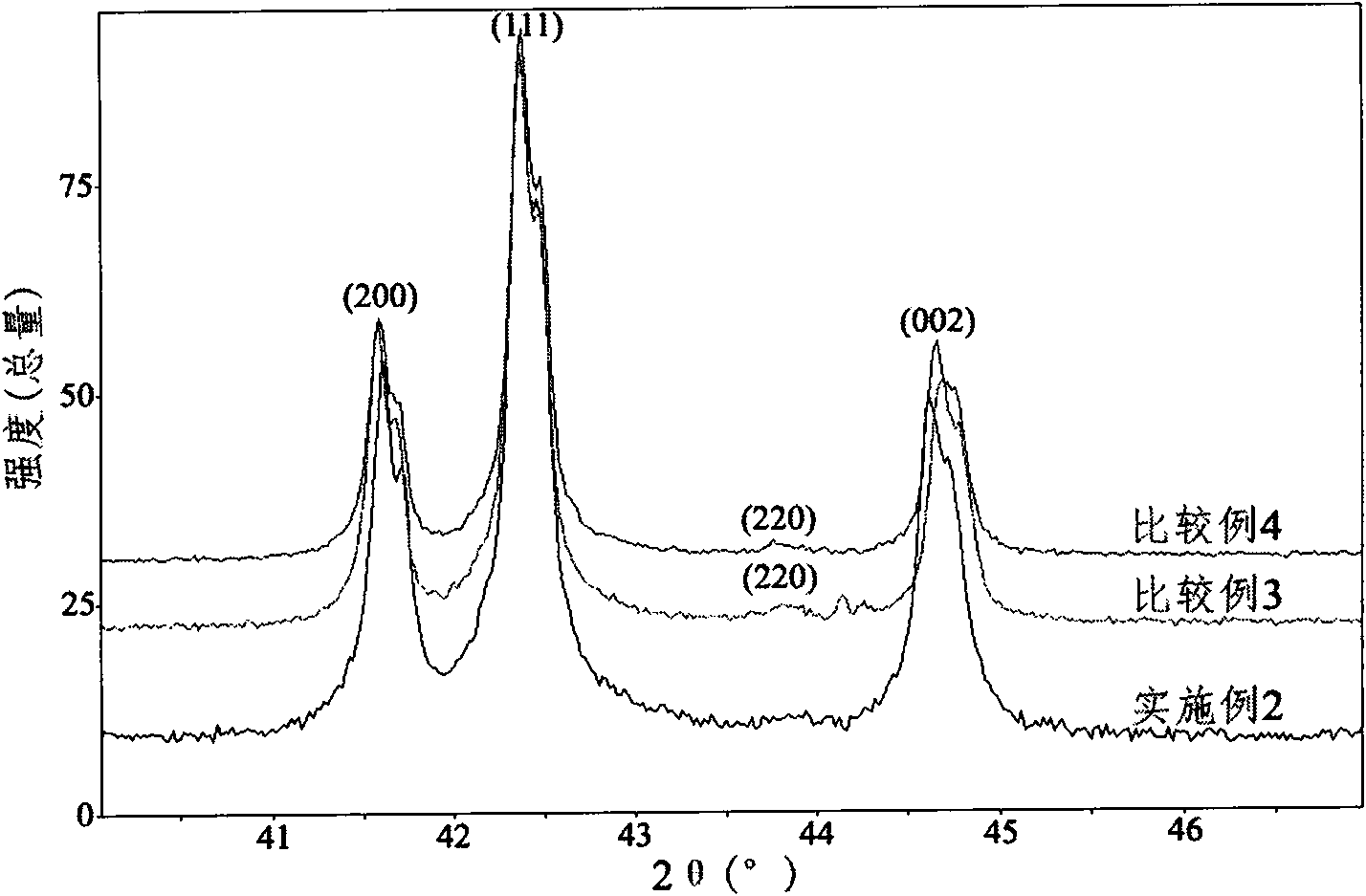

Embodiment 2

[0034] Design composition La 0.62 Ce 0.27 PR 0.03 Nd 0.08 (Ni 0.81 co 0.06 mn 0.07 Al 0.06 ) 5.20 Y 0.07 , except that the design components are different from embodiment 1, others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com