Coal ash and attapulgite compound SCR denitration catalyst and preparation method thereof

The technology of denitration catalyst and attapulgite is applied in the field of fly ash-attapulgite composite SCR denitration catalyst and its preparation, which can solve the problems of large catalyst loss and serious high temperature ablation of activated carbon, and achieves low utilization rate and strong adsorption. performance, the effect of improving denitration activity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

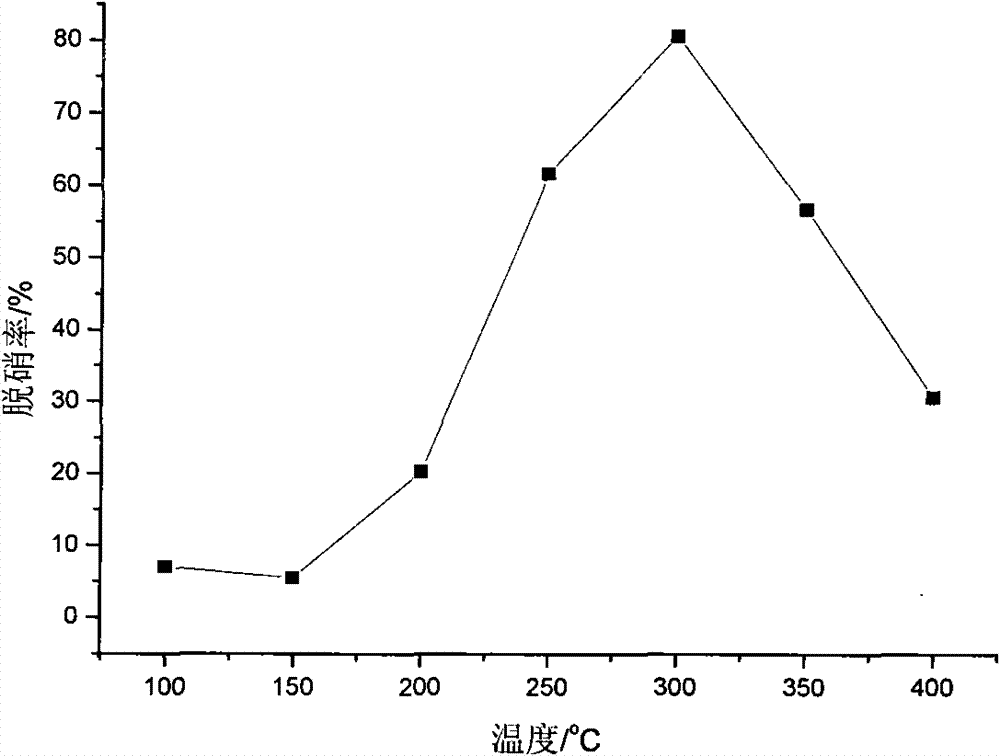

[0037] Example 1: Mn1 / FA-PG

[0038] The preparation of catalyst carrier in the present embodiment:

[0039] Mix 50g of attapulgite clay with 100g of fly ash and stir evenly to obtain a mixture, add 150mL of H2O with a mass concentration of 9-10% in the mixture 2 SO 4 Solution, add water and stir evenly, then stand still for 24 hours to obtain sample a, the amount of water added is subject to the uniform stirring; add water to sample a and stir evenly, discard the supernatant after centrifugation, repeat the operation until the supernatant pH=5-6 , to obtain sample b after discarding the supernatant; stir sample b evenly, let it stand at room temperature for 48 hours, put it into a SET type twin-screw wet extrusion granulator, and shape it into a bottom diameter of 2-3mm after mixing and extrusion , cylindrical carrier particles with a height of 3-5 mm; the cylindrical particles were dried at 50°C for 5 hours, and then dried at 105°C for 12 hours to obtain sample c, and samp...

Embodiment 2

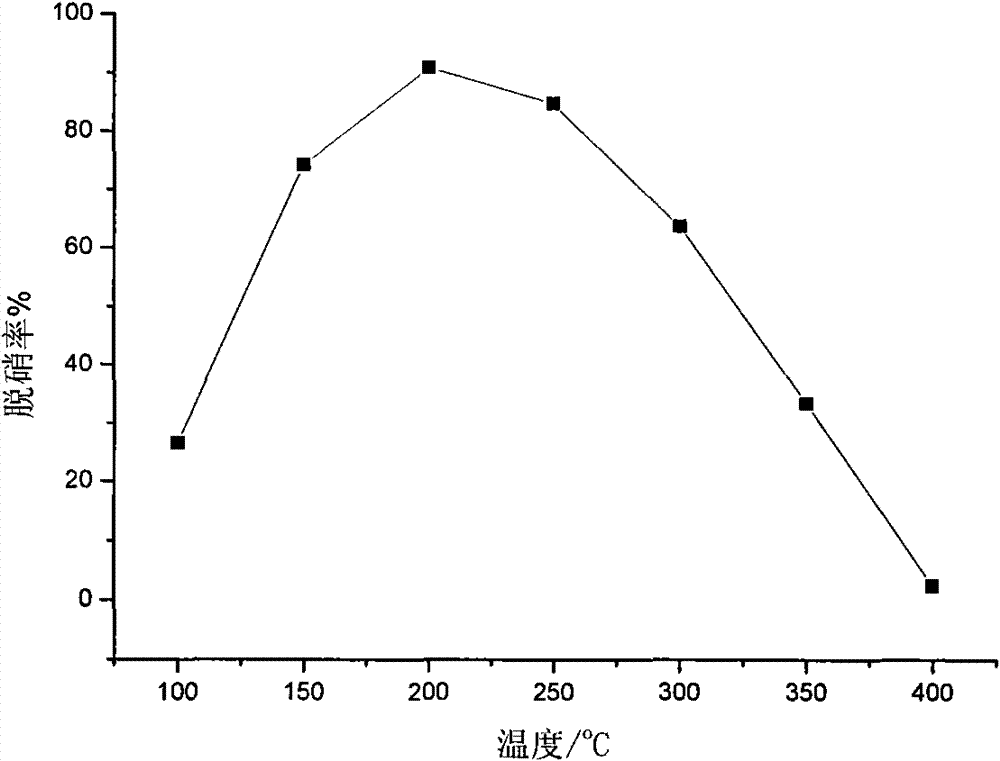

[0043] Example 2: Mn10 / FA-PG

[0044] The preparation of catalyst carrier in the present embodiment:

[0045] 50g of attapulgite clay and 50g of fly ash are mixed and stirred evenly to obtain a mixture, and 200mL of H with a mass concentration of 9-10% is added to the mixture 2 5O 4 Solution, add water and stir evenly, then stand still for 24 hours to obtain sample a, the amount of water added is subject to the uniform stirring; add water to sample a and stir evenly, discard the supernatant after centrifugation, repeat the operation until the supernatant pH=5-6 , to obtain sample b after discarding the supernatant; stir sample b evenly, let it stand at room temperature for 50 hours, put it into a SET type twin-screw wet extrusion granulator, and shape it into a bottom diameter of 2-3mm after mixing and extrusion , cylindrical carrier particles with a height of 3-5mm; the cylindrical particles were dried at 50°C for 5 hours, and then dried at 105°C for 12 hours to obtain samp...

Embodiment 3

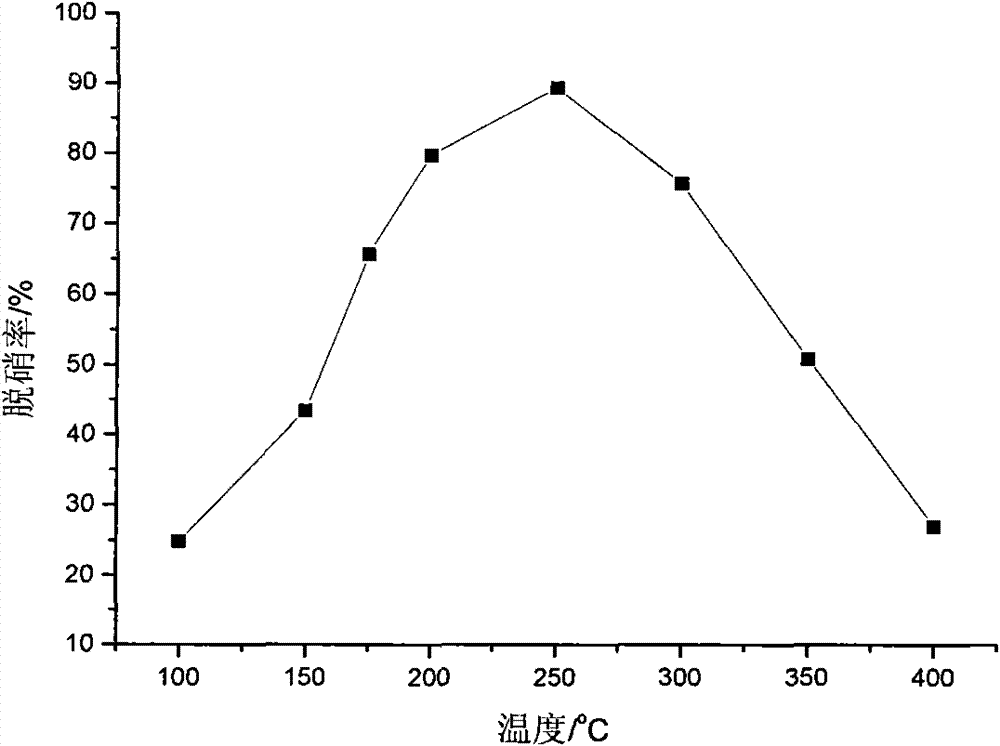

[0049] Example 3: Mn5 / FA-PG

[0050] The preparation of catalyst carrier in the present embodiment:

[0051] Mix 30g of attapulgite clay with 50g of fly ash and stir to obtain a mixture, add 80mL of 9-10% H in the mixture 2 SO 4 Solution, add water and stir evenly, then stand still for 24 hours to obtain sample a, the amount of water added is subject to the uniform stirring; add water to sample a and stir evenly, discard the supernatant after centrifugation, repeat the operation until the supernatant pH=5-6 , to obtain sample b after discarding the supernatant; stir sample b evenly, let it stand at room temperature for 60 hours, put it into a SET type twin-screw wet extrusion granulator, and shape it into a bottom diameter of 2-3mm after mixing and extrusion , cylindrical carrier particles with a height of 3-5 mm; the cylindrical particles were dried at 50°C for 5 hours, and then dried at 105°C for 12 hours to obtain sample c, and sample c was calcined at 300°C for 2 hours i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com