Semiflexible rapid leakstopping mortar with high impermeability

A semi-flexible and high-performance technology, used in the field of plugging mortar, can solve the problems of easy cracking, reduced strength of waterproof materials, short setting time, etc., to achieve the effect of anti-deformation strength, no later strength shrinkage, and improved anti-deformation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Plugging mortar formula

[0031] Sulphoaluminate cement 55%

[0032] Calcium carbonate (particle size less than 150 mesh) 33.2%

[0033] Anhydrite 5.0%

[0034] Sodium bentonite 1.8%

[0035] Melamine type superplasticizer 0.3%

[0037] Ash Calcium 3.0%

[0038] Ethylene-vinyl acetate copolymer powder 1.5%

[0039] 2. Preparation

[0040] Put each component into the mixer according to the above formula, add 32% water of the total amount of each component of the mortar, and mix evenly.

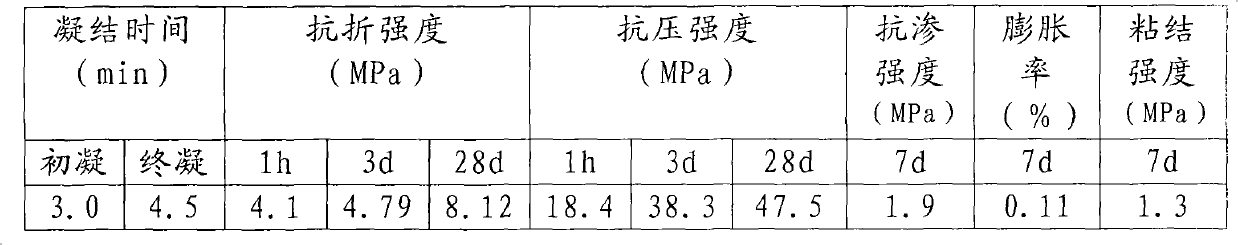

[0041] 3. Test the properties of the well-mixed plugging mortar in different time periods, and the data are as follows:

[0042]

Embodiment 2

[0044] 1. Plugging mortar formula

[0045] Sulphoaluminate cement 60%

[0046] Calcium carbonate (particle size less than 150 mesh) 29.5%

[0047] Hemihydrate gypsum 2.0%

[0048] Sodium bentonite 1.5%

[0049] Melamine type superplasticizer 0.4%

[0050] Lithium Carbonate 0.15%

[0051] Ash Calcium 4.0%

[0052] Ethylene-vinyl acetate copolymer rubber powder 2.0%

[0053] 2. Put each component into the mixer according to the above formula, add 31% water of the total amount of each component of the mortar, and mix well.

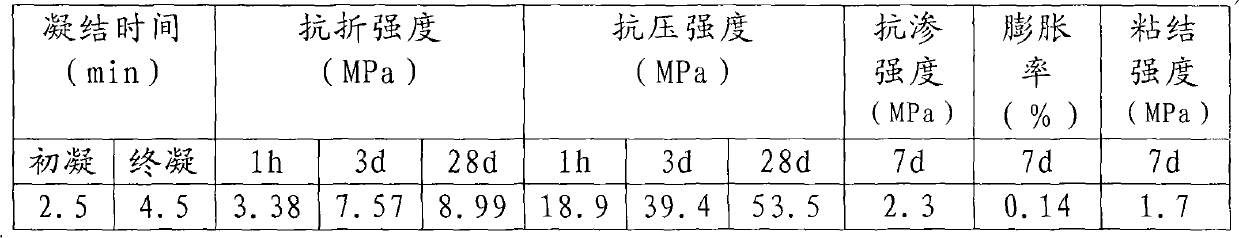

[0054] 3. Test the performance of the uniformly mixed mortar in different time periods, the data are as follows:

[0055]

[0056] From the performances measured in Examples 1 and 2, it can be seen that the plugging mortar of the present invention has fast setting time, high 1h strength, and no shrinkage in the later stage, especially the impermeability strength is close to more than 2MPa, which is unprecedented. Other indicators are also much bett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com