Method for synthesizing ceramic precursor polycarbosilane

A technology of ceramic precursor and polycarbosilane, applied in the direction of silicon organic compounds, etc., can solve the problems of low product purity, difficult to be suitable for the production and preparation of high-performance ceramic materials, etc., and achieves low alkali metal content, easy control of product structure, and high product quality. The effect of the structure is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The synthesis of embodiment 1 polycarbosilane

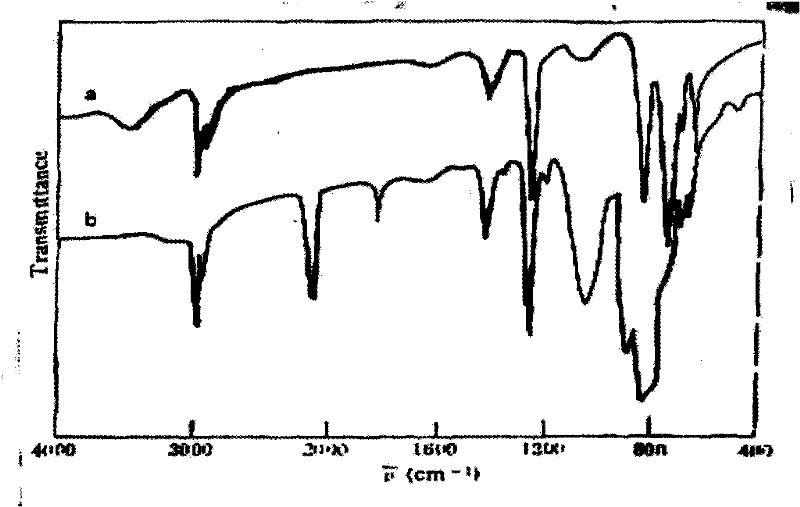

[0047] Dimethyldichlorosilane and metal sodium are polycondensed in xylene to obtain polydimethylpolysilane, which is neutralized by methanol and washed with water and dried to obtain a white solid powder; the white solid powder is cracked at 300°C to form a ring Silane-based liquid substances. figure 1 Infrared spectrum of cyclosilane.

[0048] Add 120-160 kg of CPS engineering reagents into a 300-liter rearrangement polymerization reactor with an external heating ring-opening cracking system, fill it with pure nitrogen, heat it to 300-350°C, and turn on the external heating device 300°C, strictly control the liquid reflux rate, and then fill the nitrogen system, rearrange the polymerization kettle, gradually (heating rate 0.1°C / min) to 380-470°C, and keep warm for 10-50 hours.

[0049] Stop heating, after being cooled to a certain temperature (200~250 ℃), obtain viscous tan liquid, the tan liquid is by tan liquid: xyle...

Embodiment 2

[0054] The synthesis of embodiment 2 polycarbosilane

[0055] Cyclosilane raw materials were purchased from Zhangjiagang Laibao Silicone Products R&D Center, and other raw materials were conventional reagents.

[0056] In the engineering test of adding 150 kg of CPS to a 300-liter rearrangement polymerization reactor with an external heating and ring-opening cracking system, after filling with pure nitrogen, after heating to 300-350 °C, open the external heating device 300 ~350°C, strictly control the liquid reflux rate, then fill the nitrogen system, rearrange the polymerization kettle, gradually (heating rate 0.1°C / min) to 350-500°C, and keep warm for 10-50 hours. Stop heating, after cooling to a certain temperature (100~250 ℃), obtain viscous tan polycarbosilane (PCS), it is dissolved in xylene (PCS: xylene (weight ratio)=1: 4~5 ) after fully dissolving, filter, remove the solvent in the distillation kettle, and keep warm at a vacuum degree (0.04-0.1MPa) of 200-300°C. Aft...

Embodiment 3

[0057] Synthesis and performance comparison test of embodiment 3 comparative example polycarbosilane

[0058] COMPARATIVE EXAMPLE In the 300-liter reactor of Example 1, 80-100 kg of powdery PDMS were thrown in, and polycarbosilane was prepared directly according to the conditions commonly used in the prior art.

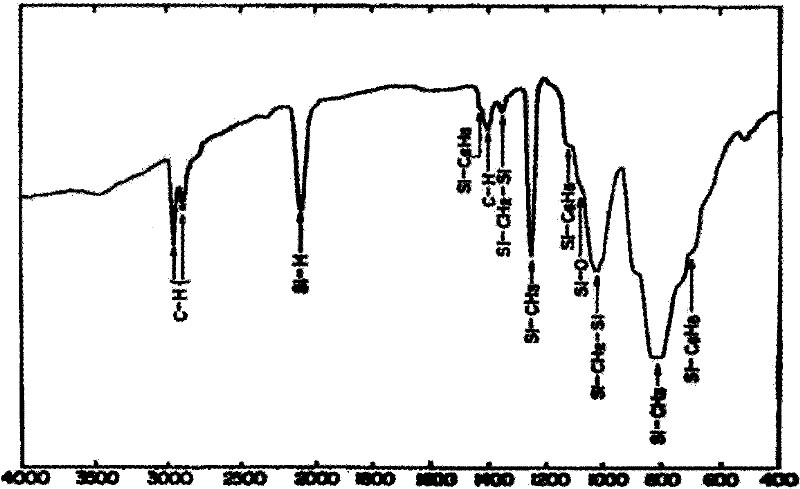

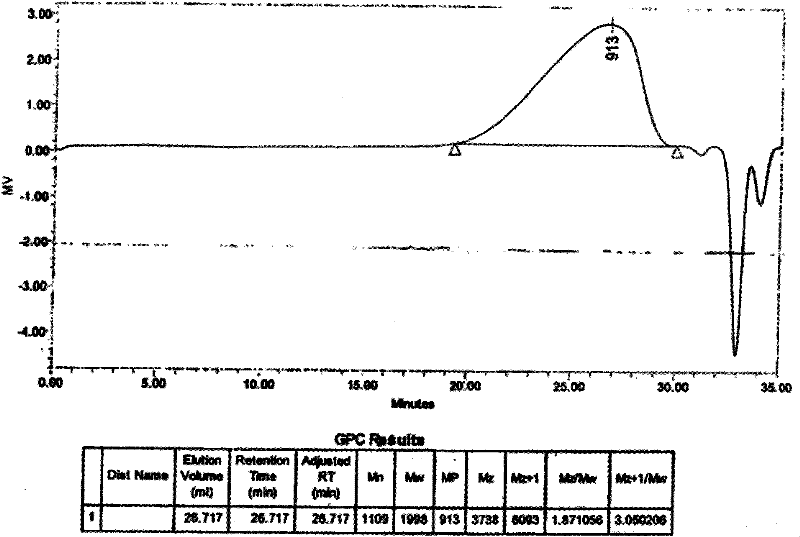

[0059] Performance test method: wherein melting point test method: microscope melting point apparatus; Molecular weight determination and distribution: GPC, solvent; Infrared spectrum measurement: in Hitachi (Hitachi) 285 grid type infrared spectrometer, KBr tablet method; Na+ determination: by Shanghai Testing center; TGA analysis with Rigaku micro-thermometer, at 10°C / min, N 2 Atmosphere, 900°C.

[0060] Under the same above-mentioned reaction conditions and in the same purification treatment process, the polycarbosilane obtained, except that the PCS melting point is slightly higher, other structures are equivalent to Example 1, but Na in the PCS molecule + The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com