Organosilicon emulsion and preparation method thereof

A technology of silicone emulsion and polyorganosiloxane, which is applied in the field of silicone emulsion and its preparation, can solve the problems that the emulsification efficiency of emulsifier needs to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

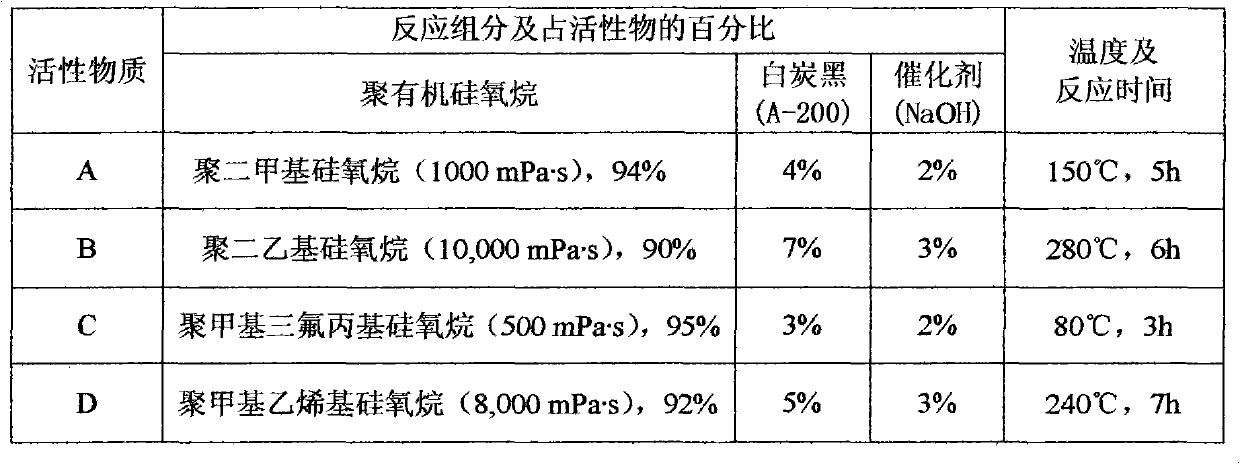

[0043] Preparation of active substances:

[0044] Active substances A, B, C, and D were prepared by using the reaction raw materials and conditions in the following table and following the preparation method of the aforementioned active substances.

[0045] Table 1

[0046]

[0047] Preparation of silicon polyether:

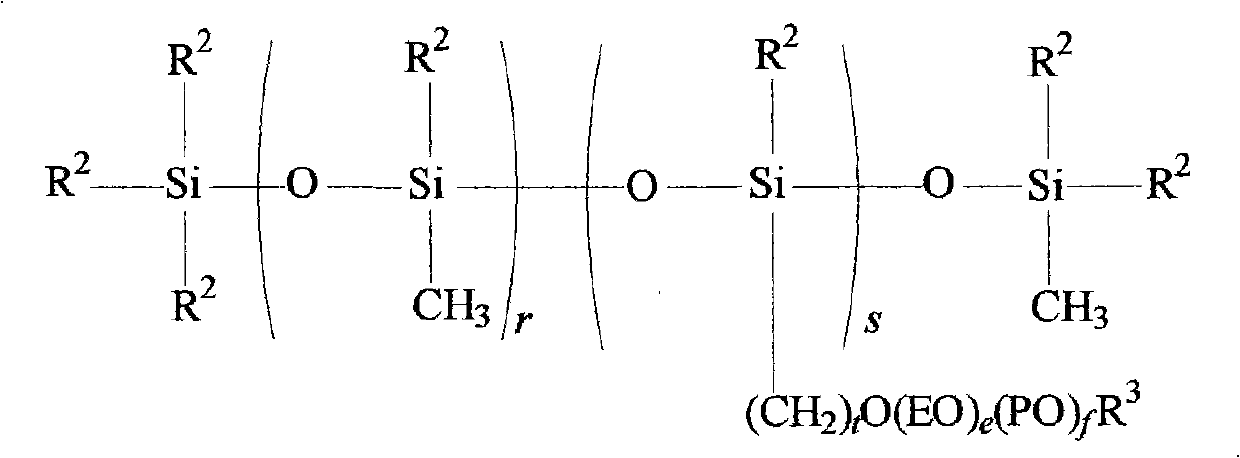

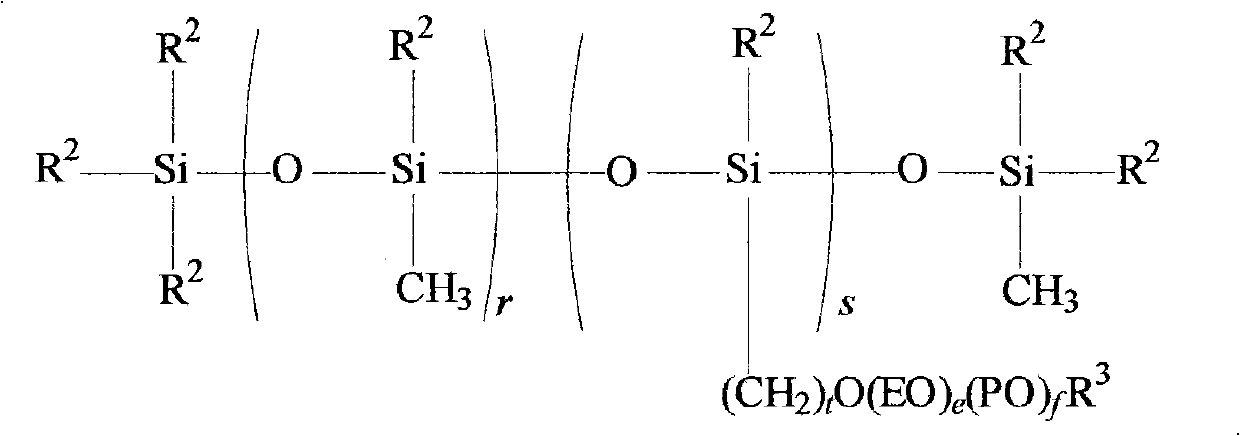

[0048] Preparation of Silicon Polyether E 1 ,E 2 ,E 3 and E 4 , whose structural formula is:

[0049]

[0050] where R 2 , R 3 , r, s, e, f, t are shown in Table 2.

[0051] Table 2

[0052] Silicon polyether

[0053] R 3

[0054] Preparation of higher fatty alcohol polyethers:

[0055] Preparation of Higher Fatty Alcohol Polyether F 1 , F 2 , F 3 and F 4 , whose general structure is R 1 O(EO) m (PO) n H, R 1 The values of , m and n are shown in Table 3.

[0056] table 3

[0057] Advanced fatty alcohol polyether

[0058] Preparation of emulsion:

Embodiment 1

[0060] The composition of the emulsion is:

[0061] Active Substance A 5%

[0062] Active Substance B 15%

[0063] Silicon polyether E 1 3%

[0064] Silicon polyether E 2 3%

[0065] Octylphenol polyoxyethylene (9) ether 0.5%

[0066] Advanced fatty alcohol polyether F 1 1.5%

[0067] Acrylic thickener 1%

[0068] Potassium sorbate 0.1%

[0069] water balance

[0070] Total 100%

[0071] At room temperature, fully mix the active material, higher fatty alcohol polyether, and silicon polyether for 35 minutes under stirring. After completion, raise the temperature of the above system to 60°C. Then, keep the system temperature, slowly add water, and increase the stirring speed Make it change from water-in-oil emulsion to oil-in-water emulsion phase inversion, continue to add water to the required mass concentration, which is 50%, the coarse emulsion is further emulsified by colloid mill, and finally diluted to solid content with acrylic...

Embodiment 2

[0073] The composition of the emulsion is:

[0074] Active Substance C 10%

[0075] Active Substance D 15%

[0076] Silicon polyether E 1 4%

[0077] Silicon polyether E 3 2.5%

[0078] Sorbitan Monooleate 1.0%

[0079] Advanced fatty alcohol polyether F 2 2.5%

[0080] Acrylic thickener 2%

[0081] Kethon 0.1%

[0082] water balance

[0083] Total 100%

[0084] At room temperature, fully mix the active material, higher fatty alcohol polyether, and silicon polyether for 40 minutes under stirring. After completion, raise the temperature of the above system to 80°C. Then, keep the system temperature, slowly add water, and increase the stirring speed Make it change from water-in-oil emulsion to oil-in-water emulsion phase inversion, continue to add water to the required mass concentration, which is 60%, the coarse emulsion is further emulsified by colloid mill, and finally diluted to solid content with acrylic acid thickening water 35% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com