Method for preparing biological coal

A coal and biological technology, applied in the direction of biofuels, waste fuels, special forms of dry distillation, etc., can solve the problems of biomass collection, transportation, storage, fire prevention difficulties, affecting large-scale use of biomass, and large volume of biomass, etc., to achieve The effect of improving energy utilization efficiency, low carbonization cost, and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A specific embodiment of a biocoal preparation method of the present invention will be further described below in conjunction with the accompanying drawings.

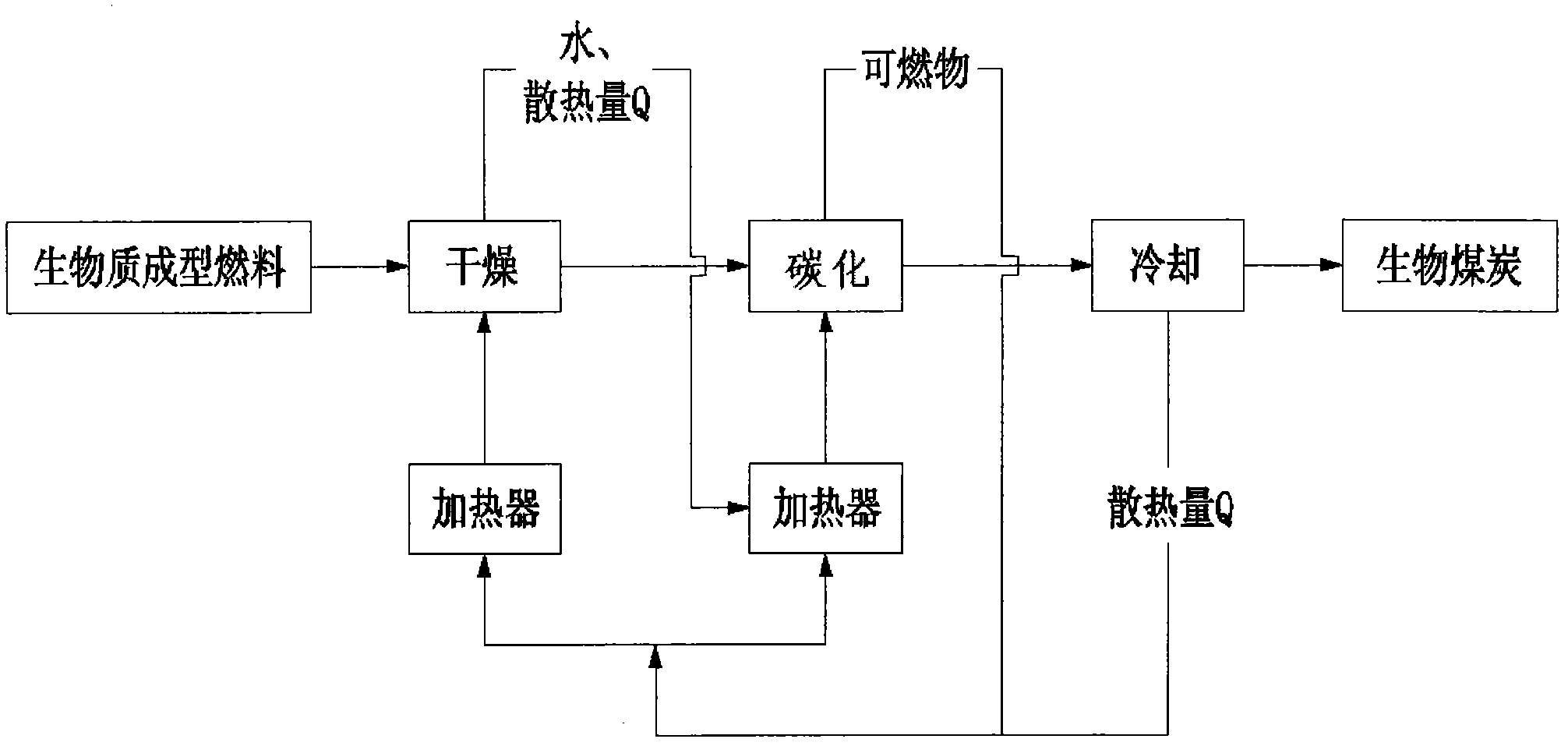

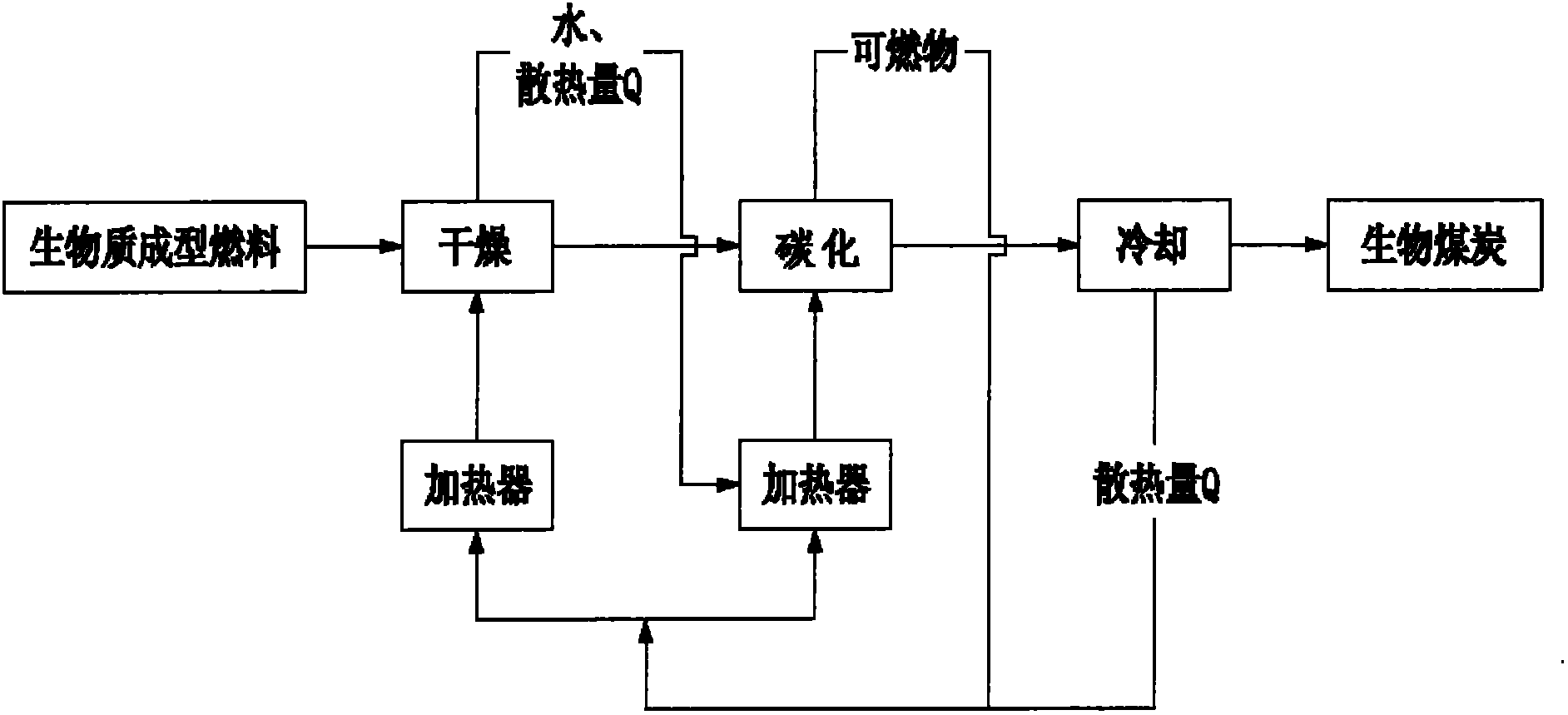

[0015] The flow chart of a biocoal preparation method of the present invention is shown in FIG. 1 .

[0016] Biomass briquette fuel is made into biocoal after drying, carbonization, cooling and other processes; the process system used in the drying, carbonization, cooling and other processing processes is similar to a sealed system, with ultra-high heat steam (or N 2 and other inert gases) as the medium, part of the steam comes from the moisture in the wet raw material; in the process, the steam and heat generated in the drying process are provided to the heater for carbonization; a small amount of pyrolysis gas generated in the carbonization process is recovered and used as fuel , to provide a heat source for the drying and carbonization process; to recover and reuse the heat released during the cooling process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com