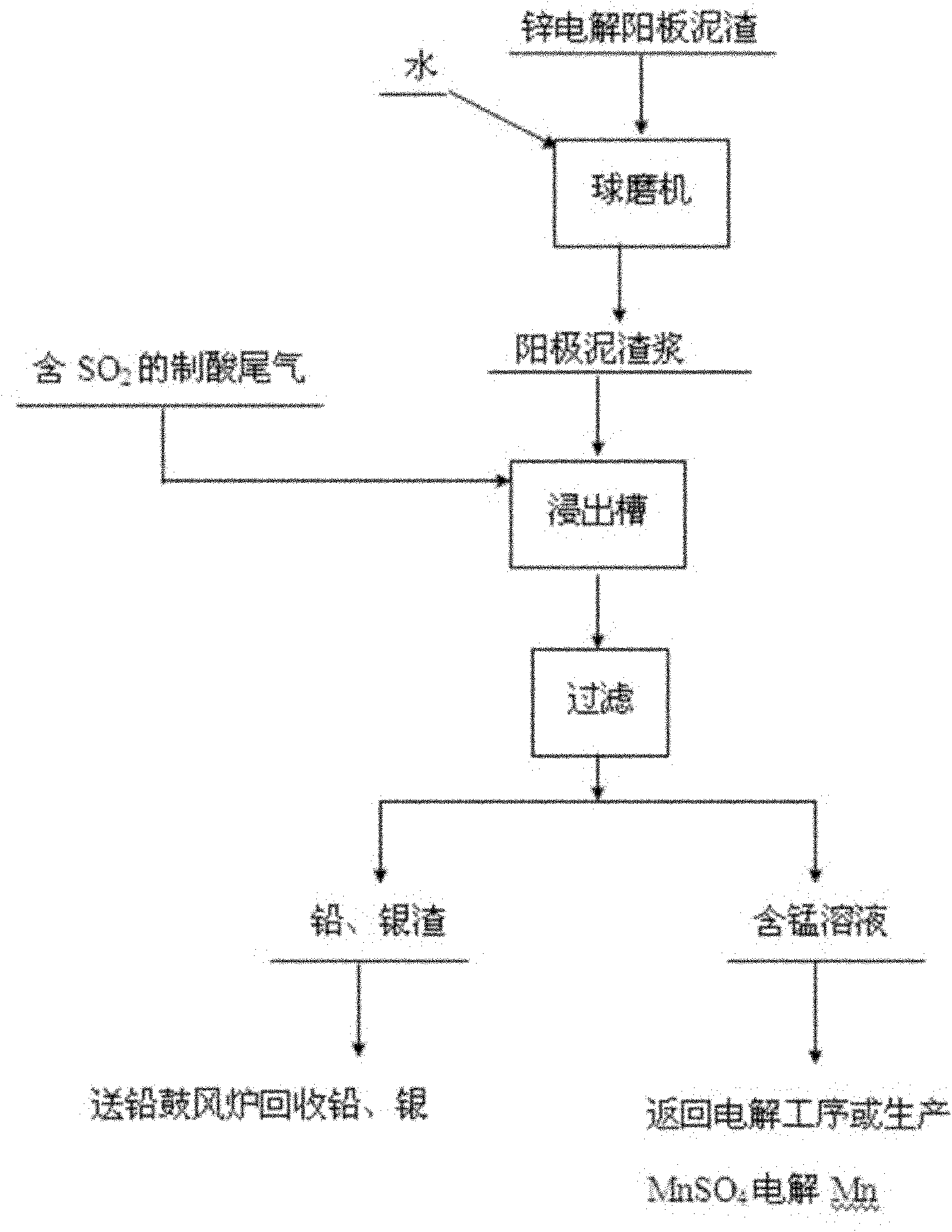

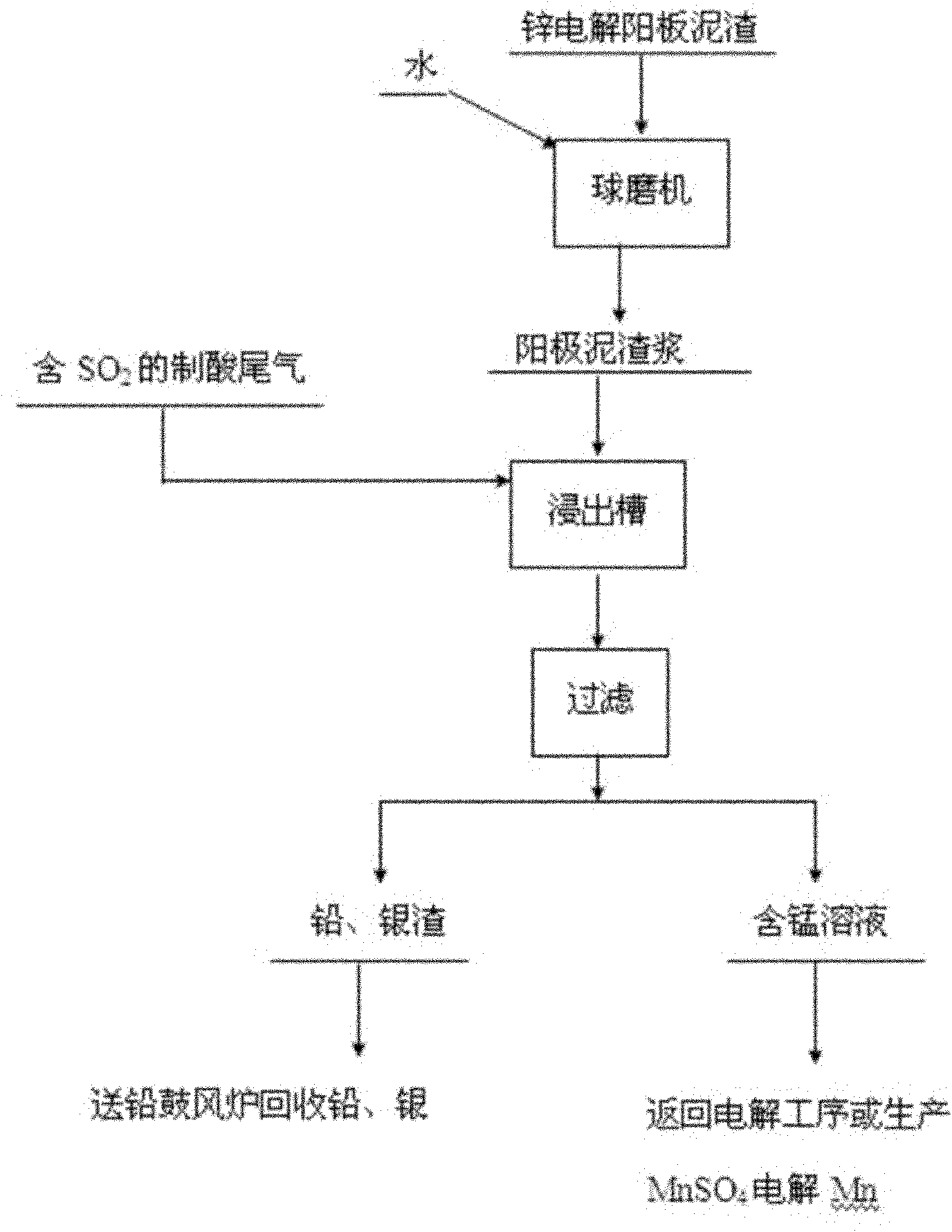

Method of recovering manganese, lead and silver from zinc electrolyzed anode mud by utilizing acid-making tail gas

A technology for making acid tail gas and anode slime, which is applied in the fields of silver, manganese and lead recovery, which can solve the problems of difficulty in recycling, lack of recycling, high cost of electrolytic zinc, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] Composition of zinc electrolysis anode sludge: manganese 52%, lead 17%, silver 1100 g / ton, slurry volume 5 liters, water: anode sludge = 4: 1 (i.e. liquid-solid ratio = 4: 1), tail gas concentration: Contains SO 2 3%, SO 2 Air flow 1m 3 / min, temperature: room temperature, through SO 2 Time: 4 hours, concentration of manganese-containing solution: manganese ion 106 g / liter, composition of lead and silver slag: manganese 2.8%, lead 49.6%, silver 2300 g / ton.

example 2

[0026] Exhaust gas concentration: containing SO 2 0.5%, SO 2 Airflow 1.1m 3 / min, temperature: room temperature, through SO 2 Time: 5 hours, concentration of manganese-containing solution: 105 g / liter of manganese ion, composition of lead and silver slag: 2.1% of manganese, 49.8% of lead, 2380 g / ton of silver, all the other are the same as example 1.

example 3

[0028] Exhaust gas concentration: containing SO 2 0.05%, SO 2 Airflow 1.6m 3 / min, temperature: room temperature, through SO 2 Time: 10 hours, concentration of manganese-containing solution: 105 g / liter of manganese ion, composition of lead and silver slag: 2.1% of manganese, 48.6% of lead, 2370 g / ton of silver, all the other are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com