Composite additive for producing electrolytic copper foil with high bending resistance and low outline

A compound additive, electrolytic copper foil technology, applied in the electrolytic process, electroforming and other directions, can solve the problems of high cost, low profile and bending resistance, complex processing technology of rolled copper foil, etc. The effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

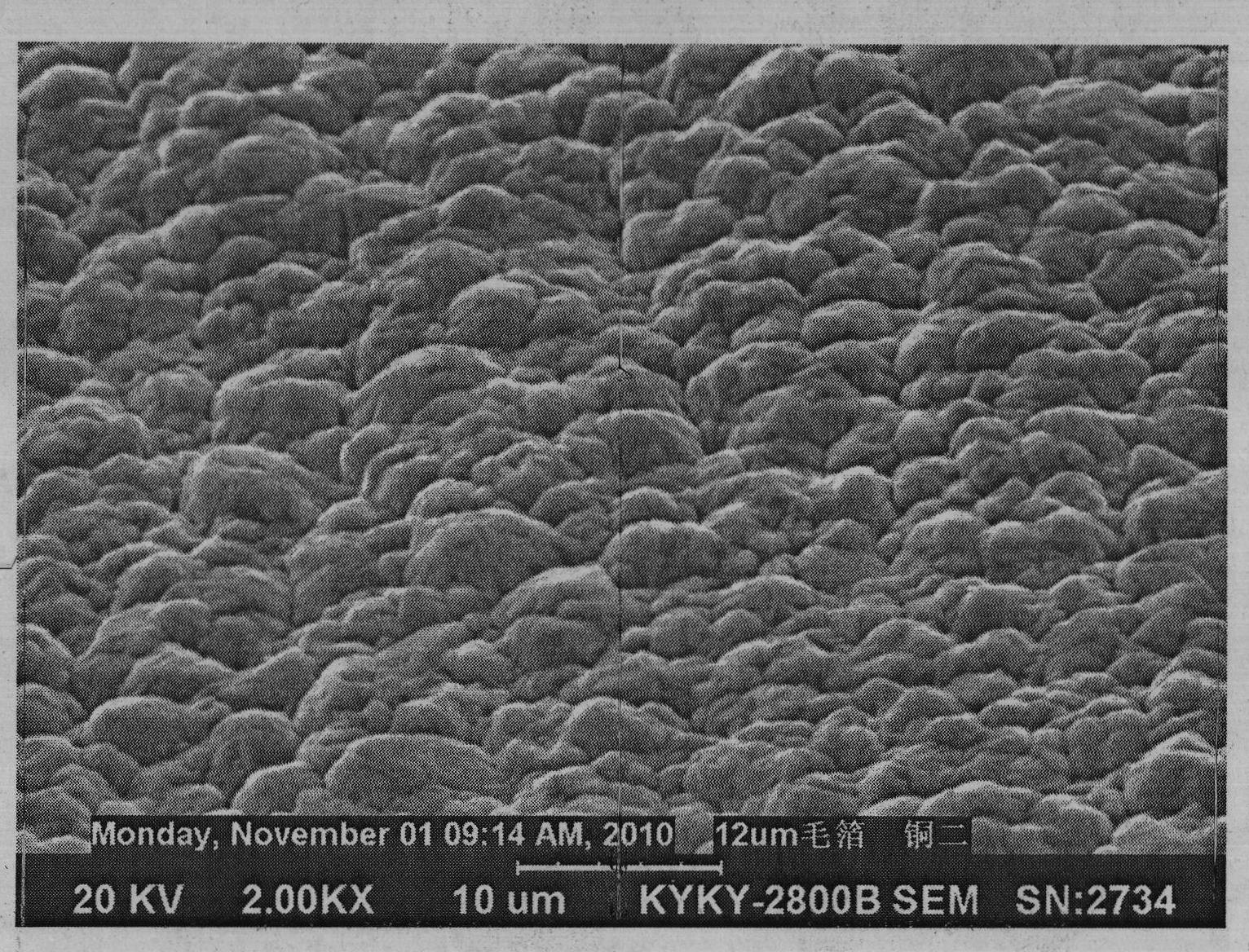

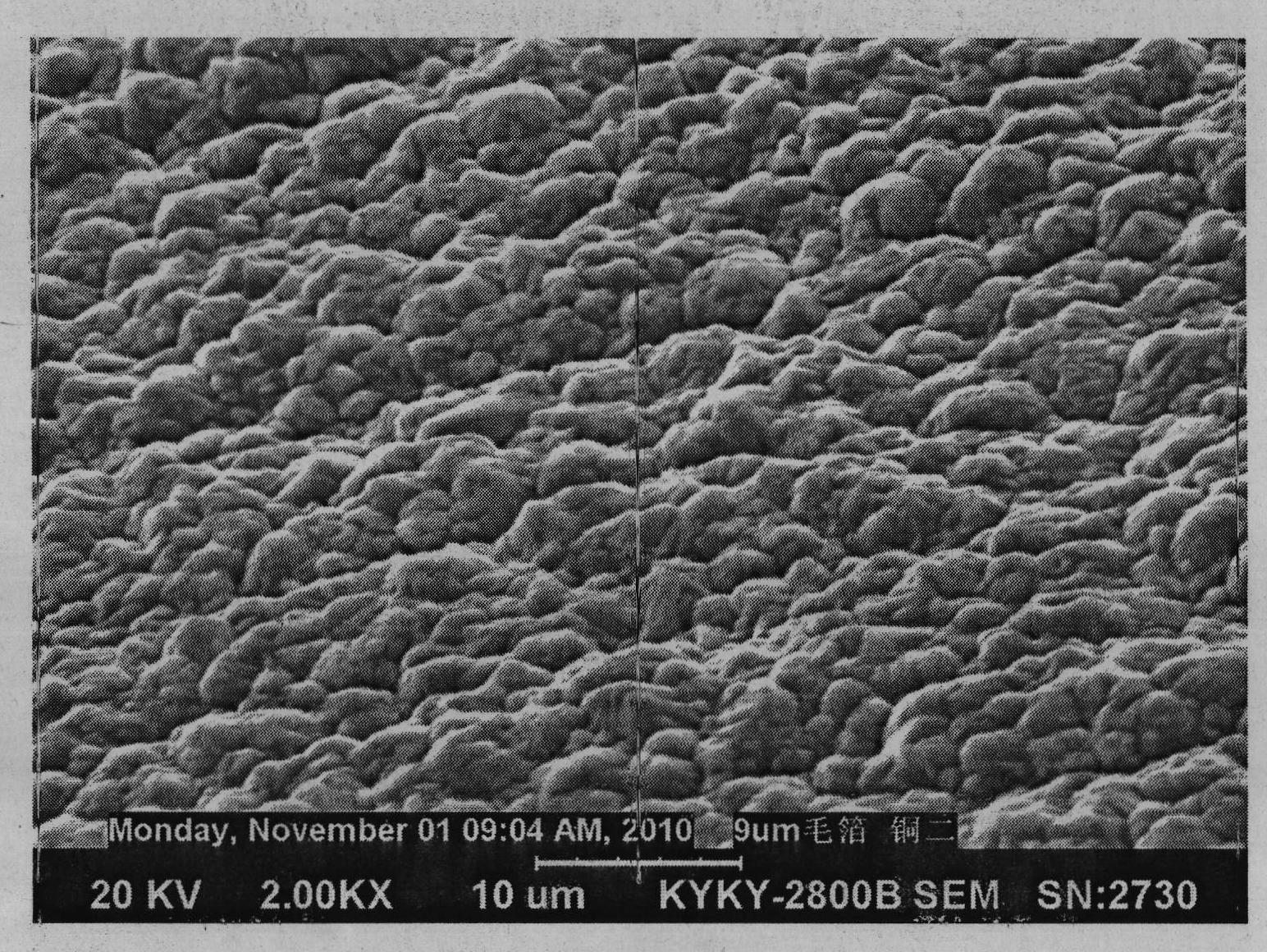

Image

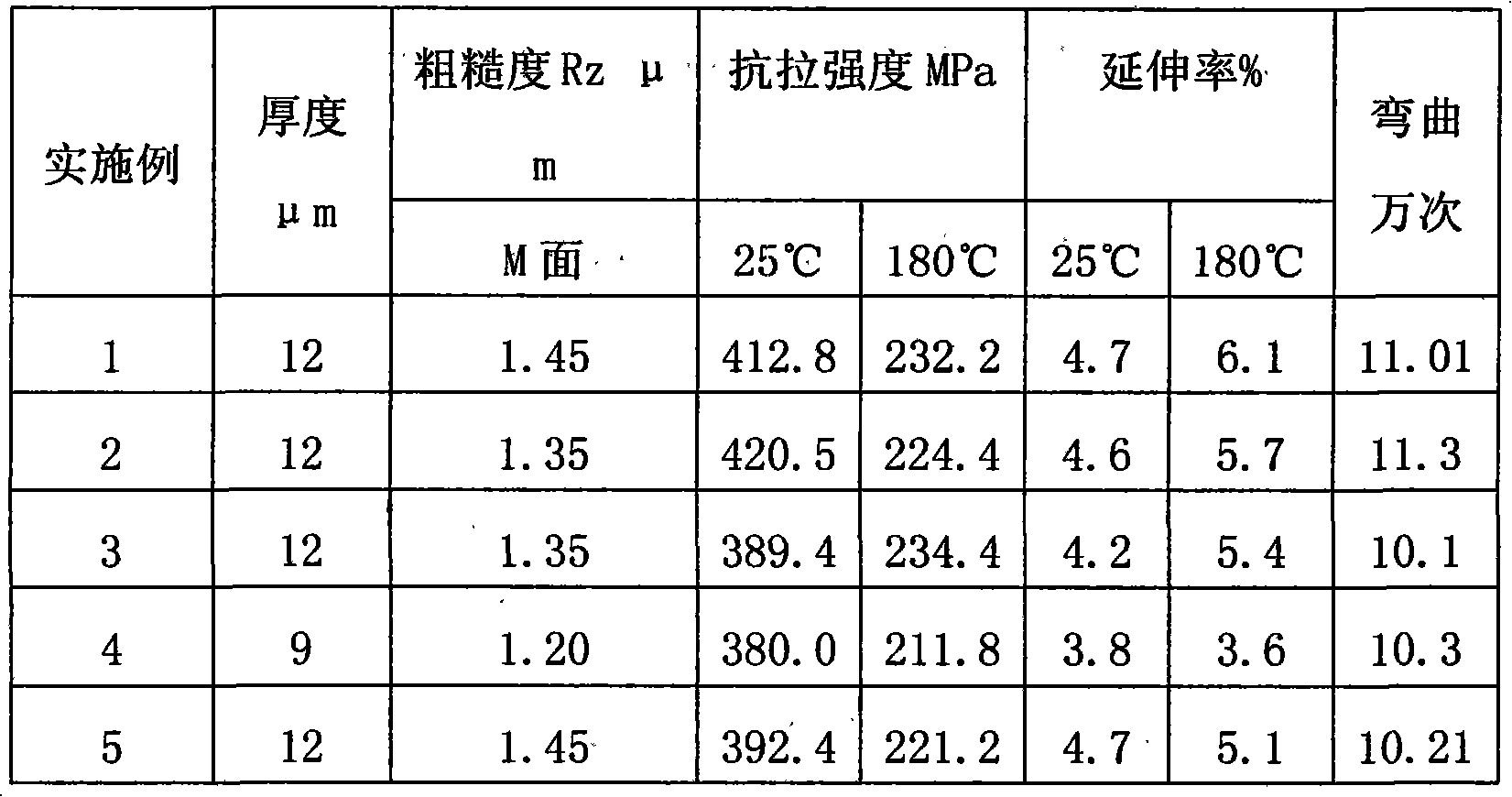

Examples

Embodiment 1

[0021] Example 1: A composite additive that can be used to produce high bending resistance and low-profile electrolytic copper foil. Each liter of aqueous solution of the composite additive contains 40 mg of hydroxyethyl cellulose ether, 10 mg of gelatin, and thiazoline-based dithiopropane sulfonate Sodium dibutyl succinate 5mg, sodium dibutyl succinate sulfonate 50mg.

Embodiment 2

[0022] Example 2: A composite additive that can be used to produce high bending resistance and low-profile electrolytic copper foil. The aqueous solution of the composite additive contains 90 mg of hydroxyethyl methyl cellulose ether, 50 mg of gelatin, and thiazoline-based dithio Sodium propane sulfonate 25mg, sodium dipentyl succinate sulfonate 500mg.

Embodiment 3

[0023] Example 3: A composite additive that can be used to produce high bending resistance and low-profile electrolytic copper foil, containing 50 mg of hydroxypropyl cellulose ether, 20 mg of gelatin, and thiazoline-based dithiopropane sulfonate in every liter of aqueous solution of the composite additive Sodium sulfonate 10mg, sodium dipentyl succinate sulfonate 60mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness of matte surface | aaaaa | aaaaa |

| Normal temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com