Wet lay-up and edge-jointing construction method of single-sided adhesive wet lay-up waterproof coiled material

A technology of waterproofing membrane and construction method, which is applied to tools used in roofing engineering, roofing, earthwork drilling and mining, etc. It can solve problems such as inability to bond, high cost of double-sided adhesive waterproofing membranes, and leakage of joint surfaces, and achieve The effect of firm bonding, irreversible connection of flesh and blood, and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

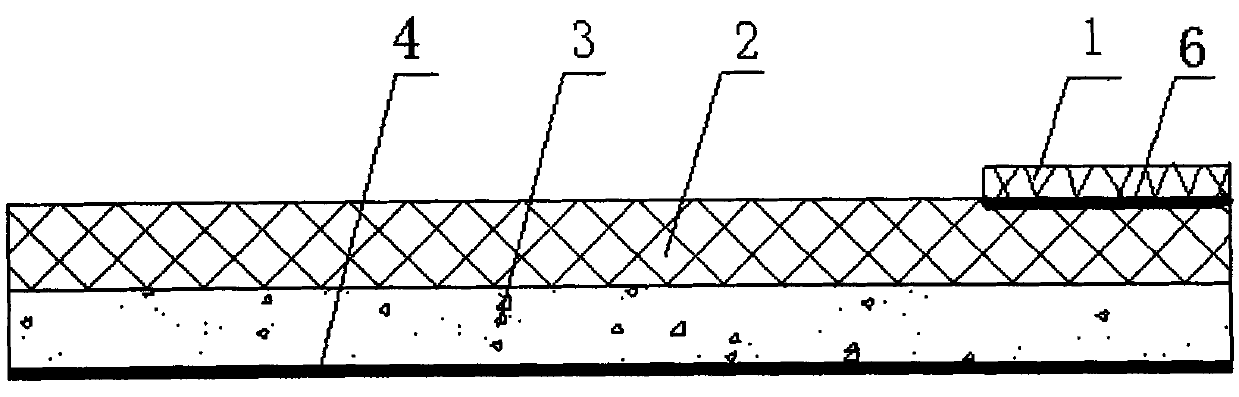

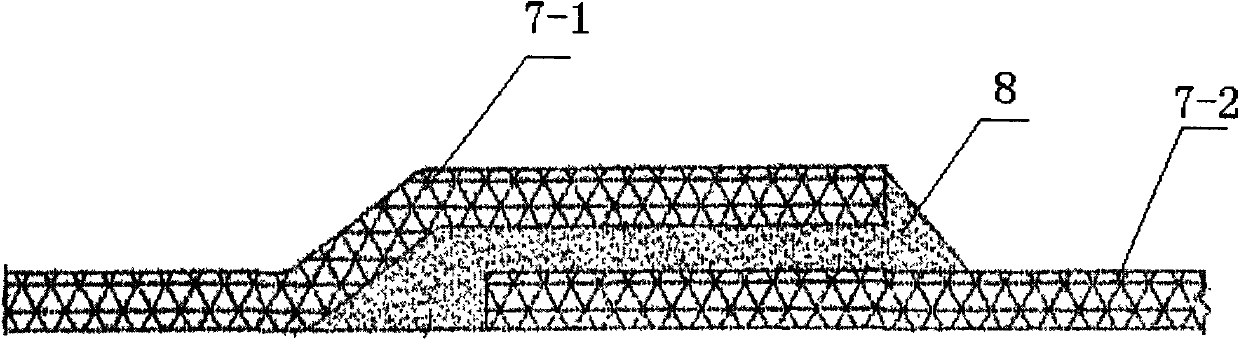

[0036] The construction of the parking lot in the basement of a 28-storey residential building in a certain city in Guangxi requires waterproof reinforcement due to the abundance of groundwater. Modified asphalt reactive adhesive or self-adhesive adhesive and isolation protective film, when wet-laying waterproof membranes, tear off the isolation protective film covered at the joints, and directly carry out wet-laying joints; the construction method is first on the ground Lay a layer of concrete with a thickness of 30 cm, and then wet-lay the waterproof membrane. Each section (one piece) of waterproof membrane is laid, and the two ends and both sides are joined. The waterproof membrane 7-2 is wet-laid on the concrete structure layer. When wet-laying the waterproof membrane, first scrape or roll to remove the air at the bottom to ensure that the pavement is smooth, tear off the covering protective film to expose the CPS film on the edge, and then wet-lay the other side layer befo...

Embodiment 2

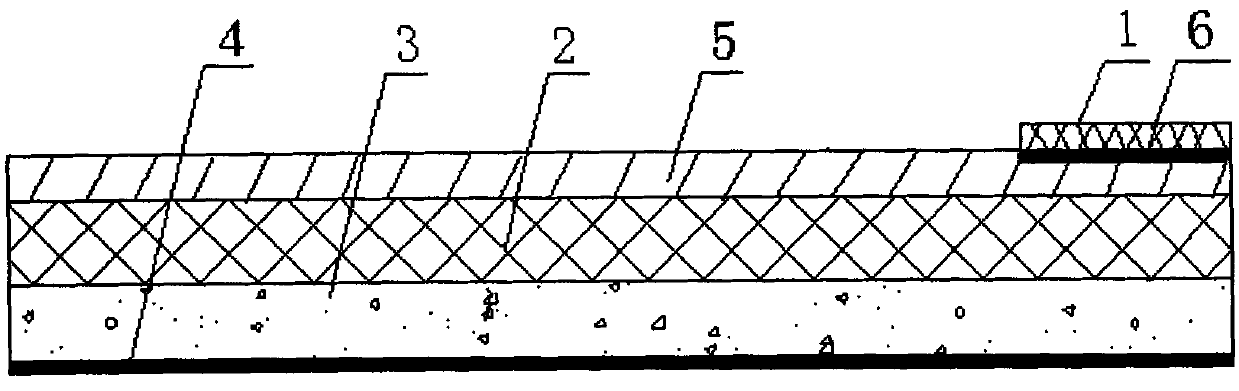

[0038] In January 2010, during the construction of the roof of a building in Guangxi, the inventor prepared a waterproof coiled material in advance, (the waterproof coiled material is a CPS film on the bottom surface, and is covered with a protective film. The protective film is torn off during use, and the double-sided adhesive tape 9 exposed), dry-lay wet-laid waterproofing membrane with a width of 60-100mm or double-sided adhesive at the edge of the single-sided wet-laid waterproofing membrane, and then wet-laid the edge, and the cross part is laminated by the adhesive to form For the large-area waterproof membrane layer, the construction method is to wet-lay the waterproof membrane 7-2 on the concrete structure layer. When the waterproof membrane is wet-laid, it is first scraped or rolled to remove the air at the bottom to ensure that the pavement Smooth, before the cement solidifies, then wet-lay the other side layer of waterproof membrane 7-1, and the intersection part is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com