Method for preparing adhesive pellets by extrusion and spheronization

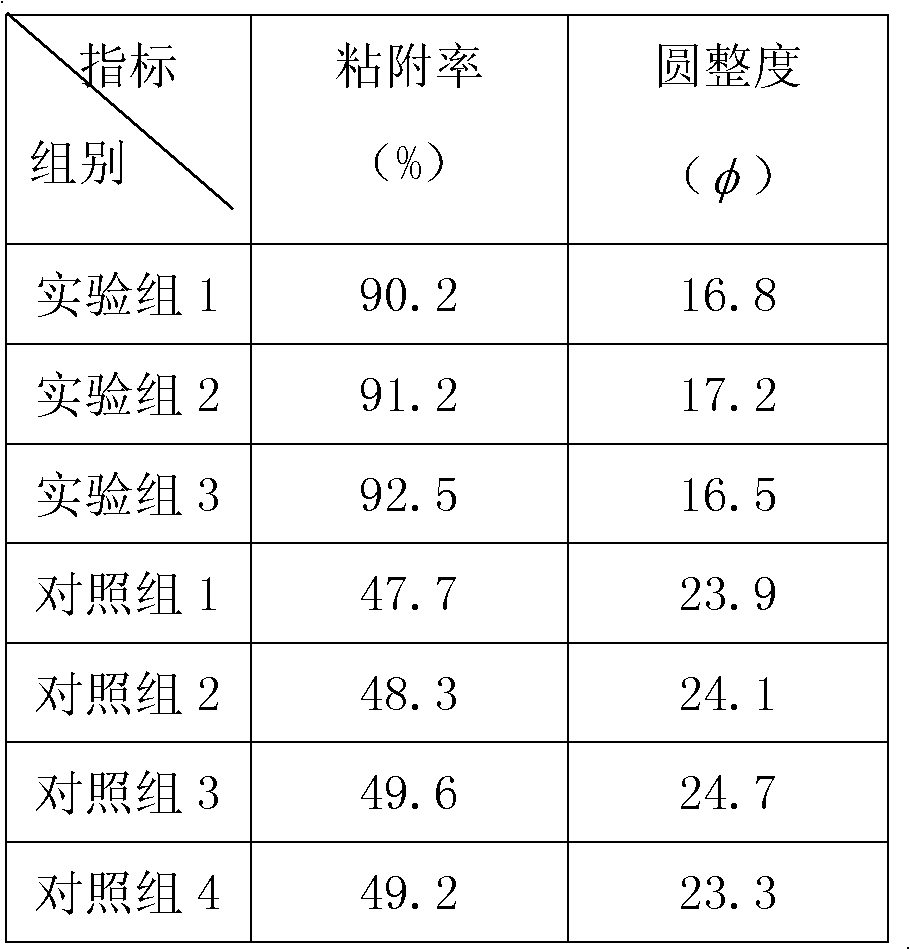

A technology of extrusion spheronization and pellets, which is applied in the direction of medical preparations of non-active ingredients, devices for making drugs into special physical or taking forms, and pharmaceutical formulations, which can solve the problem of adhesion of adhesives and pellets. Adhesion performance and toughness reduction, poor roundness of pills and other problems, to achieve the effect of improved adhesion performance, prolonged residence time, and good roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Present embodiment is a kind of preparation method of leech adhesion pellet, and this method is as follows:

[0020] 1) Take 5g of dry powder of leech extract, add 145g of microcrystalline cellulose and 5g of lactose, and mix uniformly by the method of equal increments, pass through a 100-mesh sieve, add 100mL of water to prepare a soft material and place it in an extrusion-spheronizer to extrude The technological parameters of speed 20rpm, spheronization speed 200rpm and spheronization time 5min were extruded and spheronized, then dried at 50°C for 18h, and passed through a 30-mesh sieve to obtain leech-loaded pellets.

[0021] 2) Place the obtained pellets in a coating pan, add powder mixed with 5 g of hypromellose and 95 g of microcrystalline cellulose, spray with an appropriate amount of water to moisten, and adopt a powder layer coating method at 70°C Wrap the powder on the surface of the pellets loaded with leeches, and then place them in an oven at 40° C. and dry...

example 2

[0023] This embodiment is a preparation method of matrine adhered pellets, the method is as follows:

[0024] 1) Take 10g of matrine, add 100g of microcrystalline cellulose, 5g of lactose, and 5g of starch, mix uniformly by the method of equal increments, pass through a 100-mesh sieve, add 190mL of water to prepare a soft material, put it in an extrusion-spheronizer, and The technological parameters of extrusion speed 25rpm, spheronization speed 250rpm and spheronization time 7min were extruded and spheronized, then dried at 50°C for 20h, and passed through a 30-mesh sieve to obtain matrine-loaded pellets.

[0025] 2) Place the obtained pellets in a coating pan, add powder mixed with 3 g of carbomer and 55 g of microcrystalline cellulose, spray it with an appropriate amount of water to moisten it, and apply a powder layer coating method at 70° C. The above-mentioned powder was wrapped on the surface of the matrine-loaded pellets, and then dried in an oven at 40° C. for 12 hour...

example 3

[0027] Present embodiment is a kind of preparation method of metronidazole adhesion pellet, and the method is as follows:

[0028] 1) Take 7.5g of metronidazole, add 95g of microcrystalline cellulose, 2.5g of lactose, and 2.5g of starch, mix uniformly by using the method of equal increments, pass through a 100-mesh sieve, add 75mL of water to prepare a soft material and place it in an extrusion-spheronizer In the process, extrude and spheronize with the technological parameters of extrusion speed 15rpm, spheronization speed 150rpm and spheronization time 3min, then dry at 50°C for 20h, and pass through a 30-mesh sieve to obtain pellets loaded with metronidazole.

[0029] 2) Put the obtained micropellets in a coating pan, add 2.5g of hypromellose, 2.5g of carbomer and 90g of microcrystalline cellulose powder, spray with an appropriate amount of water to moisten, and put them under the condition of 70°C The powder was coated on the surface of the metronidazole-loaded pellets by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com