Aluminium-based compound capable of having hydrolysis reaction under neutral and normal temperature conditions to produce hydrogen and preparation method thereof

An aluminum-based compound, hydrolysis hydrogen production technology, applied in the production of hydrogen, etc., to achieve the effect of accelerating the reaction rate of aluminum hydrolysis, no environmental pollution, and increasing the yield of hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

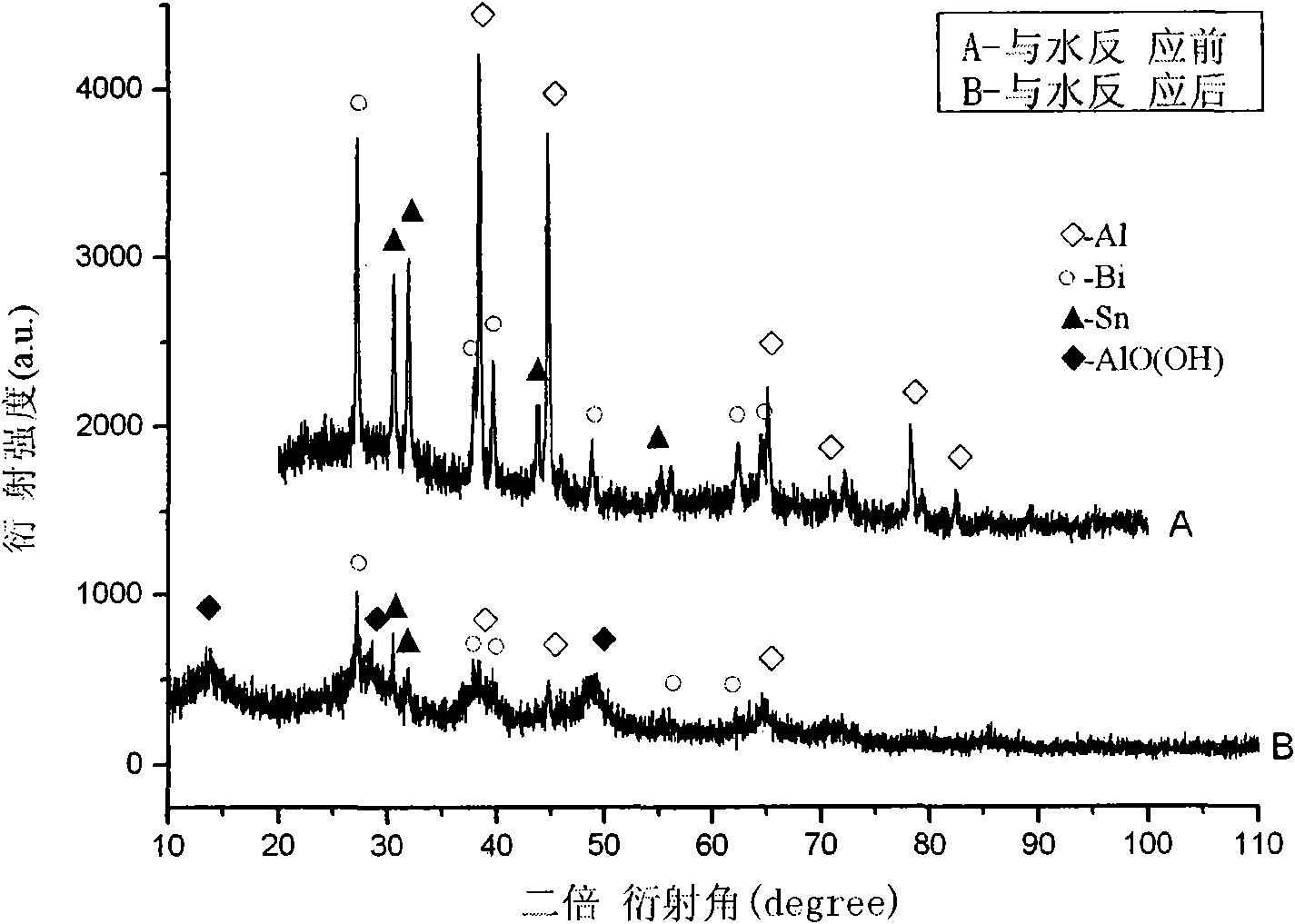

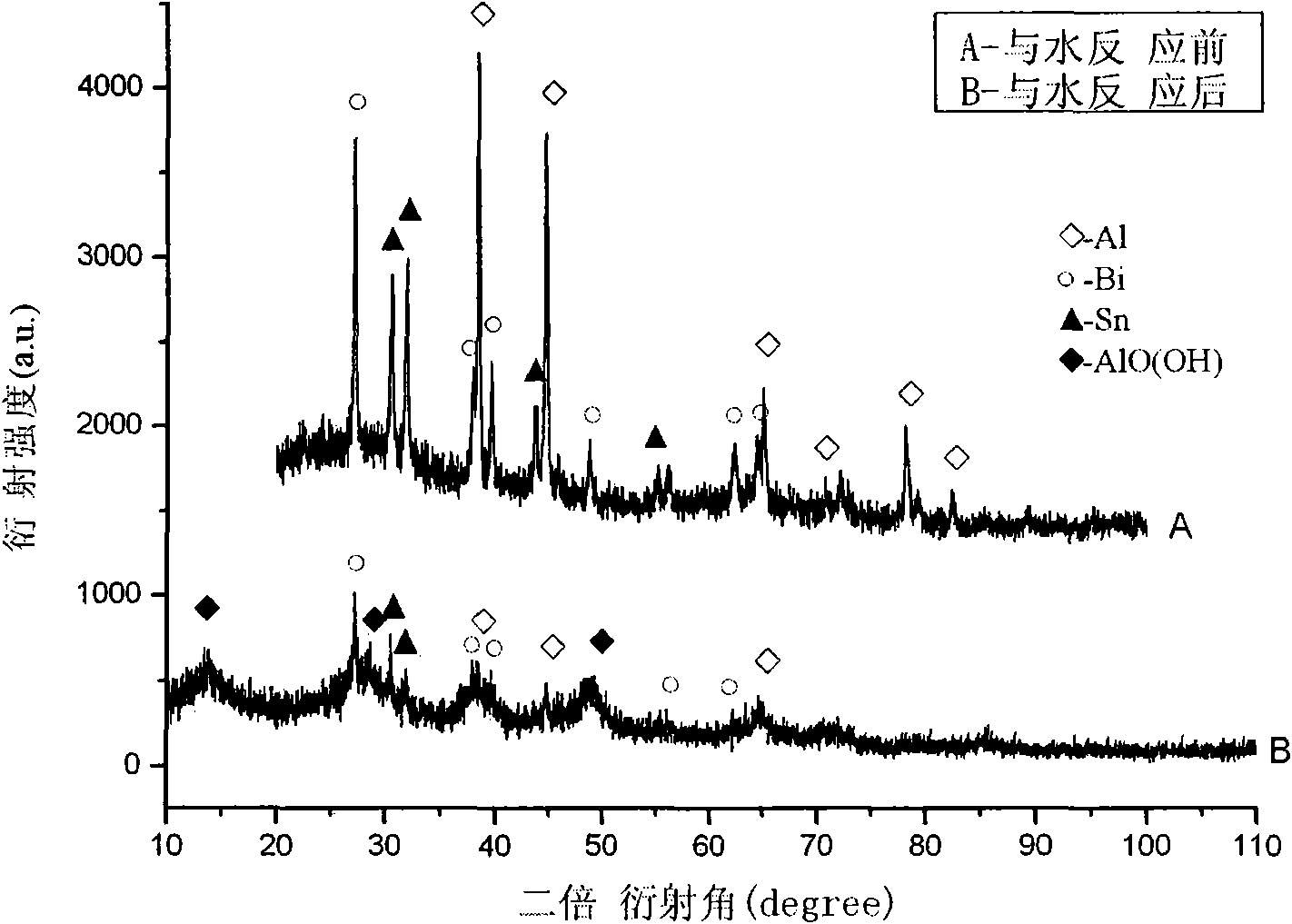

[0013] Bismuth powder and tin powder are evenly mixed in a mass ratio of 1:1, and pressed into a cylindrical shape in a steel mold. Put the cylindrical bismuth powder-tin powder mixture into a vacuum electric arc furnace for smelting four times, and then spin it on a vacuum strip machine to obtain bismuth-tin amorphous or nanocrystalline alloy thin strips. 2~3um metal pure aluminum powder and bismuth-tin amorphous or nanocrystalline alloy thin strips are put into a stainless steel ball mill tank at a mass ratio of 100:20, and the aluminum matrix composite is obtained after ball milling under the protection of a high-purity Ar atmosphere for 16 hours. thing. Add the aluminum-based composite to pure water at 30°C, and continue to react with water. The reaction is completed within 10 minutes, and the actual hydrogen production rate of the aluminum powder is as high as 93.4%. The product is aluminum oxyhydroxide that can be recycled, and the aluminum-based composite The XRD patte...

Embodiment 2

[0015] Bismuth powder and indium powder are uniformly mixed at a mass ratio of 3:7, and pressed into a cylindrical shape in a steel mold. The cylindrical bismuth powder-indium powder mixture is smelted in a vacuum electric arc furnace for 4 times, and then stripped on a vacuum strip machine to obtain bismuth-indium amorphous or nanocrystalline alloy thin strips. 2~3um metal pure aluminum powder and bismuth-indium amorphous or nanocrystalline alloy thin strips are put into a stainless steel ball mill tank at a mass ratio of 100:10, and the aluminum matrix composite is obtained after ball milling under the protection of a high-purity Ar atmosphere for 24 hours. thing. Add the aluminum-based composite to pure water at 20°C, and continue to react with the water. The reaction is completed within 20 minutes. The actual hydrogen production rate of the aluminum powder is about 78%, and the product is aluminum oxyhydroxide that can be recycled.

Embodiment 3

[0017] Bismuth powder, tin powder and zinc powder are uniformly mixed in a mass ratio of 5:4:1, and pressed into a cylindrical shape in a steel mold. The cylindrical bismuth-tin-zinc powder mixture is smelted in a vacuum electric arc furnace for 4 times, and then stripped on a vacuum strip machine to obtain bismuth-tin-zinc amorphous or nanocrystalline alloy thin strips. 4~6um metal pure aluminum powder and bismuth-tin-zinc amorphous or nanocrystalline alloy thin strips are put into a stainless steel ball mill tank at a mass ratio of 100:5, and aluminum is obtained after ball milling under the protection of a high-purity Ar atmosphere for 16 hours. base complex. Add the aluminum-based composite to pure water at 20°C, and continue to react with the water. The reaction is completed within 15 minutes. The actual hydrogen production rate of the aluminum powder is about 83%, and the product is aluminum oxyhydroxide that can be recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com