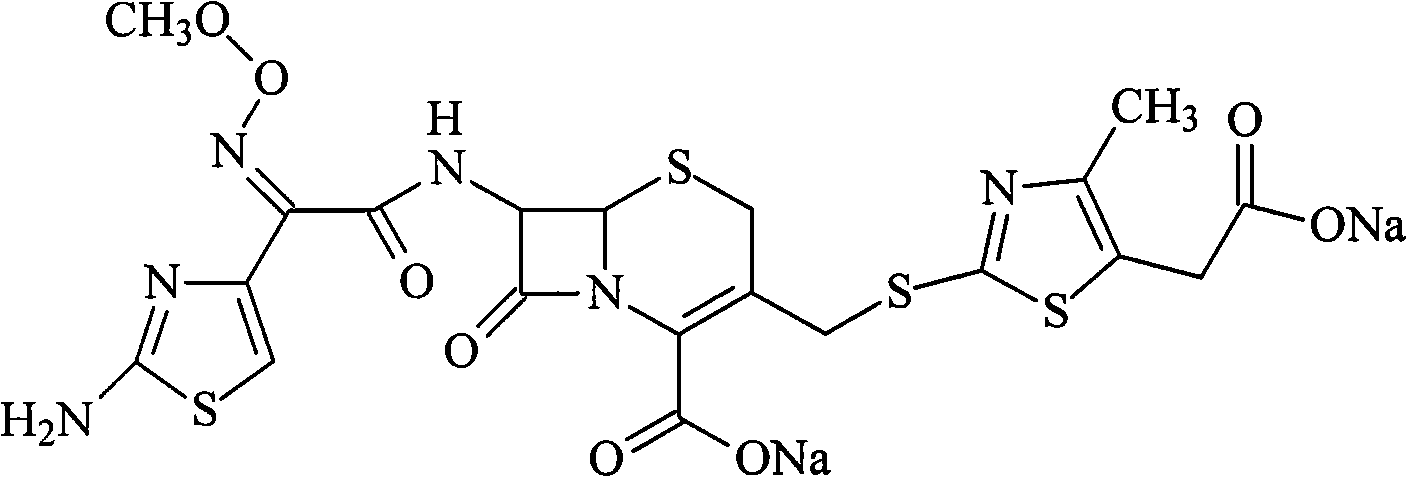

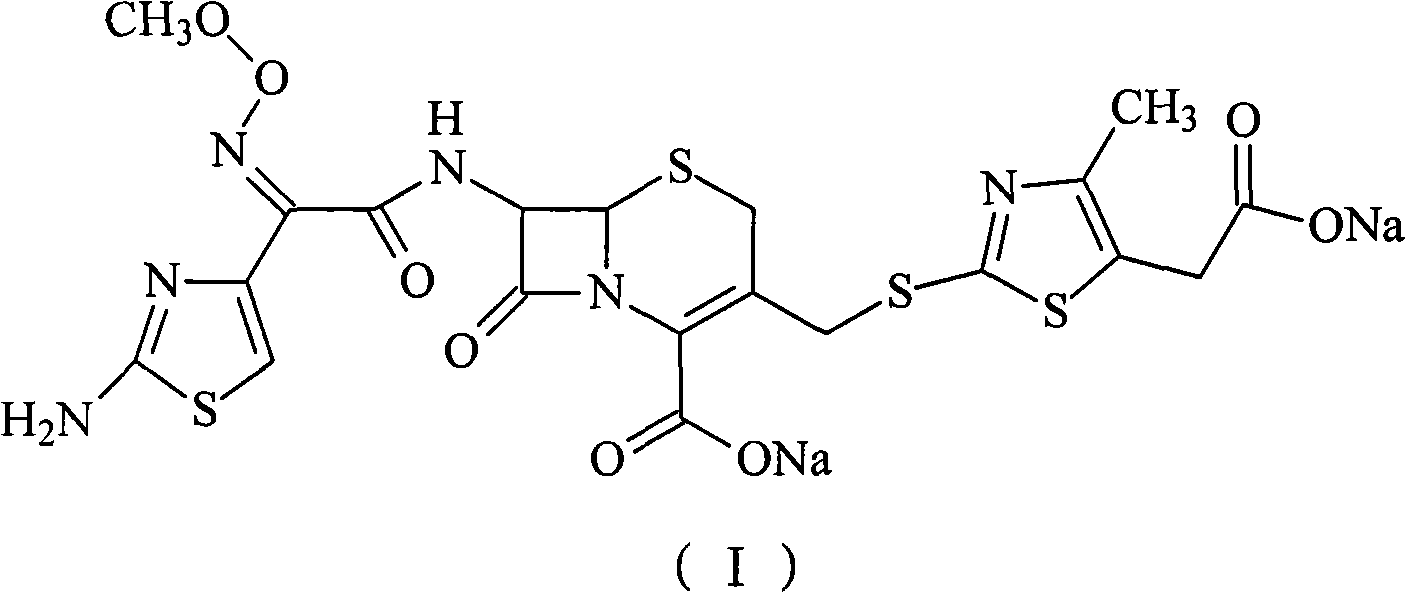

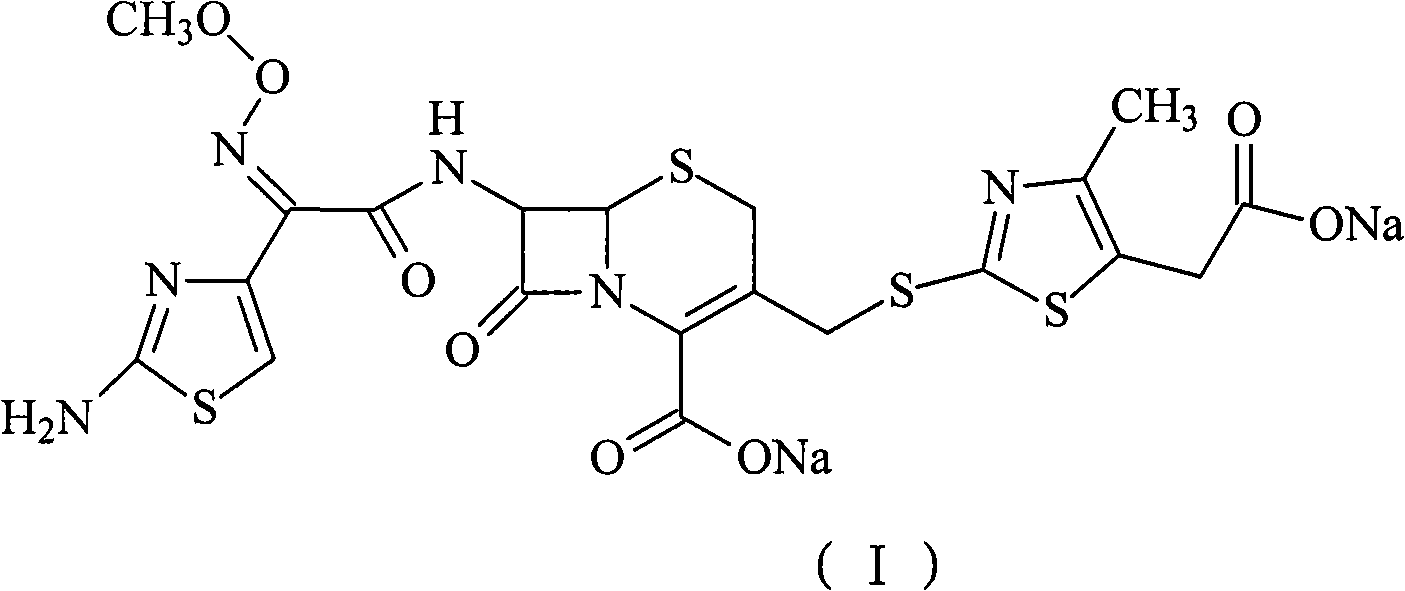

Cefodizime sodium compound and novel method thereof

A technology for cefodizime sodium and cefodizime acid, applied in the medical field, can solve problems such as improper production process control, unsatisfactory drug purity and the like, and achieve the effects of low cost, simple and easy process, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The refining of embodiment 1 cefodizime sodium

[0040] (1) 100g of cefodizime sodium crude product with a purity of 96.7% was dissolved in 1000ml of water, then slowly added dropwise to 0.3mol / L of phosphoric acid, stirred and reacted until the pH of the solution was 2.0, and left to stand for 2h to produce cefodizime acid precipitation , Suction filtration obtains cefodizime acid 88.1g;

[0041] (2) Dissolve 88.1 g of cefodizime acid obtained in the previous step in 260 g of methanol, add 0.52 g of activated carbon, insulate at 50° C. and stir for 20 min, filter for decarburization, and collect the filtrate;

[0042] (3) the filtrate obtained in the previous step is concentrated under reduced pressure, and the preparation chromatographic column is utilized to carry out separation and purification, wherein the mobile phase used in the chromatographic column is a mixed solution of acetonitrile and pH value 9.5 in a volume ratio of 3: 1, The stationary phase filler is s...

Embodiment 2

[0043] The refining of embodiment 2 cefodizime sodium

[0044] (1) the cefodizime sodium crude product that 100g purity is 96.7% is dissolved in 1000ml water, then slowly add the hydrochloric acid of 0.1mol / L, the pH of stirring reaction to solution is 2.5, leaves standstill 1h, produces cefodizime acid precipitation, Suction filtration obtains cefodizime acid 88.9g;

[0045] (2) Dissolve 88.9 g of cefodizime acid obtained in the previous step in 690 g of acetonitrile, add 2.8 g of activated carbon, insulate at 40° C. and stir for 30 min, filter for decarburization, and collect the filtrate;

[0046] (3) The filtrate obtained in the previous step is concentrated under reduced pressure, and the preparation chromatographic column is utilized to carry out separation and purification, wherein the mobile phase used in the chromatographic column is a mixed solution of acetonitrile and pH value 10.5 sodium hydroxide solution with a volume ratio of 3: 1, fixed The phase filler is sel...

Embodiment 3

[0047] The refining of embodiment 3 cefodizime sodium

[0048] (1) the cefodizime sodium crude product that 100g purity is 96.7% is dissolved in 1000ml water, then slowly add the acetic acid of 1.0mol / L, the pH of stirring reaction to solution is 3.0, produces cefodizime acid precipitation, suction filtration obtains cephalosporin Dizinic acid 89.3g;

[0049] (2) Dissolve 89.3g of cefodizime acid obtained in the previous step in 450g of chloroform, add 1.8g of gac, insulate at 50°C and stir for 20min, filter for decarburization, and collect the filtrate;

[0050] (3) the filtrate obtained in the previous step is concentrated under reduced pressure, and the preparation chromatographic column is utilized to carry out separation and purification, wherein the mobile phase used in the chromatographic column is a mixed solution of acetonitrile and pH value 11 in a volume ratio of 3: 1, The stationary phase filler is selected from silica gel, the flow rate is 4.0ml / min, and the colu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com