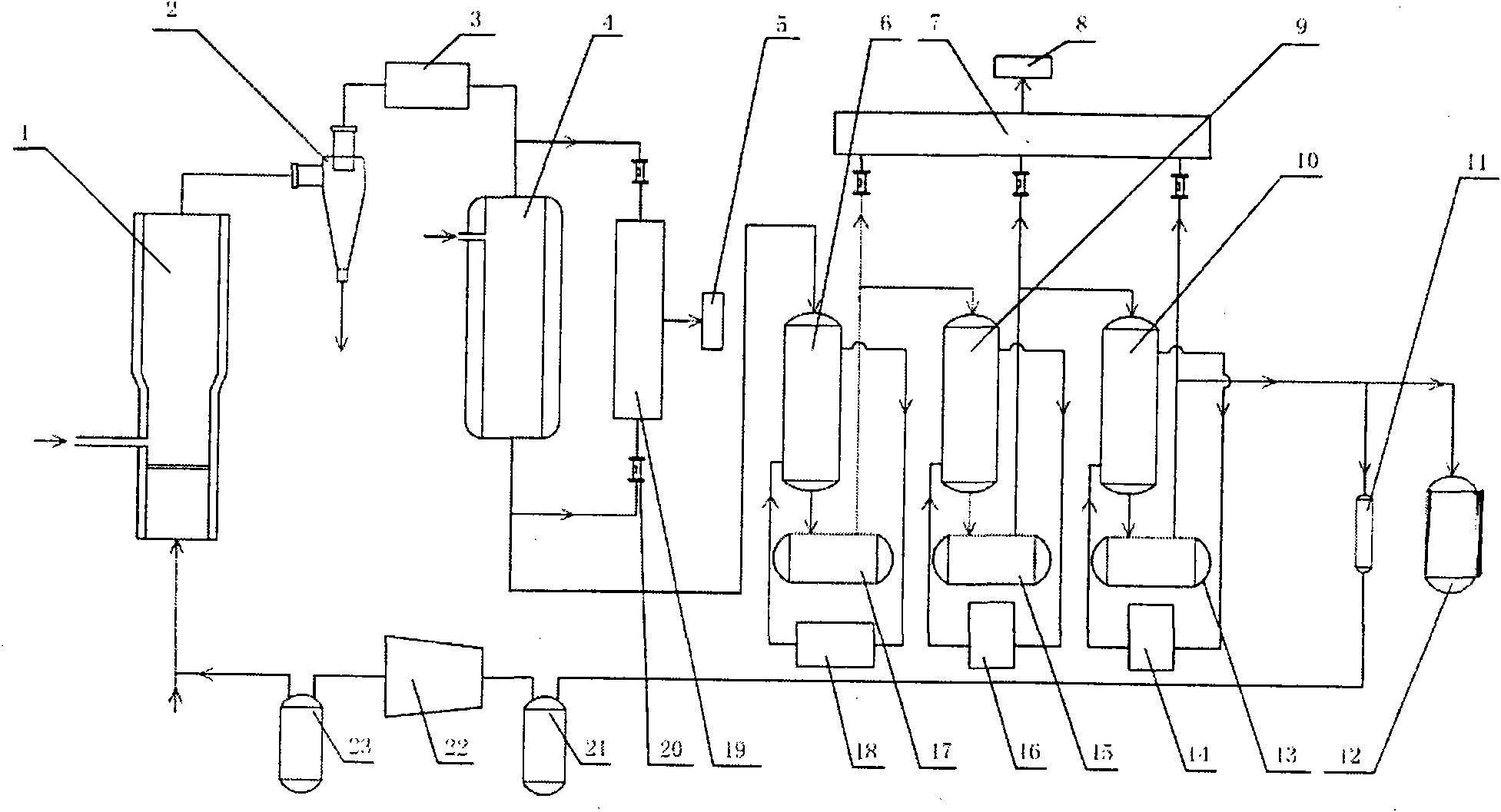

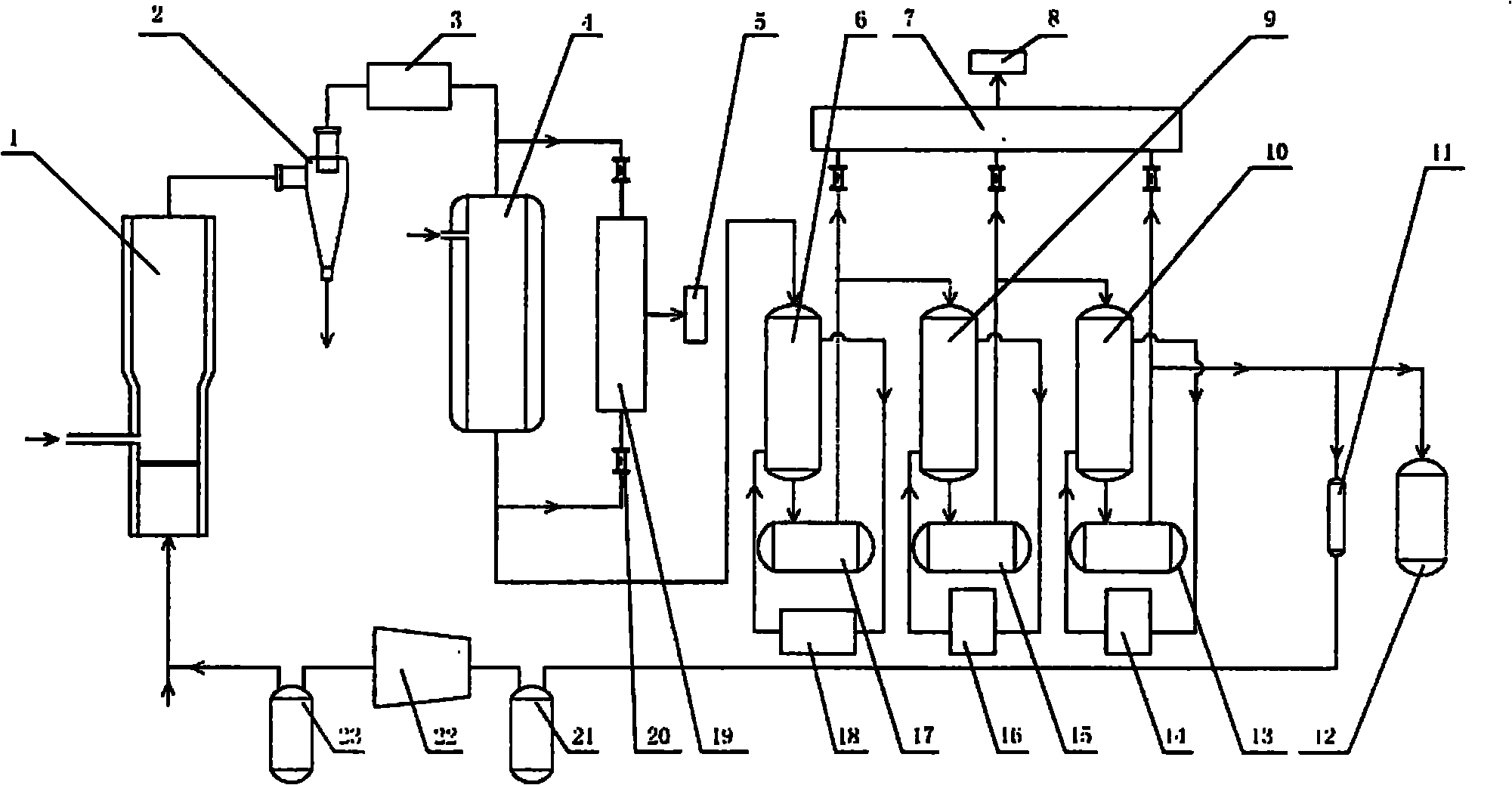

Regulation and control testing device for preparation of bio-oil through quick thermal cracking of biomass

A thermal cracking and bio-oil technology, which is applied in the preparation of liquid hydrocarbon mixtures, biofuels, petroleum industry, etc., can solve the problems of high cost, unsatisfactory industrial application, and poor quality of bio-oil, etc., to overcome insufficient condensation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The on-line regulation device of biomass rapid pyrolysis bio-oil with a processing capacity of 1kg / h is used to process larch sawdust to study the orientation and on-line regulation of bio-oil, and the fixed bed is filled with SBA-15 mesoporous molecular sieves.

[0065] Its concrete technological operation is as follows:

[0066] Adjust the heating furnace, set the temperature in the fluidized bed pyrolysis reactor to 550°C, the temperature in the fixed bed pyrolysis reactor to 450°C, the bed material in the fluidized bed is quartz sand, and fill the fixed bed with 30ml of SBA-15 Porous molecular sieve catalyst. Turn on the circulating fan and adjust the circulating air volume in the pipeline to 6m 3 / h, open the valve in the connecting pipeline, and run the fluidizing gas circulation system. Open the circulating baths of the condensers at all levels, set the condensation temperature at each level, and run the condensation system. After the fluidized bed pyrolysis r...

Embodiment 2

[0068] The on-line regulation device of biomass rapid pyrolysis bio-oil with a processing capacity of 1kg / h is used to process larch sawdust,

[0069] To study the directional and on-line regulation of bio-oil, the fixed bed is filled with HZSM-5 microporous molecular sieve.

[0070] Its concrete technological operation is as follows:

[0071] Adjust the heating furnace, set the temperature in the fluidized bed pyrolysis reactor to 550°C, the temperature in the fixed bed pyrolysis reactor to 450°C, the bed material in the fluidized bed is quartz sand, and the fixed bed is filled with 30ml of HZSM-5 micro Porous molecular sieve catalyst. Turn on the circulating fan and adjust the circulating air volume in the pipeline to 6m 3 / h, open the valve in the connecting pipeline, and run the fluidizing gas circulation system. Open the circulating baths of the condensers at all levels, set the condensation temperature at each level, and run the condensation system. After the fluidize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com