Chemical plating method for preparing ultrathin palladium film with high specific surface area

An electroless plating and palladium film technology, which is applied in the field of electroless plating of ultra-thin palladium-based composite films, can solve the problems of difficult control of etching process corrosion thickness, affecting bonding strength, cumbersome process, etc., and achieve enhanced hydrogen permeability and surface activity , reduce waste of resources, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

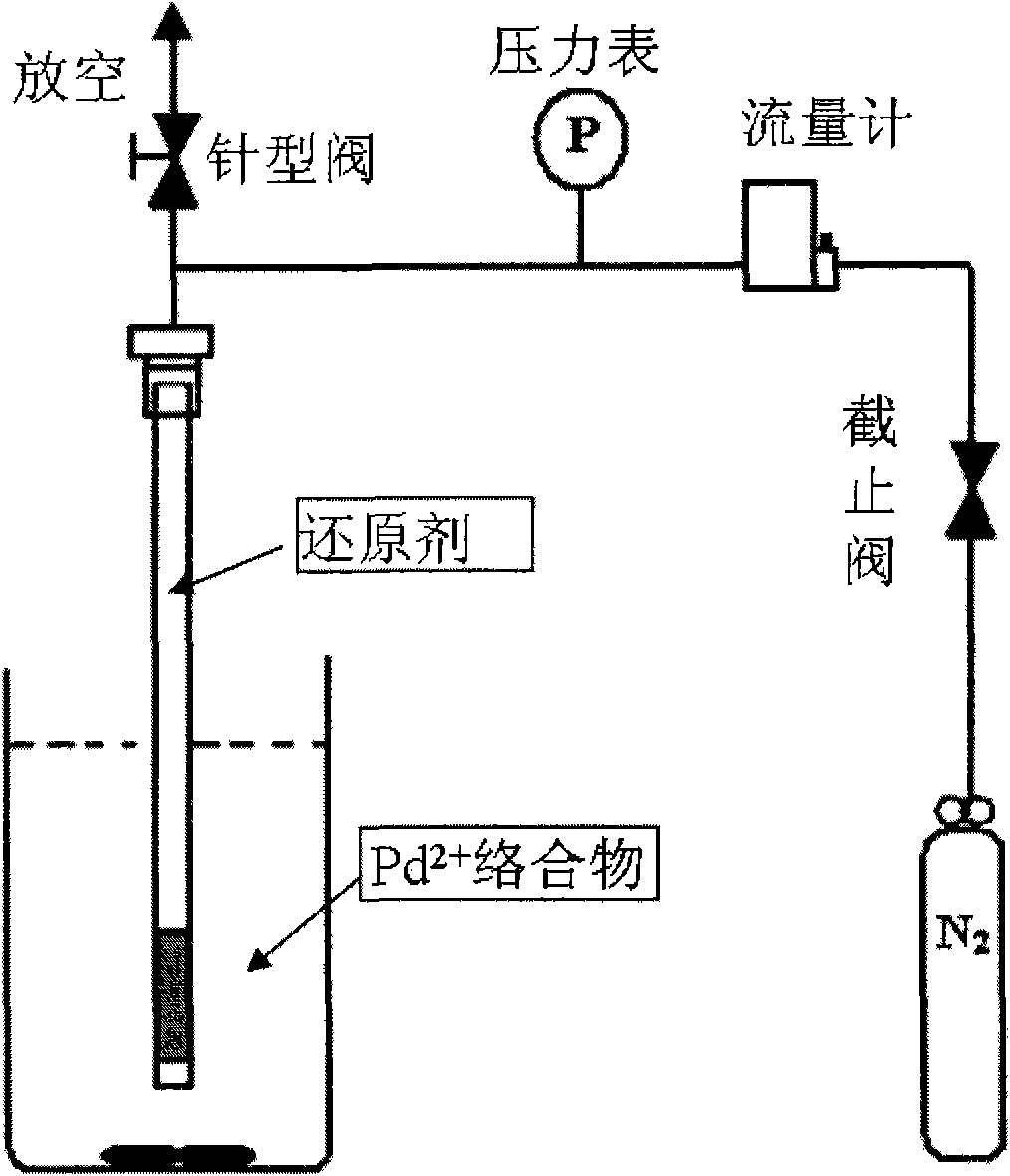

[0019] Preparation of palladium / ceramic composite membrane (inert gas driven reducing agent)

[0020] 1. Plating solution preparation

[0021] 1) Preparation of palladium metal complex solution. Weigh 1.86g disodium edetate and dissolve it in 100ml water, then measure PdCl separately 2 Solution (20g Pd / l) 25ml, NH 3 h 2 O (28%) 120ml was poured into the beaker of EDTA aqueous solution successively, diluted to 500ml, pH value 11-12, stirred gently for 1 hour (h).

[0022] 2) Preparation of reducing agent solution. Dilute hydrazine hydrate to 0.65mol / l for later use.

[0023] 2. Electroless plating

[0024] 1) Activate the seed nucleus. The ceramic carrier was successively immersed in the dilute solution of the activation solution OPC-50Inducer and the reducing agent OPC-150Cryster MU (Okuno Chemical Industry Co., Ltd., Japan) to activate the seed nucleus, and circulated until the surface became uniform dark gray. In order to make the distribution of palladium nuclei on ...

Embodiment 2

[0031] Preparation of palladium / ceramic composite membrane (osmotic pressure driven reducing agent)

[0032] 1. Plating solution preparation

[0033] Do not add EDTA in the plating solution, add NaCl 88g, other with example 1.

[0034] 2. Electroless plating

[0035] 1) Activate the seed nucleus. With embodiment 1.

[0036] 2) Chemical spot plating. Dip the pre-plated ceramic tube in the plating solution, the plating solution is weakly stirred, and the plating temperature is 50°C. Take diluted N 2 h 4 10ml of aqueous solution (0.65mol / l) was injected into the ceramic tube, and removed after electroless plating for 3 hours.

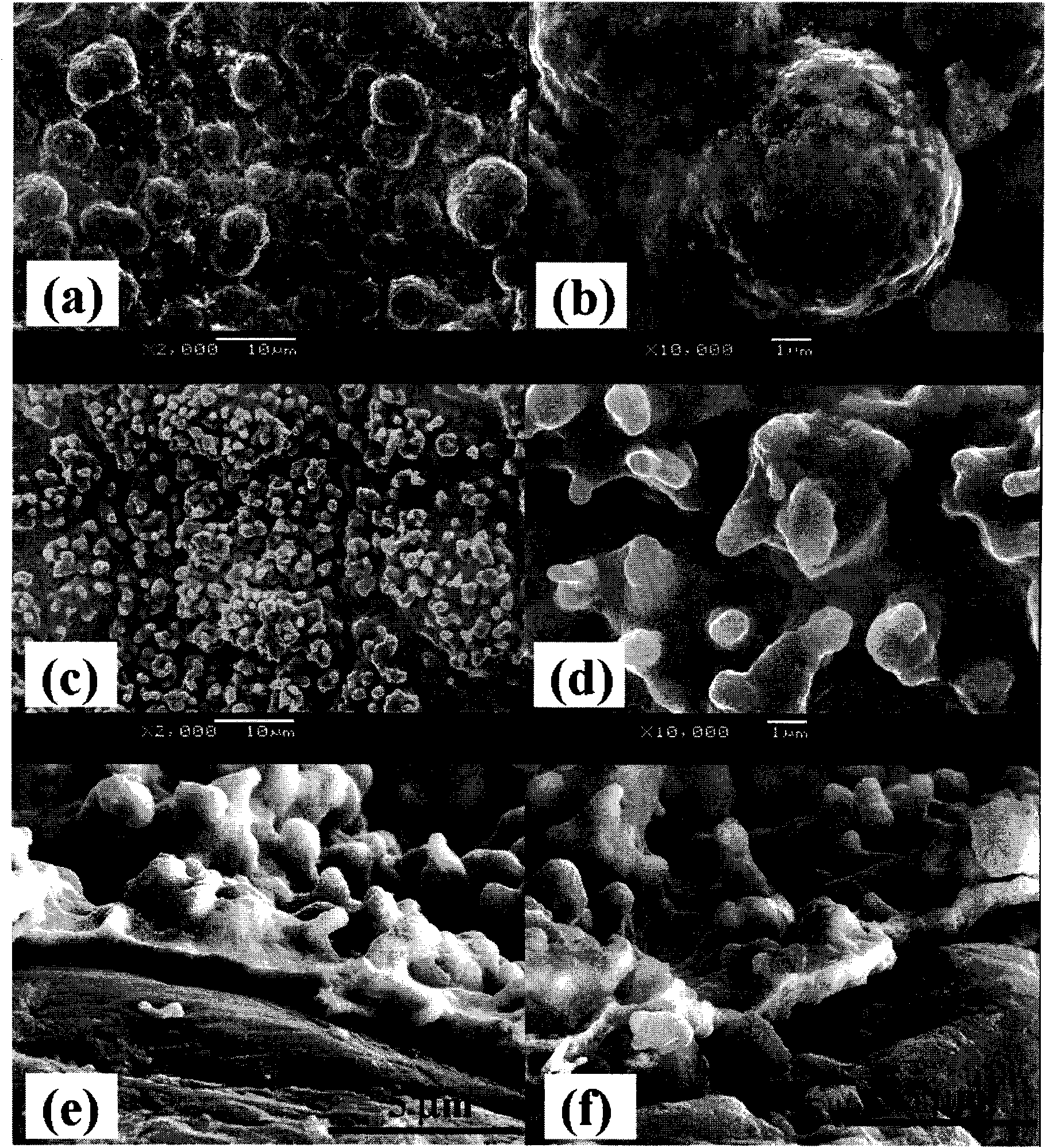

[0037] After the electroless plating is completed, after cleaning and drying, the palladium ceramic composite membrane is annealed at 500° C. under a hydrogen atmosphere for 40 hours. By the weight difference before and after electroless plating, the average film thickness of the obtained palladium film is 1.8 μm. According to the characterization ...

Embodiment 3

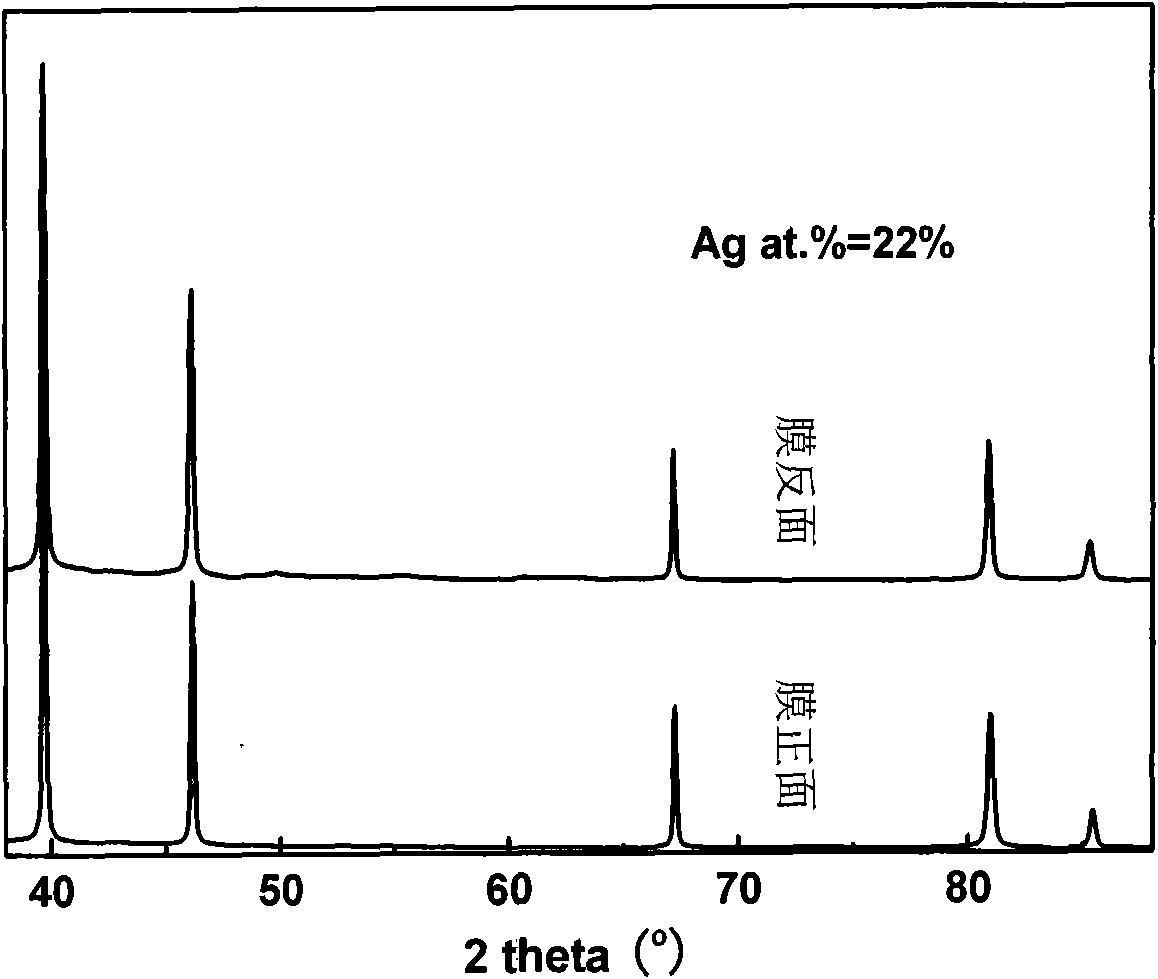

[0041] Preparation of Pd-Ag / Ceramic Composite Membrane

[0042] 1. Plating solution preparation

[0043] 1) Preparation of palladium-silver metal complex solution. Plating solution configuration is the same as that of Example 1, additionally adding AgNO 3 Solution (20g / l) 2ml.

[0044] 2) Preparation of reducing agent solution. With embodiment 1.

[0045] 2. Electroless plating

[0046] 1) Activate the seed nucleus. With embodiment 1.

[0047] 2) Chemical spot plating. The pre-plated ceramic carrier is immersed in the plating solution, the plating solution is weakly stirred, and the plating temperature is 58°C. Reductant N 2 h 4 10ml of aqueous solution was poured into the ceramic tube, and the upper end of the tube was connected to the pressurized system and sealed with polytetrafluoroethylene. After 60 minutes without loading pressure, pressurize to 2kPa, after 120 minutes, increase the pressure to 5kPa, take out after 60 minutes of reaction.

[0048] After the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com