Sterilization process and equipment of absorbable sutures

A suture and equipment technology, applied in the field of absorbable suture ethylene oxide sterilizer and technology, can solve the problems that absorbable suture cannot meet, low ethylene oxide residue, unsuitable absorbable suture, etc. , to achieve the effect of saving manpower, improving work efficiency and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

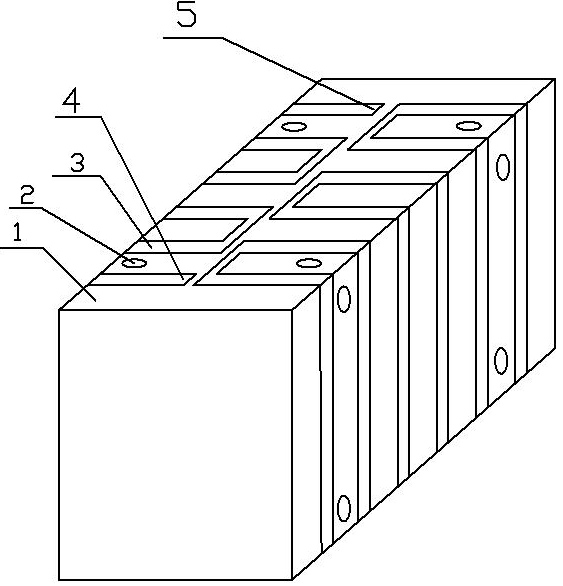

[0063] Embodiment 1: A kind of sterilized use equipment of absorbable suture (see attached Figure 6 , 7 , 8), including the control cabinet equipped with PLC (not shown in the figure), the box 9 and the heating system connected to the box 9, vacuum system, dosing system, humidification system, compressed air system, vaporization system, drying Gas injection system, a waste gas recovery box 30 connected to the outside of the vacuum system;

[0064] Wherein box body 9 comprises the cylinder body 1 that is the rectangular parallelepiped of open both ends that places horizontally (referring to attached figure 1 ), the side wall of the cylinder body 1 is a double-layer structure including inner and outer shells, the inner layer is a cuboid with openings at both ends, and the outer wall of the inner layer is provided with a plurality of ring-shaped open-loop water tanks arranged along the length direction of the box body 9 Jacket 3, the water jacket 3 is provided with a water inl...

Embodiment 2

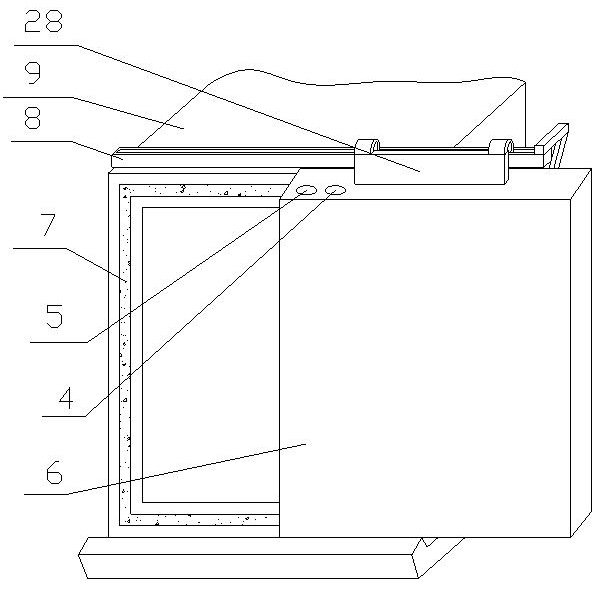

[0071] Embodiment 2: A kind of sterilized use equipment of absorbable suture (see attached Figure 7 ), its structure is basically the same as that of Embodiment 1, the difference lies in the design of the cooperation between the airtight door 6 and the cylinder body 1:

[0072] The upper end face of cylinder body 1 is fixed with the two-way air cylinder 10 that is connected with sealing door 6 upper end (see attached image 3 , 4 ), the upper end of the airtight door 6 fixes a rectangular connecting block 28, and the middle part of the connecting block 28 extends a connecting rod 29 toward the direction of the two-way cylinder 10, and the two ends of the connecting rod 29 are respectively connected to the connecting block 28 and the piston The movement of the sealing door 6 is driven by the piston movement of the two-way cylinder 10. The air holes at both ends of the two-way cylinder 10 are connected to the air compressor 24 through the pipeline 12, the electric control valv...

Embodiment 3

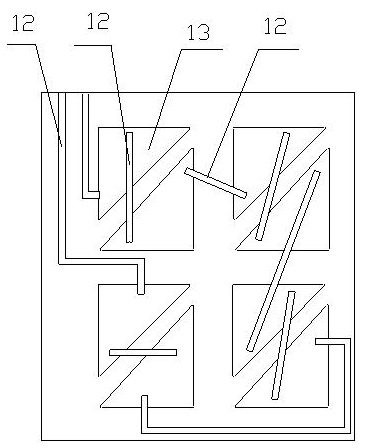

[0075] Embodiment 3: A kind of sterilized use equipment of absorbable suture (see attached Figure 6 ), its structure is basically the same as that of Embodiment 1, and its difference lies in the design of the sealed door 6:

[0076] The airtight door 6 is a double-layer structure, and the inner layer is a flat plate. Eight sealing spaces 13 are arranged on the outer end surface of the flat plate. figure 2 ), the sealed space 13 is provided with a water inlet hole 4 and a water outlet hole 5, and the sealed space 13 is connected in sequence through the pipeline 12, and the water inlet hole 4 of the first sealed space 13 is connected with the hot water circulation pump of the heating system through the pipeline 12 The outlet hole 5 of 19 is connected, and the outlet hole 5 of the last sealed space 13 is connected with the hot water container 18 of heating system through pipeline 12; The outer layer is the shell that matches with inner layer plate. For strengthening the intens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com