Method for trapping CO2 by using double tube micro-reactor

A micro-reactor and reactor technology, applied in the field of CO2 capture, can solve the problems of limited treatment capacity, unsuitable for large treatment capacity, etc., and achieve the effects of large treatment capacity, reduced CO2 absorption cost, and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

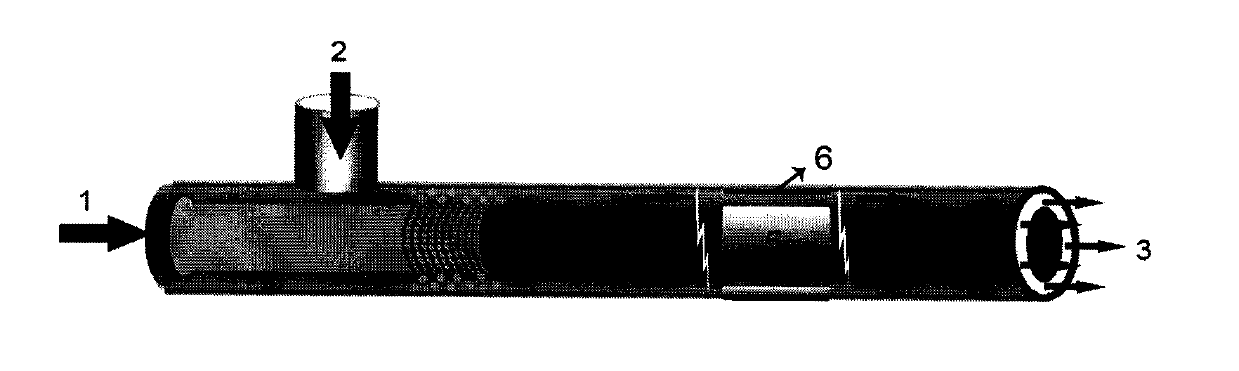

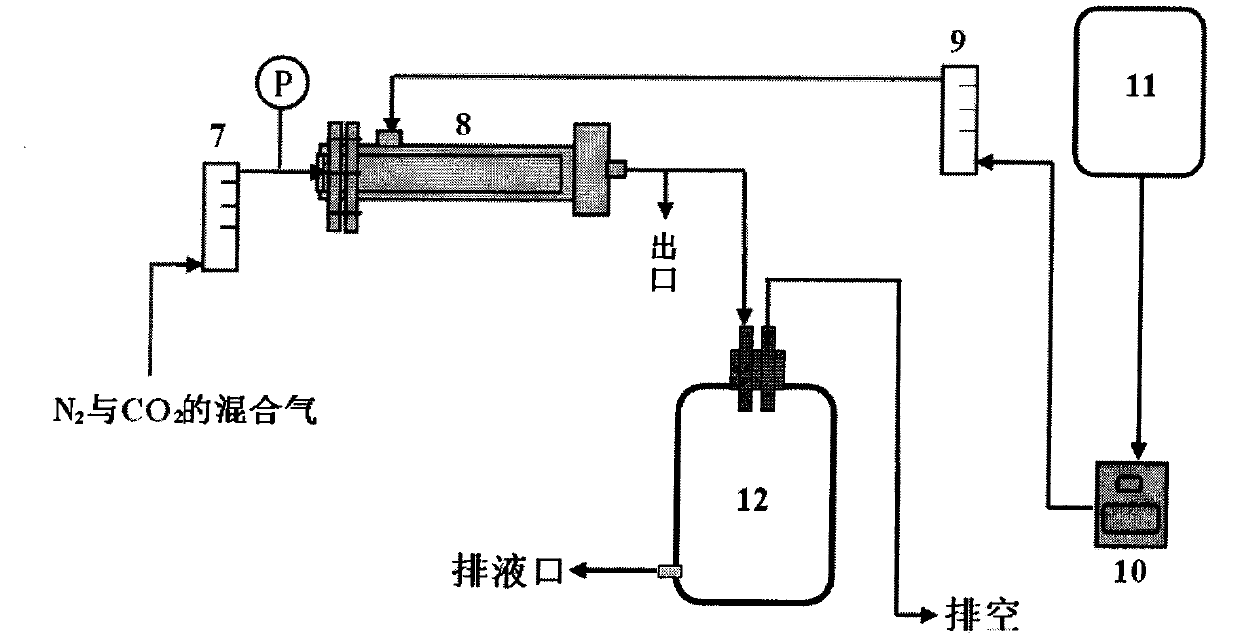

[0030] Embodiment 1: the casing type microreactor structure that adopts is as figure 1 As shown, the radial spacing of the annular microchannel is 250 μm, the diameter of the micropore is 10 μm, the length of the micropore part is 17.0 mm, and the length of the microchannel is 156.0 mm. Experimental device such as Figure 4 As shown, the N 2 with CO 2 The mixed gas (of which CO 2 content of 90%) through the gas flow meter 7, enter the inner pipe 5 from the gas inlet 1 horizontal direction at one end of the microreactor, and the pressure of the gas inlet is measured by the pressure gauge; the absorption liquid is then passed through the peristaltic pump 10, The liquid flow meter 9 is injected into the outer pipe 6 of the sleeve type microreactor from the liquid inlet 2 on the side of the microreactor 8, and the gas-liquid two-phase impacts cross-flow contact in the micropore part of the microreactor, and is in the entire annular microchannel The mass transfer process is com...

Embodiment 2

[0031] Embodiment 2: the casing microreactor and technological process that adopt are identical with embodiment 1.

[0032] Weigh 400 g of NaOH, dissolve it in deionized water to prepare 10 L of NaOH solution with a concentration of 3.8% by mass, and place it in a storage tank to seal it. The size of the sleeve-type microreactor used in this experiment is: the diameter of the micropore is 10 μm, the radial spacing of the annular microchannel is 500 μm, the length of the micropore part is 17.0 mm, and the length of the microchannel is 156.0 mm. During the experiment, the N 2 with CO 2 The mixed gas (of which CO 2 The content is 85%) through the gas flow meter into the inner tube of the horizontal sleeve type microreactor; the liquid in the liquid storage tank is injected into the outer tube of the microreactor by the peristaltic pump connected in series. The gas-liquid two-phase impact contacts in the micropore part of the microreactor, and the entire mass transfer process i...

Embodiment 3-5

[0033] Embodiment 3-5: the jacketed microreactor and technological process that adopt are identical with example 1.

[0034] Prepare the absorbent in the reservoir and seal it. During the experiment, the N 2 with CO 2 The mixed gas (of which CO 2 The content is shown in Table 1) through the gas flowmeter into the inner tube of the casing microreactor placed horizontally; the liquid in the liquid storage tank is injected into the outer tube of the microreactor by the peristaltic pump connected in series. The length of the micropore part of the sleeve-type microreactor used in the experiment is 17.0mm, and the length of the microchannel is 156.0mm. Other dimensions are shown in Table 1. The gas-liquid two-phase impact contacts in the micropore part of the microreactor, and completes the entire mass transfer process in the microchannel part. In the experiment, glass thermometers were used to measure the temperature of gas, liquid and gas-liquid phase separation bottle respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com