Reactor for producing phenyl chlorosilane by using thermal poly-condensation method

A phenylchlorosilane and reactor technology, which is applied in the field of reactors for preparing phenylchlorosilane, can solve the problems of carbon deposition in the bed, low production efficiency, complicated by-product magnesium chloride and solvent treatment, etc., so as to avoid damage and reaction smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

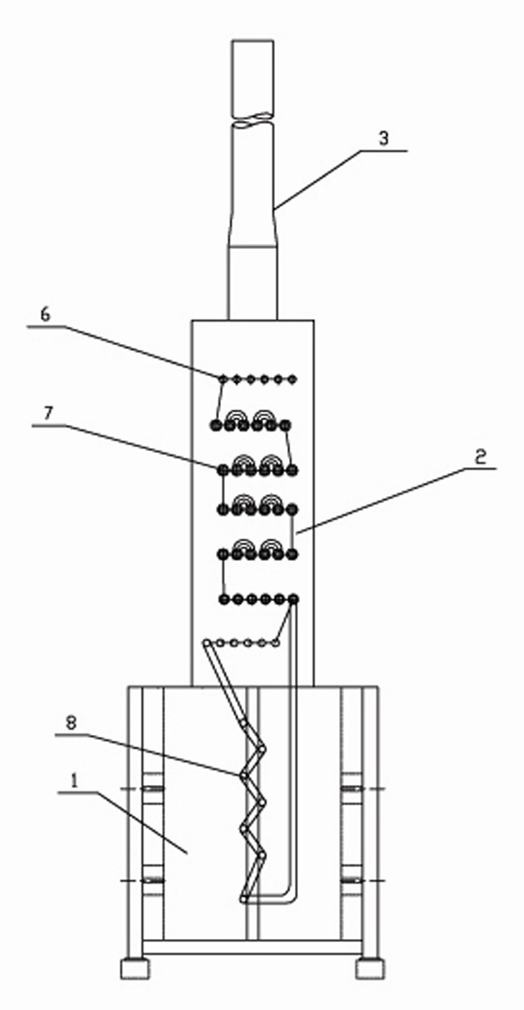

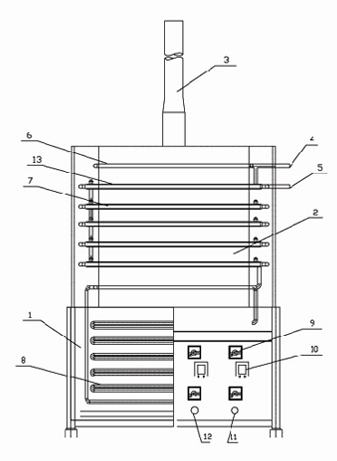

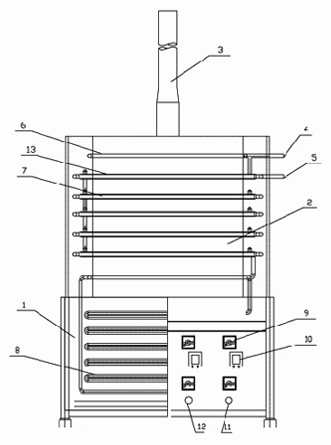

[0023] As shown in the figure, the reactor for producing phenylchlorosilane by thermal condensation method of the present invention includes the reactor body. The reactor body is provided with a radiation zone 1 (ie heating section) at the lower part of the body and a convection zone 2 (ie reaction section) at the middle of the body. A chimney 3 is also arranged on the upper part of the reactor body. The heating section furnace tube 8 is arranged in the radiation area 1, and the entire radiation area 1 is in a rectangular shape as a whole. In actual use, it can be designed as the following dimensions according to the needs: length: 6000mm, width: 4000mm, height: 4000mm or length: 7500mm, Width: 5000mm, height: 5000mm or length: 9000mm, width: 6000mm, height: 6000mm. Due to the design of the above dimensions, the heat radiation space of the radiation zone 1 is more suitable and the radiation effect is better. There are also flameless burners 9 and flame observation holes 10 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com