Method for preparing photochemical catalyst applied to degradation of environmental pollutants by using solar energy

A technology for environmental pollutants and photocatalysts, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of narrow spectral response range, wide band gap, etc. The effect of broadening the absorption wavelength and improving the photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

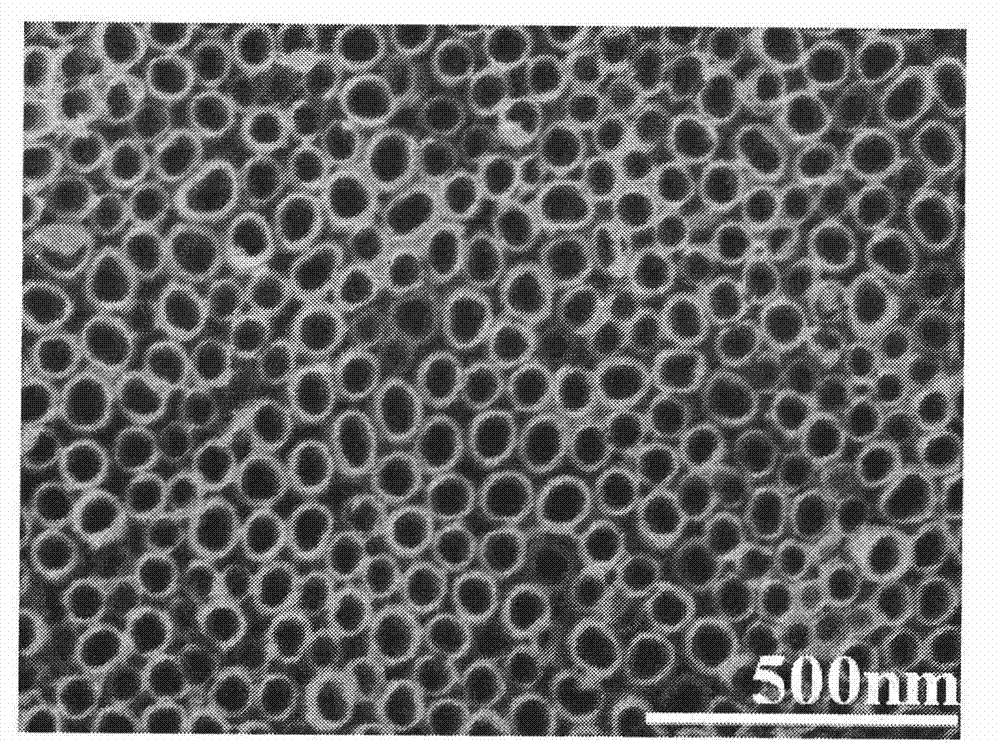

[0032] Prepare 0.05mol / L CdCl 2 and 0.05mol / L Na 2 S precursor solution, to which trisiloxane surfactant was added. Using the vacuum infusion method, TiO with a diameter of 60 nm and a thickness of 5 μm 2 Nanotubes filled with 0.05mol / L CdCl 2 and 0.05mol / L Na 2 S precursor solution, after repeating 3 times, the nanotubes were immersed in the two solutions respectively, and the immersion time was 30s each time. After each removal, the surface solution was wiped dry, and the process was repeated 15 times.

[0033] Prepare 0.2mol / L Zn(NO 3 ) 2 , hexamethylenetetramine aqueous solution, mixed uniformly by volume 1:1, as the precursor solution. with TiO 2 -NT S / CdS as the substrate, placed in a reaction kettle, added 20mL of precursor solution, and reacted in an oven at 90°C for 4h.

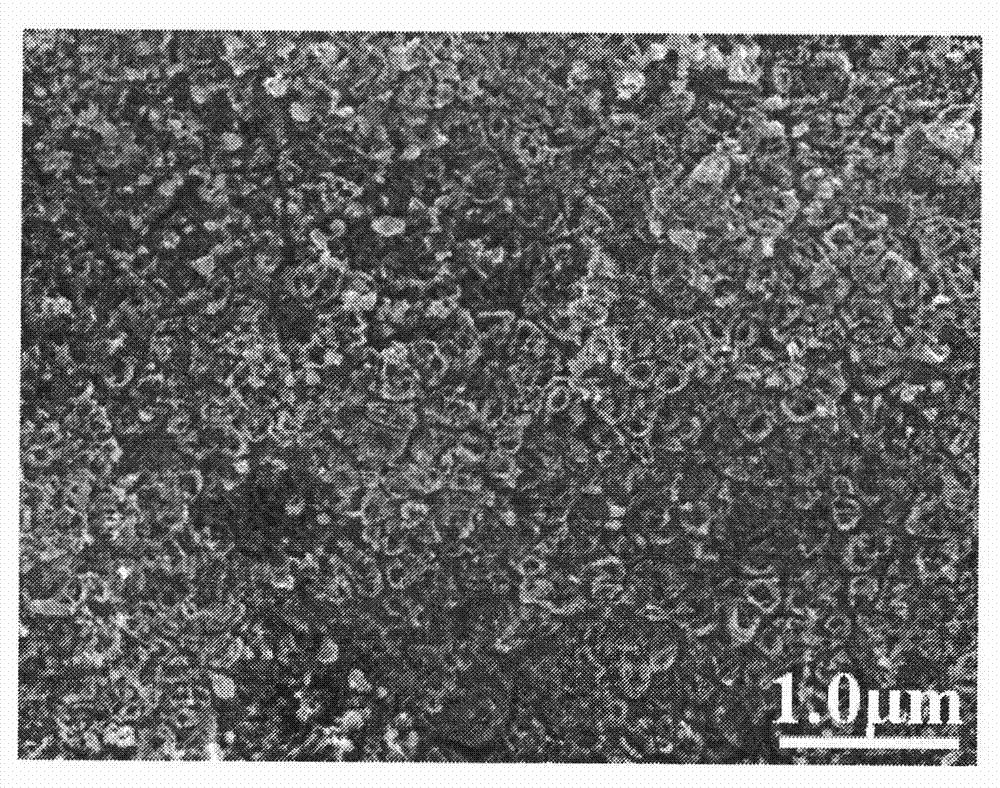

[0034] figure 1 and figure 2 Be respectively the TiO selected in embodiment 1 2 Nanotube carrier and the TiO prepared according to the conditions of Example 1 2 -NT S / CdS photocataly...

Embodiment 2

[0036] Prepare 0.05mol / L CdCl 2 and 0.05mol / L Na 2 S precursor solution, to which trisiloxane surfactant was added. Using the vacuum infusion method, TiO with a diameter of 60 nm and a thickness of 5 μm 2 Nanotubes filled with 0.05mol / L CdCl 2 and 0.05mol / L Na 2 S precursor solution, after repeating 3 times, the nanotubes were immersed in the two solutions respectively, and the immersion time was 30s each time. After each removal, the surface solution was wiped dry, and the process was repeated 15 times.

[0037] Prepare 0.01mol / L Zn(NO 3 ) 2 , hexamethylenetetramine aqueous solution, mixed uniformly by volume 1:1, as the precursor solution. with TiO 2 -NT S / CdS as the substrate, placed in a reaction kettle, added 20mL of precursor solution, and reacted in an oven at 90°C for 6h.

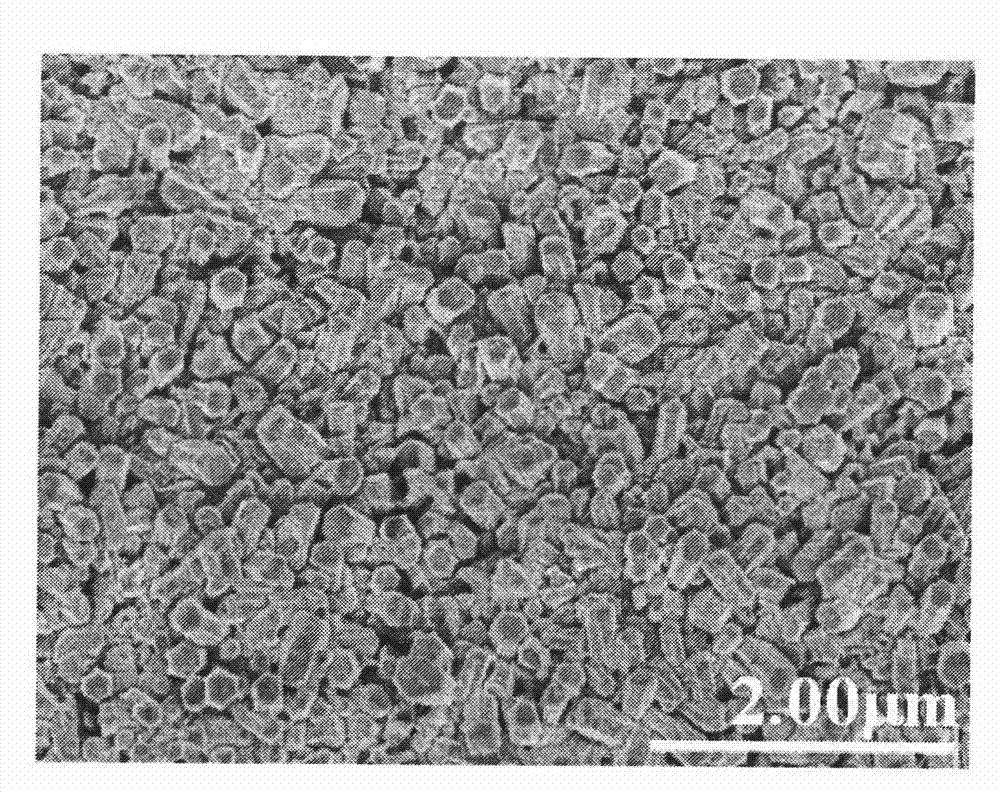

[0038] Figure 4 It is the TiO prepared according to the conditions and conditions of Example 2 2 -NT S / CdS-ZnO photocatalyst morphology. Such as Figure 4 As shown, when the precurs...

Embodiment 3

[0041] A method for preparing a photocatalyst applied to solar energy degradation of environmental pollutants, the method is based on TiO 2 Nanotubes are used as the carrier, and CdS is used as the sensitizer to broaden the absorption band of the photocatalyst in the visible region. On TiO 2 -NT S / CdS surface constructs ZnO nanorods as a protective layer to prevent the photocorrosion of CdS, improve the stability and photocatalytic activity, and finally obtain TiO 2 -NT S / CdS-ZnO microstructure and can be applied to photocatalysts for solar degradation of environmental pollutants.

[0042] Described method specifically comprises the following steps:

[0043] (1) Prepare CdCl separately 2 and Na 2 S precursor aqueous solution, so that the concentration is 0.01mol / L, and add 0.5% surfactant trisiloxane of the total volume of the solution (please supplement the amount);

[0044] (2) with TiO 2 Nanotubes as support, TiO 2 The diameter of the nanotube is 50nm, the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com