Method for extracting refined tea saponin from camellia oleifera seed cake

A technology for tea saponin and camellia seed cake, which is applied in chemical instruments and methods, preparation of sugar derivatives, steroids, etc., can solve the defects of process, purity, yield or cost, restrict the application of tea saponin, and cause eye damage. major problems, to achieve the effect of low cost, low production cost and good physical and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

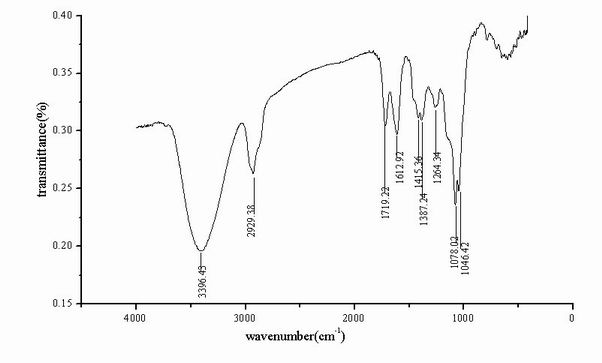

Embodiment 1

[0036] Weigh 190 g of pulverized camellia seed cake, extract with 950 mL of 85% ethanol under reflux, and extract continuously for 2 times, each time for 3 hours. The extracts were combined, concentrated under reduced pressure, ethanol was recovered, and the concentrated solution was diluted with water to a ratio of solid to liquid of 1:5. In a water bath at 50°C, add 55 mL of chitosan solution, stir thoroughly, and after standing for 3 hours, filter the solution with suction to remove the precipitate to obtain a transparent and clear liquid. Weigh 213g of pretreated AB~8 macroporous adsorption resin and put it into a glass column. The transparent and clear liquid is first fully absorbed by AB~8 macroporous adsorption resin, and then the impurities are eluted with 0.05% sodium hydroxide solution. Wash with ion water until the effluent is neutral. Then elute with 70% ethanol until no tea saponin is detected in the effluent, and this part of the eluate is collected. Add hydrog...

Embodiment 2

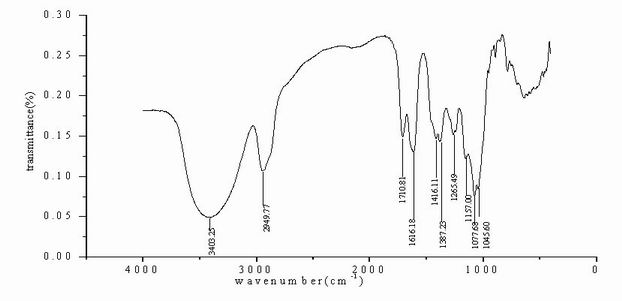

[0038] Weigh 200 g of pulverized Camellia oleifera seed cake, extract with 1200 mL of 85% ethanol under reflux, and extract continuously for 2 times, each time for 2.5 hours. The extracts were combined, concentrated under reduced pressure, ethanol was recovered, and the concentrated solution was diluted with water to a ratio of solid to liquid of 1:6. In a water bath at 60°C, add 55mL of chitosan solution, stir well, let stand for 2 hours, filter the solution with suction, remove the precipitate, and obtain a transparent and clear liquid. Weigh 214g of pretreated AB~8 macroporous adsorption resin and put it into a glass column. The transparent and clear liquid is first fully absorbed by AB~8 macroporous adsorption resin, and then the impurities are eluted with 0.2% sodium hydroxide solution. Wash with ion water until the effluent is neutral. Then elute with 70% ethanol until no tea saponin is detected in the effluent, and this part of the eluate is collected. Add hydrogen pe...

Embodiment 3

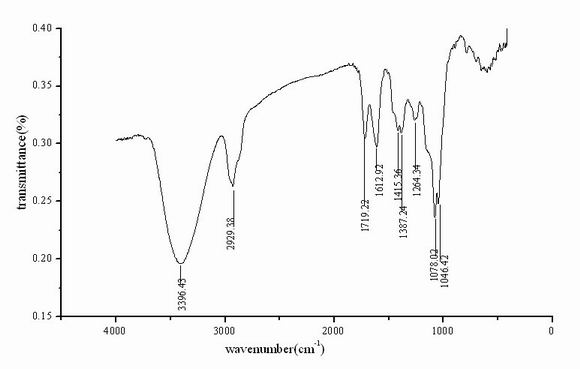

[0040] Weigh 200 g of pulverized Camellia oleifera seed cake, extract with 800 mL of 85% ethanol under reflux, and extract continuously for 3 times, each time for 2 hours. The extracts were combined, concentrated under reduced pressure, ethanol was recovered, and the concentrated solution was diluted with water to a ratio of solid to liquid of 1:5. In a water bath at 50°C, 60 mL of chitosan solution was added, fully stirred, and allowed to stand for 2.5 hours, and the solution was suction-filtered to remove precipitates to obtain a transparent and clear liquid. Weigh 213g of pretreated AB~8 macroporous adsorption resin and put it into a glass column. The transparent and clear liquid is first fully absorbed by AB~8 macroporous adsorption resin, and then the impurities are eluted with 0.05% sodium hydroxide solution. Wash with ion water until the effluent is neutral. Then elute with 80% ethanol until no tea saponin is detected in the effluent, and this part of the eluate is col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com