Application of epoxy functionalized acrylic ester polymer

An acrylate and epoxy-functional technology, which is applied in the application field of epoxy-functionalized acrylate polymers, can solve the problems of high hazard, difficulty in obtaining, and long preparation route, and achieve low toxicity and increased compatibility , the effect of increasing the molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

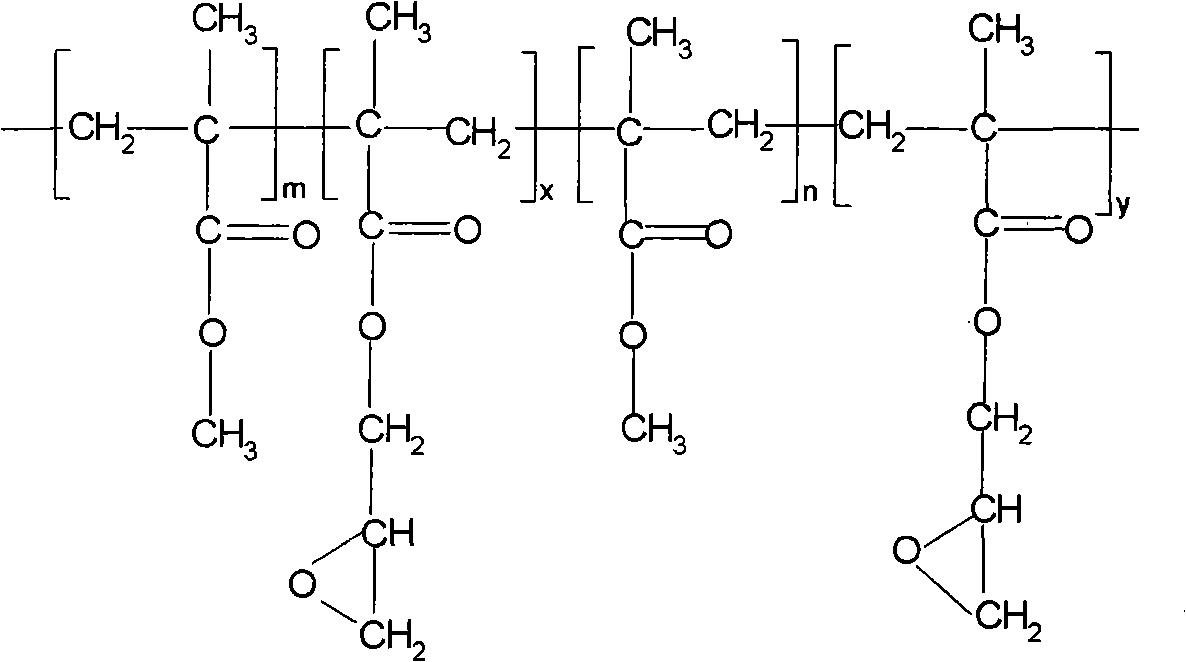

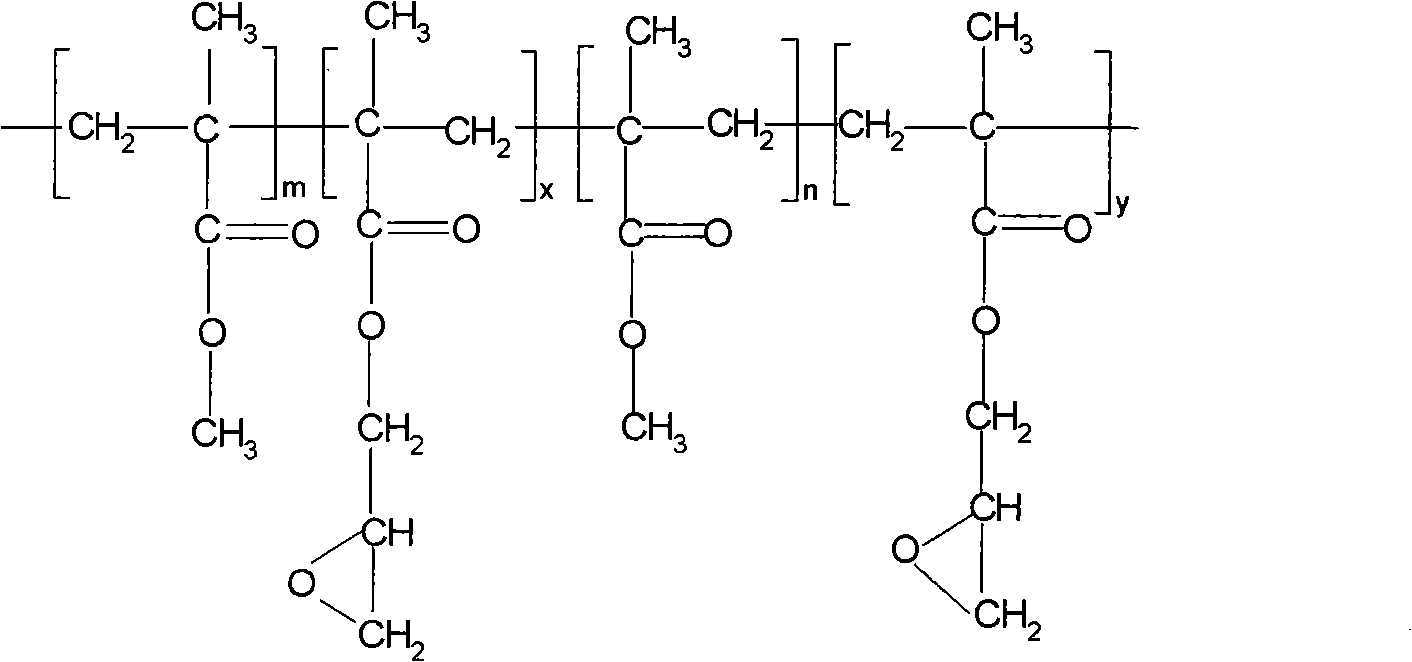

Method used

Image

Examples

Embodiment 1

[0046] 1) Preparation of an epoxy-functionalized acrylate polymer:

[0047] components

parts by weight

30

64.4

5.6

Di-tert-butyl peroxide

0.16

n-Dodecyl Mercaptan

0.04

[0048] Batch polymerization: According to the formula, mix the raw material components evenly, mix 900 grams of toluene, 2032 grams of methyl methacrylate, 168 grams of glycidyl methacrylate, 4.8 grams of di-tert-butyl peroxide, n-dodecyl sulfide 1.2 grams of alcohol, mixed evenly and added to a 5-liter reactor, using a Milton Roy model feeding pump to add to the reactor, stirring at a stirring speed of 160r / min, using nitrogen or other inert gases to fully replace the air in the reactor , using an oil bath to heat up the temperature, the oil bath temperature is constant at 120 ° C, and after the reaction is carried out for 3 hours from the oil bath temperature rise, the mixed mater...

Embodiment 2

[0052] 1) Preparation of an epoxy-functionalized acrylate polymer:

[0053] components

parts by weight

10

88.2

1.8

Di-tert-butyl peroxide

0.04

n-Dodecyl Mercaptan

0.24

[0054] Polymerization method is with embodiment 1.

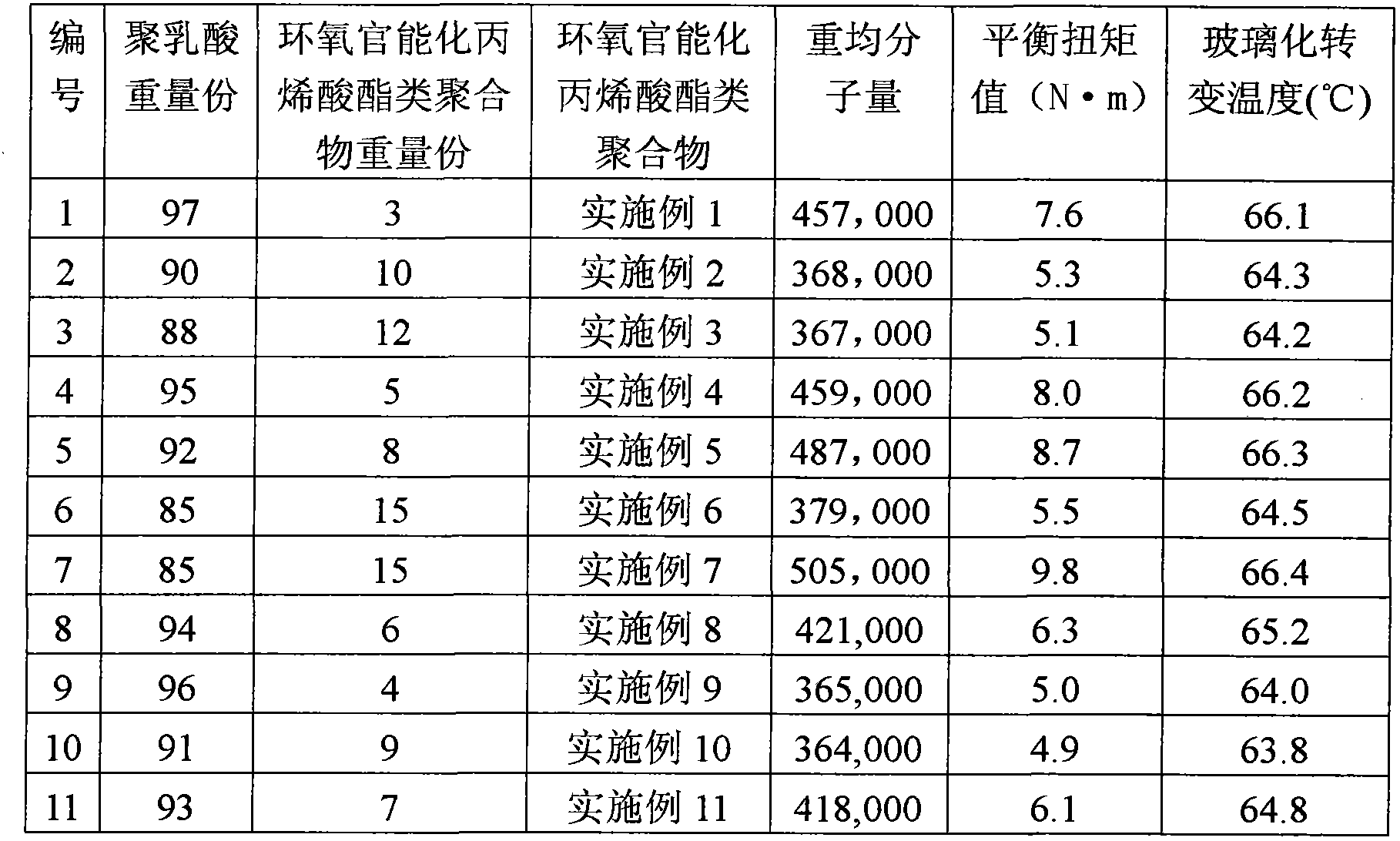

[0055] 2) Weigh 49.5g of polylactic acid and 5.5g of epoxy-functionalized acrylate polymer and melt blend them in a Haake torque rheometer. The reaction temperature is 180°C, the speed is 60r / min, and the mixing time is 10min. The measured weight-average molecular weight, equilibrium torque value, and glass transition temperature of the polylactic acid modified by chain extension are listed in Table 1.

Embodiment 3

[0057] 1) Preparation of an epoxy-functionalized acrylate polymer:

[0058] components

parts by weight

toluene

30

68.6

1.4

Di-tert-butyl peroxide

0.16

n-Dodecyl Mercaptan

0.04

[0059] Polymerization method is with embodiment 1.

[0060] 2) Weigh 48.4g of polylactic acid and 6.6g of epoxy-functionalized acrylate polymer and melt blend them in a Haake torque rheometer. The reaction temperature is 180°C, the speed is 60r / min, and the mixing time is 10min. The measured weight-average molecular weight, equilibrium torque value, and glass transition temperature of the polylactic acid modified by chain extension are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Variable temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com