High-performance aqueous epoxy anticorrosive paint for steel structures

A water-based epoxy and water-based epoxy resin technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of steel structure coating that cannot fully meet high requirements, and achieve high mechanical strength and dryness of the paint film. Fast speed and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

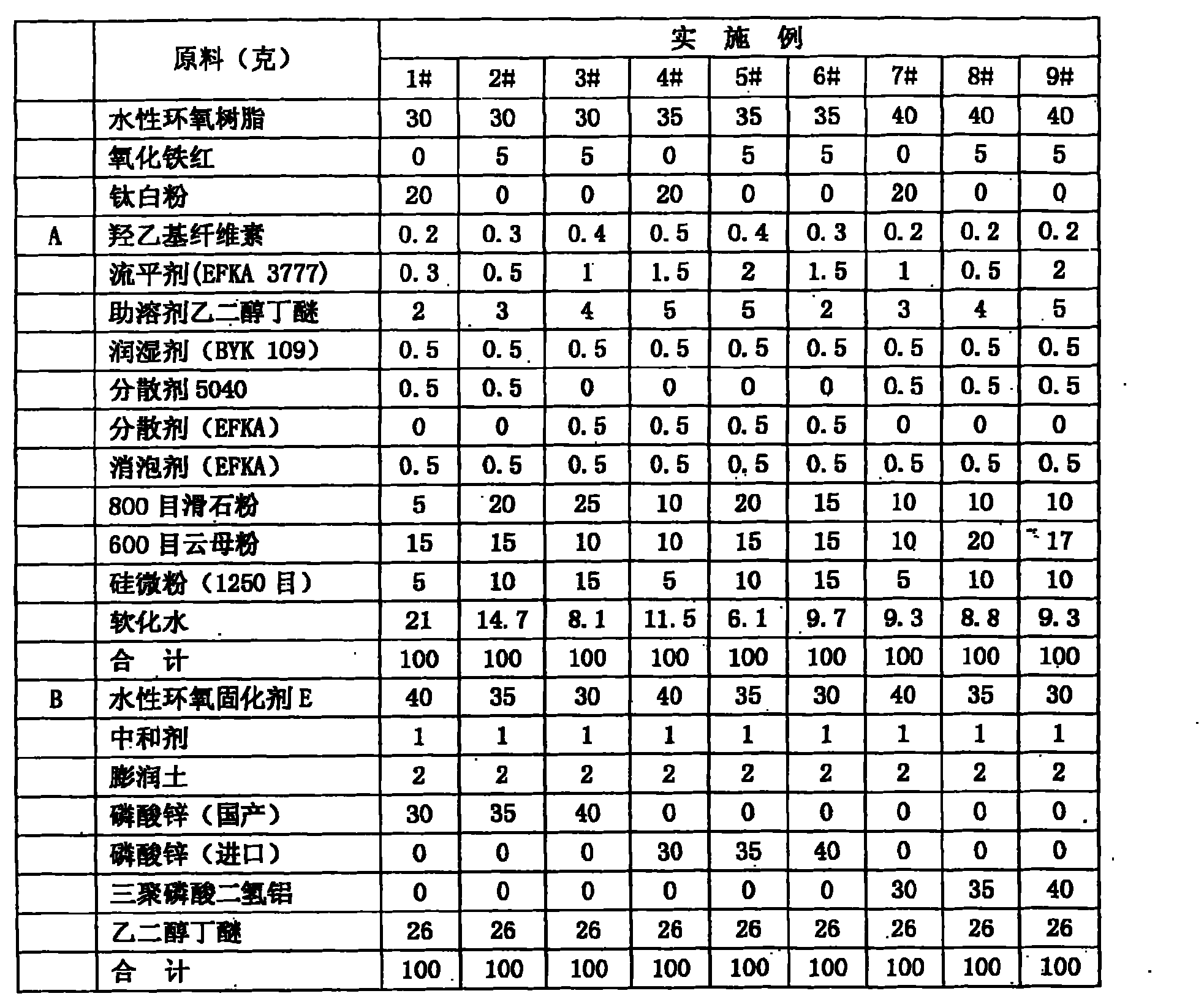

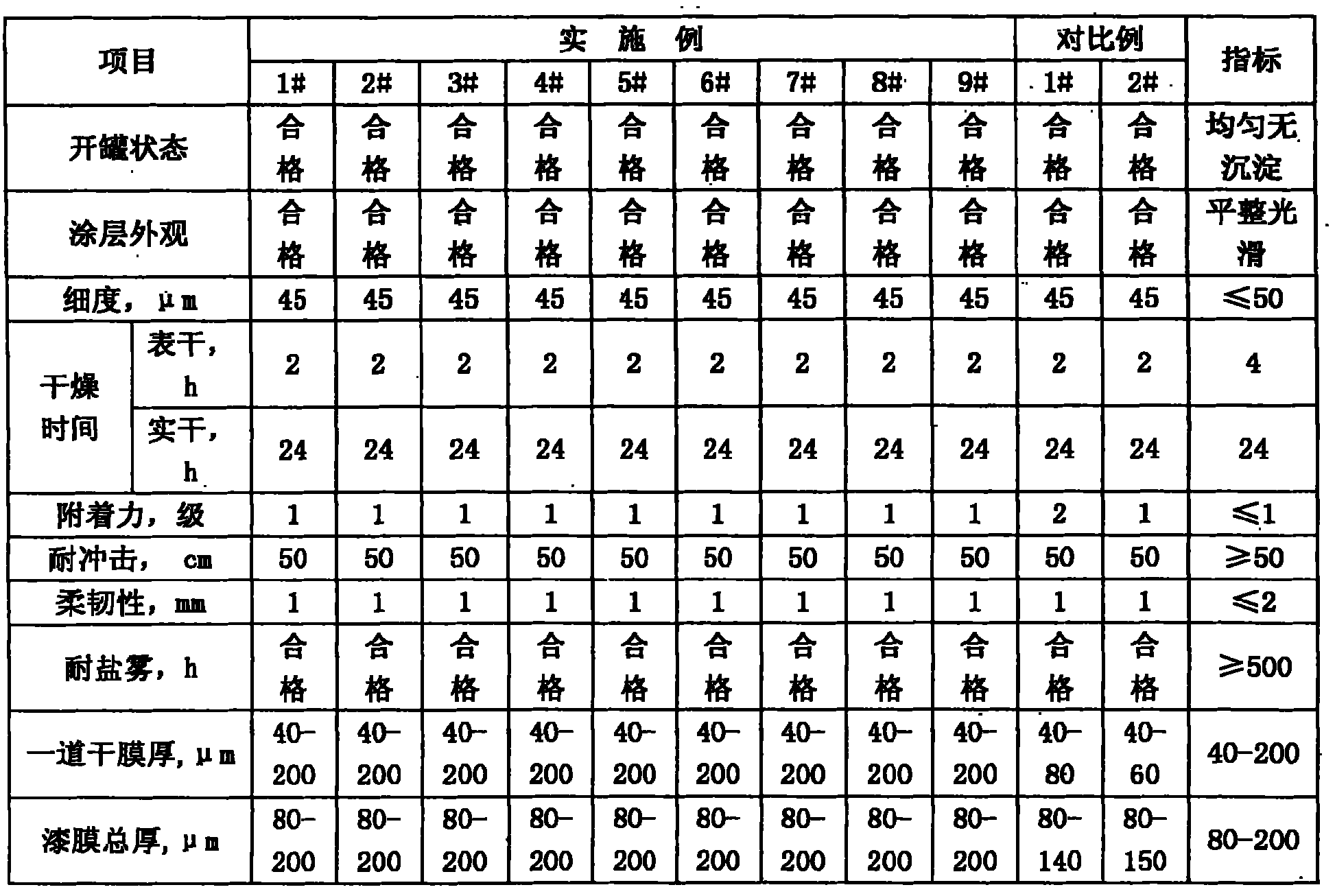

[0023] Table 1 is an example of the present invention, wherein the content of each component is in mass percentage, but the present invention is not limited to the following examples.

[0024] Table 1

[0025]

[0026] In Table 1, the aliphatic amine modified waterborne epoxy curing agent can be replaced by other modified aliphatic amine adducts with a solid content of 60wt% in equal amounts; both zinc phosphate and aluminum tripolyphosphate can be replaced by molybdic acid in equal amounts One or more mixtures of zinc, basic lead silicochromate, barium metaborate; 800-mesh talc powder, 1250-mesh silicon micropowder and 600-mesh mica powder can be replaced by light calcium carbonate and calcined kaolin in equal amounts , precipitated barium sulfate, natural barite powder, calcite powder or a mixture of one or more; titanium dioxide and iron oxide red can be replaced by one or a mixture of carbon black, phthalocyanine blue, etc. in equal amounts ; The leveling agent can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com