Preparation method of dispersing nano molybdenum disulfide in lubricating oil system

A technology of nano-molybdenum disulfide and lubricating oil, which is applied in the direction of lubricating compositions, petroleum industry, additives, etc., and can solve the problems of complex lubricating performance, organic molybdenum compound friction reduction, extreme pressure resistance, and low stability, etc., to achieve Short synthesis time, reduced synthesis cost, excellent dispersion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

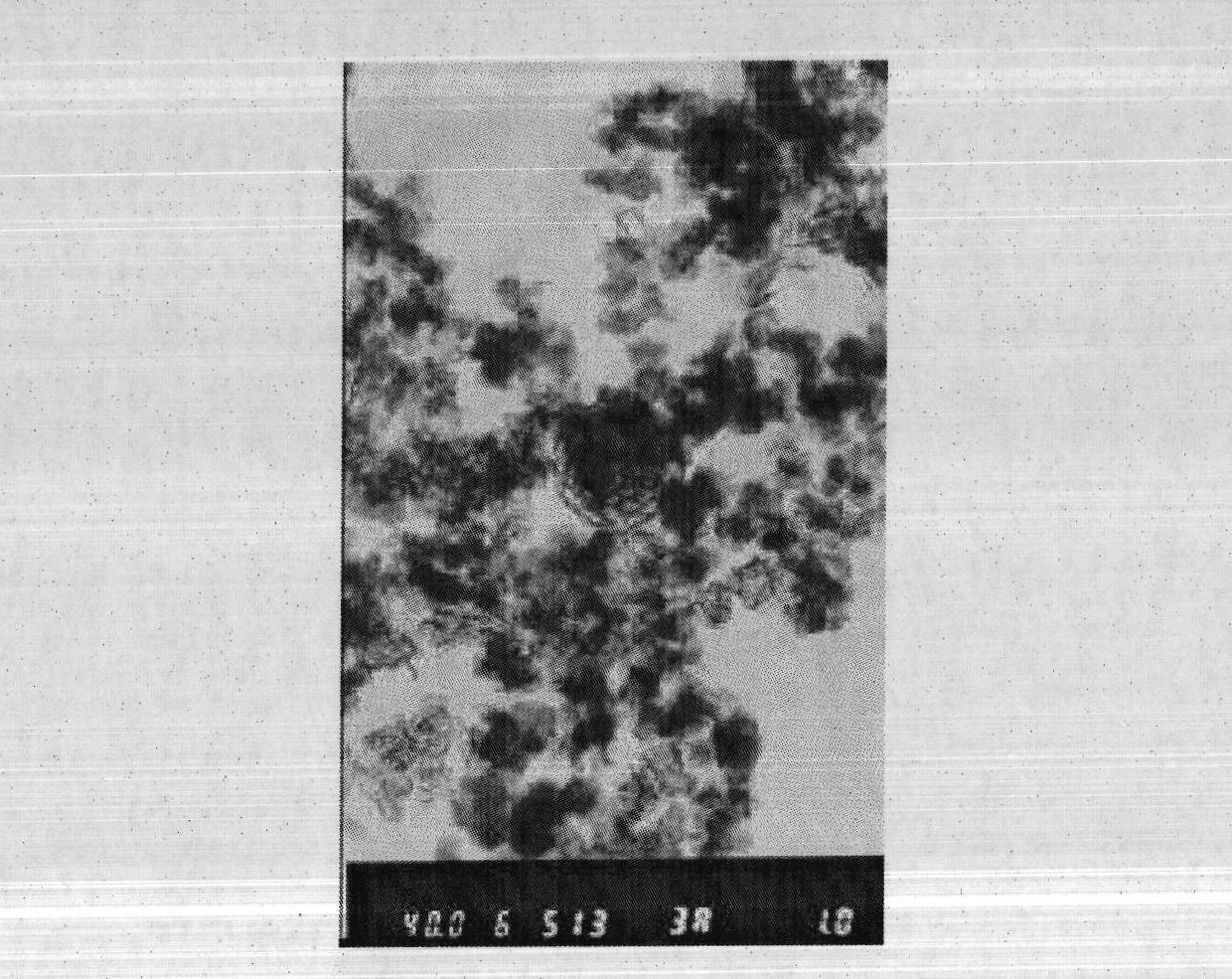

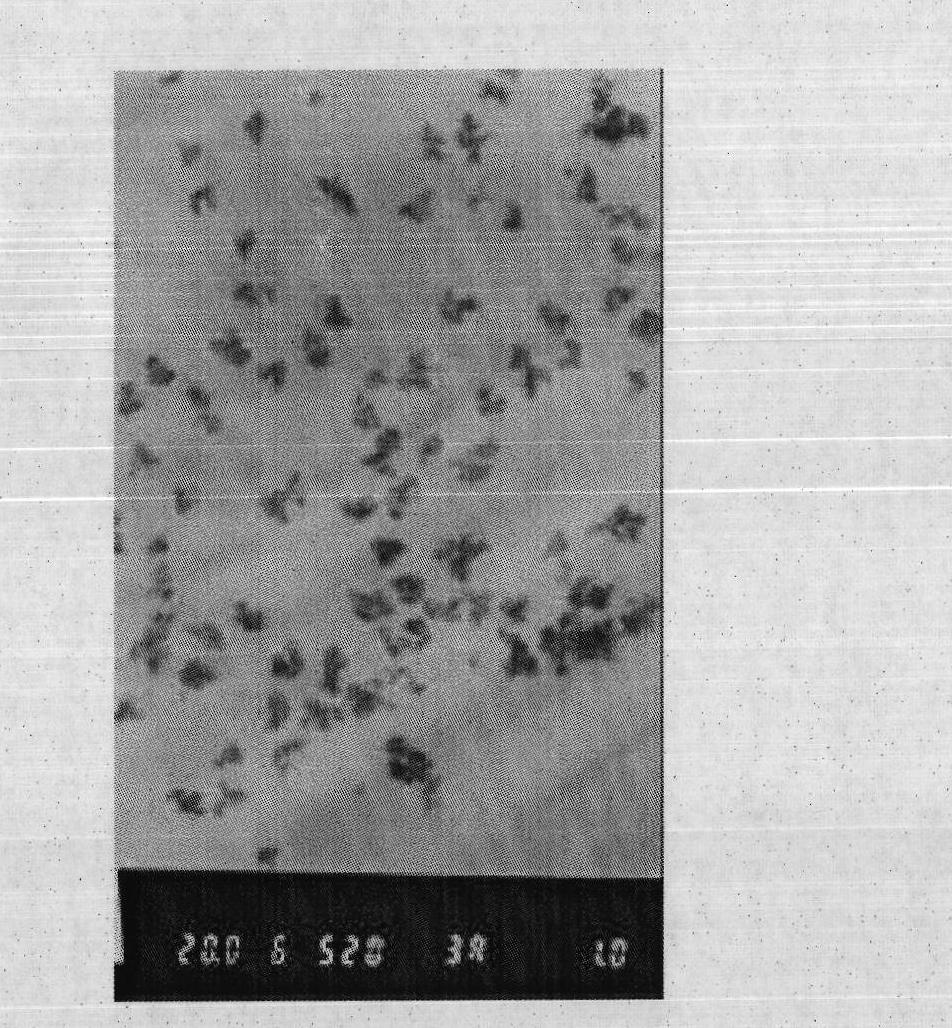

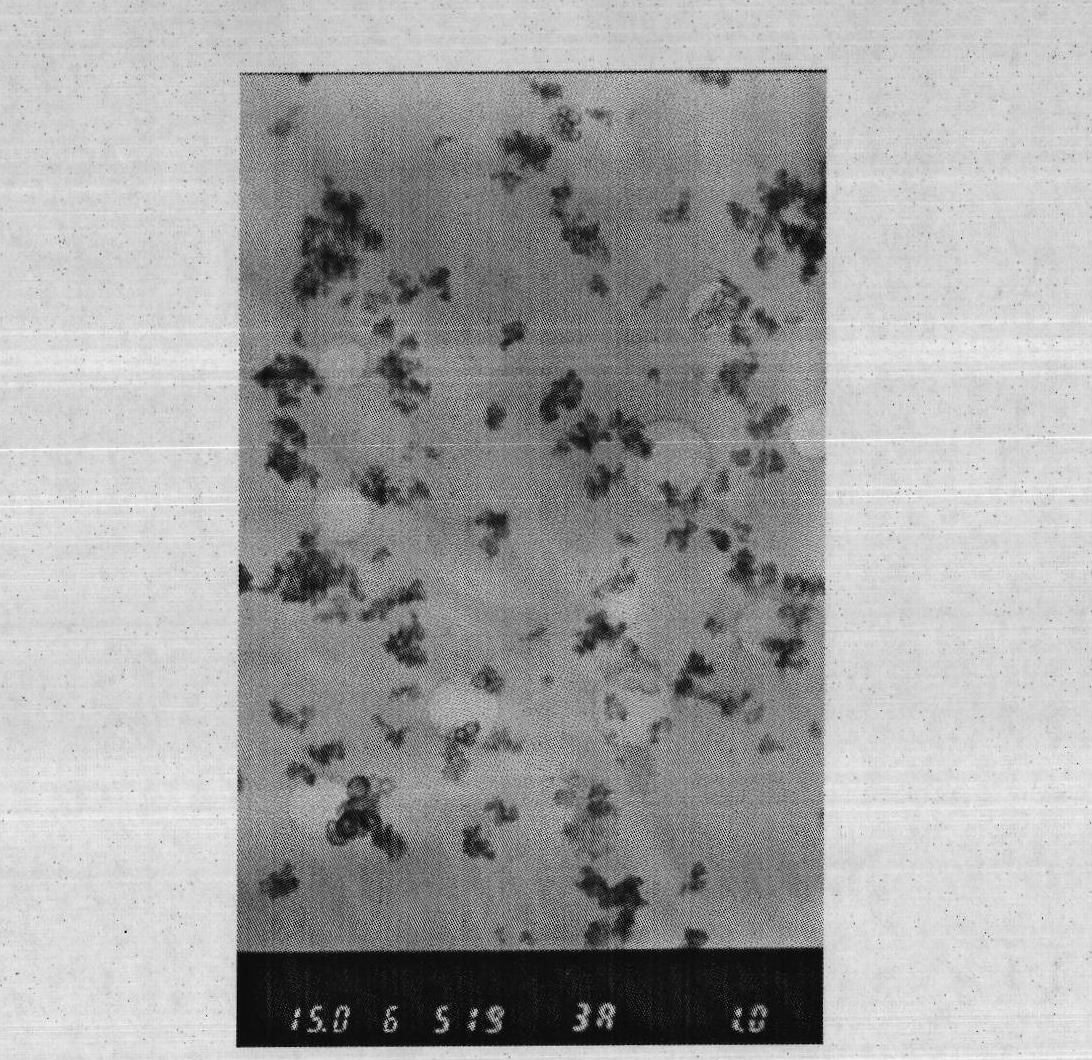

Image

Examples

Embodiment 1

[0020] Add 6.16ml of absolute ethanol, 0.062ml of deionized water, 2.75ml of styrene, 0.039g of AIBN, 0.167g of PVP, and 0.05g of molybdenum disulfide to a three-necked flask in sequence to obtain a reaction solution, and ultrasonically disperse the reaction solution for 10 minutes at room temperature , and then the temperature of the solution was raised to 80° C., and the magnetic stirring was refluxed for 12 hours. After the reaction is complete, add a small amount of absolute ethanol to ultrasonically disperse for 15 minutes, filter, wash with absolute ethanol, take the filtrate, and dry it at 80°C to obtain the modified nanomolybdenum disulfide. Take 0.075g of modified nanomolybdenum disulfide, dissolve it in 2ml of absolute ethanol, add 8ml of butanol, and the resulting solution is directly and stably dispersed in the oily system.

Embodiment 2

[0022] Add 6.16ml of absolute ethanol, 0.062ml of deionized water, 2.75ml of styrene, 0.031g of AIBN, 0.052g of PVP, and 0.05g of molybdenum disulfide to a three-necked flask in sequence to obtain a reaction solution, and ultrasonically disperse the reaction solution for 10 minutes at room temperature , and then the temperature of the solution was raised to 70° C., and the magnetic stirring was refluxed for 12 hours. After the reaction is complete, add a small amount of absolute ethanol to ultrasonically disperse for 15 minutes, filter, wash with absolute ethanol, take the filtrate, and dry it at 80°C to obtain the modified nanomolybdenum disulfide. Take 0.075g of modified nano-molybdenum disulfide, dissolve it in 2ml of absolute ethanol, add 8ml of butanol, and the resulting solution is directly and stably dispersed in the oily system. The amount added is about 0.01-1%.

Embodiment 3

[0024] Add 6.16ml of absolute ethanol, 0.062ml of deionized water, 2.75ml of styrene, 0.031g of AIBN, 0.223g of PVP, and 0.05g of molybdenum disulfide to a three-necked flask in sequence to obtain a reaction solution, and ultrasonically disperse the reaction solution for 10 minutes at room temperature , and then the temperature of the solution was raised to 60° C., and the magnetic stirring was refluxed for 12 hours. After the reaction is complete, add a small amount of absolute ethanol to ultrasonically disperse for 15 minutes, filter, wash with absolute ethanol, take the filtrate, and dry it at 80°C to obtain the modified nanomolybdenum disulfide. Take 0.075g of modified nanomolybdenum disulfide, dissolve it in 2ml of absolute ethanol, add 8ml of butanol, and the resulting solution is directly and stably dispersed in the oily system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com