Cycloastragenol-6-O-beta-D glucoside monohydrate and crystal thereof

A technology of cycloastragenol and glucoside, which is applied in the field of medicine and can solve the problems of easy moisture absorption, difficult storage, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

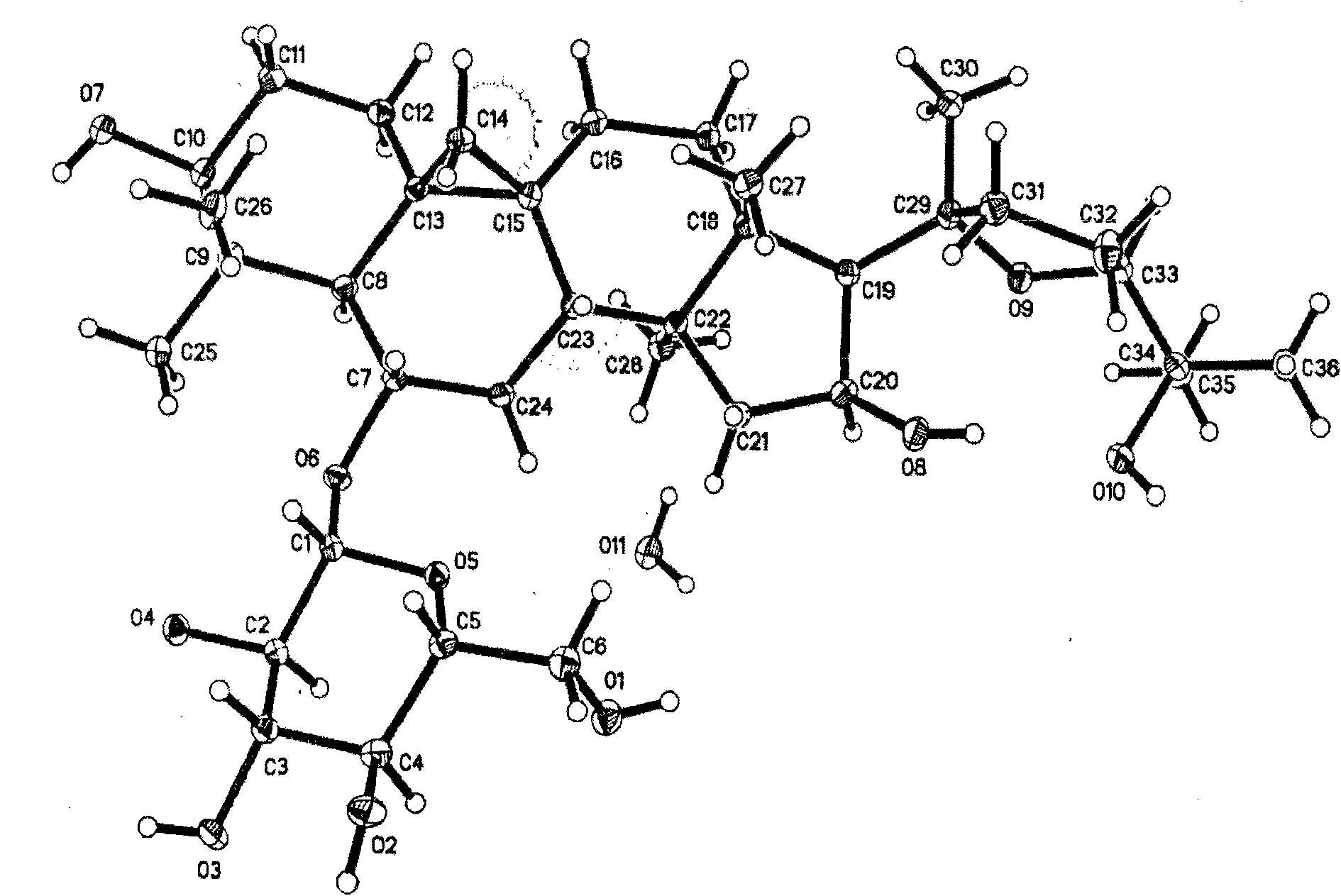

[0039] CMG 5g, heated and dissolved with 50ml 70% (volume) ethanol aqueous solution, filtered while hot, added ethyl acetate to the filtrate under stirring until the volume ratio of ethyl acetate to ethanol in the solution was 10:1, left at room temperature for 24 hours, and white needles were precipitated. crystallized, filtered. Vacuum dry at 105°C for 24 hours, and dry in an infrared dryer for 1 hour to obtain a CMG monohydrate type I single crystal, whose diffraction three-dimensional structure projection diagram is shown in figure 1 ,

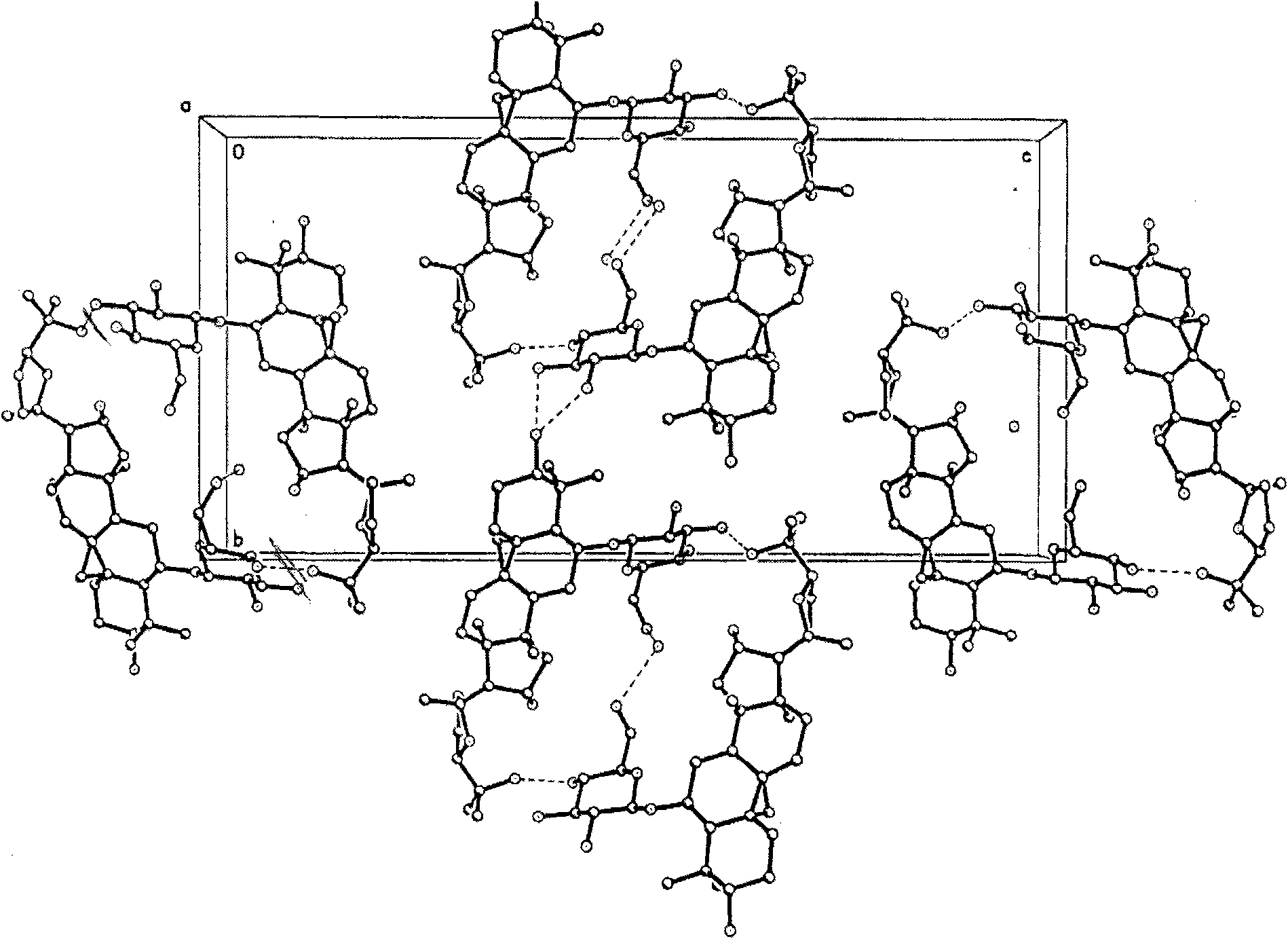

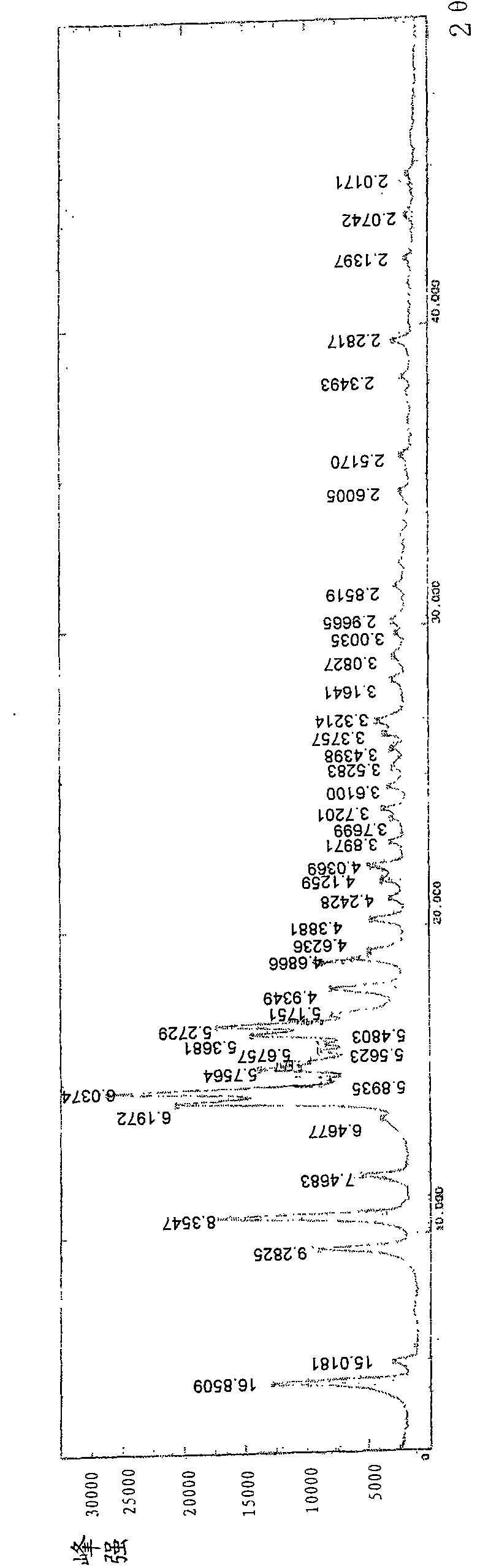

[0040] The projection diagram of the molecules in the single crystal diffraction unit cell along the α-axis direction is shown in figure 2 . The single crystal is ground into powder, and the powder diffraction of CMG monohydrate type I crystal is carried out. The X-ray powder diffraction pattern represented by 2θ angle is shown in image 3 , Table 1 shows the X-ray single crystal diffraction atomic coordinate parameters and equivalent ...

Embodiment 2

[0057] CMG 5g, heated and dissolved with 100ml 80% (volume) ethanol aqueous solution, filtered while it was hot, added ethyl acetate to the filtrate under stirring until the volume ratio of ethyl acetate to ethanol in the solution was 8:1, left at room temperature for 36 hours, and precipitated white Needle crystal, filtered. Vacuum drying at 60°C for 12 hours gave type I CMG monohydrate crystals. Thermogravimetric analysis showed a weight loss of 3.1% at 70-120°C.

Embodiment 3

[0059] CMG 5g, heated and dissolved with 60ml 90% (volume) ethanol aqueous solution, filtered while hot, added ethyl acetate to the filtrate under stirring until the volume ratio of ethyl acetate to ethanol in the solution was 6:1, left at room temperature for 48 hours, and precipitated white Needle crystal, filtered. Dry at room temperature for 48 hours to obtain type I CMG monohydrate crystals. Thermogravimetric analysis showed a weight loss of 2.7% at 70-120°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com