Preparation method of glutinous rice flour grafted polycaprolactone thermoplastic material

A thermoplastic material, polycaprolactone technology, applied in the chemical industry to achieve the effect of increasing cost and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of glutinous rice flour grafted polycaprolactone thermoplastic material, comprising the following steps:

[0023] The commercially available glutinous rice is puffed into glutinous rice sticks by a popping puffing machine, and then directly ground into puffed glutinous rice flour with a mortar, and dried in a vacuum drying oven for 48 hours to remove the adsorbed water on the surface, and stored in a desiccator for future use.

[0024] Add 6ml ε-caprolactone monomer, 2g puffed glutinous rice flour, and 2ml dry pyridine into a four-necked flask, stir to make it fully mixed, and put the four-necked flask into an oil bath at 120°C; Nitrogen is passed through the four-necked flask, degassed and dehydrated for 2 hours, and impurities such as moisture and oxygen in the flask are removed;

[0025] Weigh 0.5g of stannous octoate and put it into dry pyridine to form a 20% pyridine solution. Under the protection of nitrogen, add the 20% pyridine solution drop...

Embodiment 2

[0028] A preparation method of glutinous rice flour grafted polycaprolactone thermoplastic material, comprising the following steps:

[0029] The commercially available glutinous rice is puffed into glutinous rice sticks by a popping puffing machine, and then directly ground into puffed glutinous rice flour with a mortar, and dried in a vacuum drying oven for 48 hours to remove the adsorbed water on the surface, and stored in a desiccator for future use.

[0030] Add 13ml ε-caprolactone monomer, 4g puffed glutinous rice flour, and 2ml dry pyridine into a four-necked flask, stir to make it fully mixed, and put the four-necked flask into an oil bath at 120°C; Nitrogen was passed through the four-neck flask, degassed and dehydrated for 2 hours, and impurities such as moisture and oxygen in the flask were removed.

[0031] Weigh 0.5g of stannous octoate and put it into dry pyridine to form a 20% pyridine solution. Under the protection of nitrogen, add the 20% pyridine solution dro...

Embodiment 3

[0034] A preparation method of glutinous rice flour grafted polycaprolactone thermoplastic material, comprising the following steps:

[0035] The commercially available glutinous rice is puffed into glutinous rice sticks by a popping puffing machine, and then directly ground into puffed glutinous rice flour with a mortar, and dried in a vacuum drying oven for 48 hours to remove the adsorbed water on the surface, and stored in a desiccator for future use.

[0036] Add 10ml ε-caprolactone monomer, 3g puffed glutinous rice flour, and 2ml dry pyridine into a four-necked flask, stir to make it fully mixed, and put the four-necked flask into an oil bath at 120°C; Nitrogen was passed through the four-neck flask, degassed and dehydrated for 2 hours, and impurities such as moisture and oxygen in the flask were removed.

[0037] Weigh 0.5g of stannous octoate and put it into dry pyridine to form a 20% pyridine solution. Under the protection of nitrogen, add the 20% pyridine solution dro...

PUM

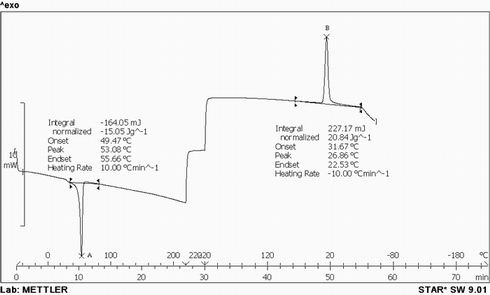

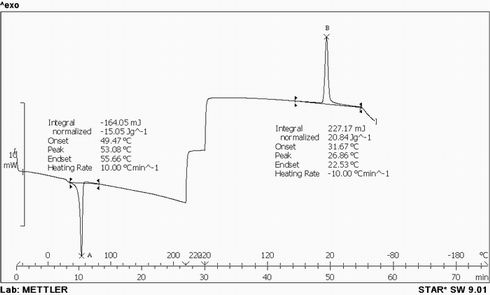

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com