Method for extracting carthamin yellow and carthamin from safflower

A technology of safflower yellow pigment and extraction method, which is applied in the field of extracting safflower yellow pigment and red pigment, can solve the problems that are not easy to be applied to large-scale industrial production, large yellow pigment loss, unfavorable industrial production, etc. Large-scale production, the price can be recycled and reused, and the effect of increasing the value of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

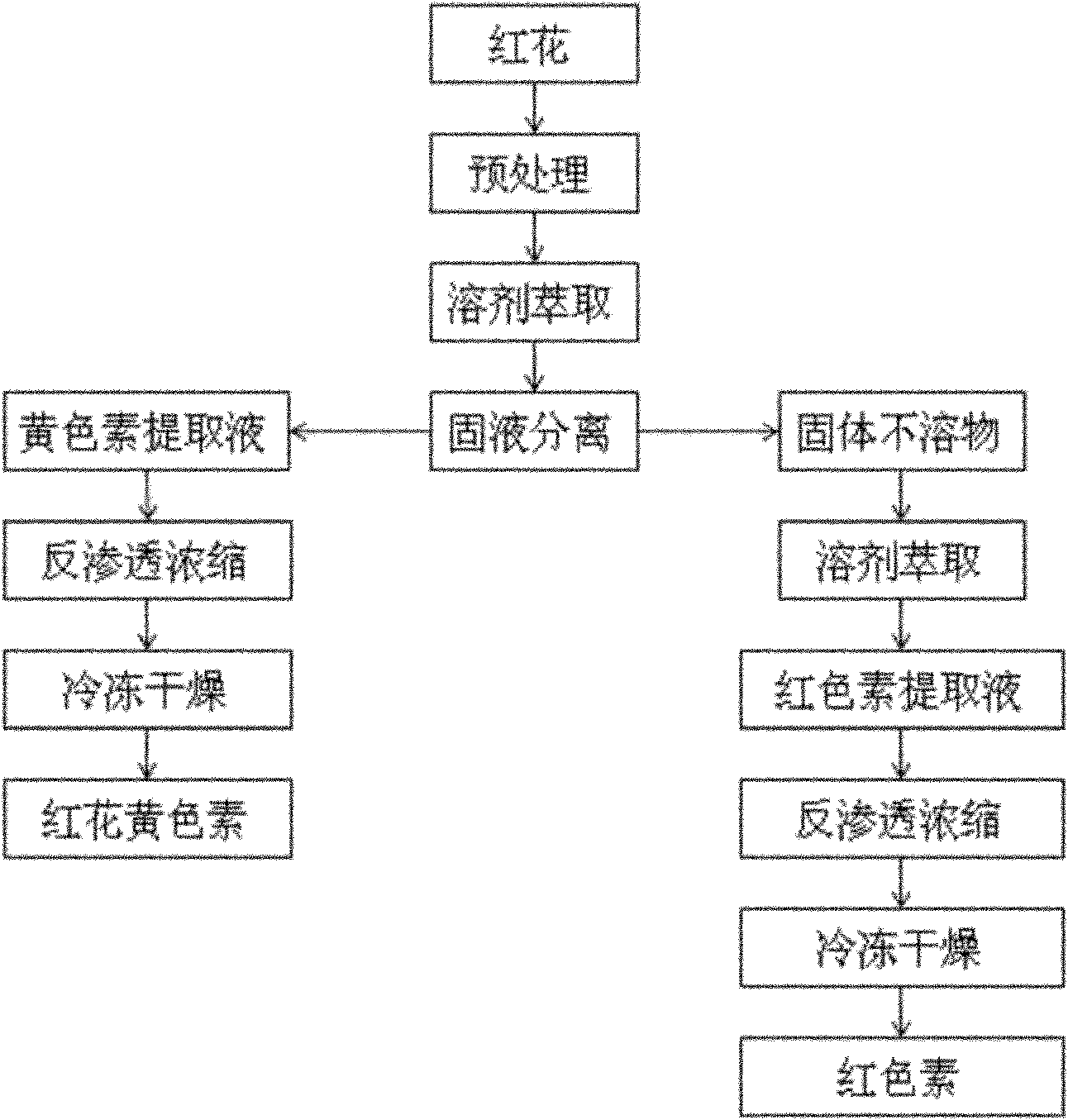

Method used

Image

Examples

Embodiment 1

[0024] Take 1 kg of safflower raw material, remove the impurities (branches, leaves, etc.) in it, put it evenly in a container, place it in a microwave device with a frequency of 1500 MHz, and dry and sterilize it at 30 ° C for 8 minutes. Then put the treated safflower material into the reactor, add 8kg of deionized water, and carry out liquid-solid separation after stirring for 6h, then wash the solid insolubles twice with 3kg of deionized water respectively, and combine all the extracts to obtain Safflower Yellow Extract. Put the solid insoluble matter obtained above into a reactor, add 6 kg of boric acid-potassium chloride-sodium hydroxide buffer solution with pH=8, and stir for 6 hours, then carry out solid-liquid separation, and then wash with 2 kg of the above-mentioned alkaline buffer solution The solid matter was collected for 3 times, and all the extracts were combined to obtain the red pigment extract. The obtained extracts were respectively concentrated with revers...

Embodiment 2

[0026] Take 2 kg of safflower raw material, remove the impurities (branches, leaves, etc.) in it, put it evenly in a container, place it in a microwave device with a frequency of 2000 MHz, and dry and sterilize it at 40 ° C for 5 minutes. Then put the treated safflower material into the reactor, add 20kg of distilled water, stir for 8 hours, and then carry out liquid-solid separation, then wash the solid insoluble matter with 5kg of distilled water for 3 times, and combine all the extracts to obtain the safflower yellow pigment extract. Put the solid insoluble matter obtained above into a reactor, add 15 kg of disodium hydrogen phosphate-sodium hydroxide buffer solution with pH=12, and stir for 10 h, then carry out solid-liquid separation, and then wash the solid with 6 kg of the above-mentioned alkaline buffer solution 2 times, and all the extracts were combined to obtain the red pigment extract. The obtained extracts were respectively concentrated with reverse osmosis polya...

Embodiment 3

[0028] Take 2.5 kg of safflower raw material, remove the impurities (branches, leaves, etc.) in it, put it evenly in the container, place it in a microwave device with a frequency of 2500 MHz, and dry and sterilize it at 50 ° C for 9 minutes. Then put the processed safflower material into the reactor, add 30kg of deionized water, carry out liquid-solid separation after 10h, then wash the solid insolubles 4 times with 5kg of deionized water respectively, and combine all the extracts to obtain the safflower Anthocyanin Extract. Put the solid insolubles obtained above in a reactor, add 10 kg of boric acid-potassium chloride-sodium hydroxide buffer solution with pH=10, and stir for 8 hours, then carry out solid-liquid separation, and then wash with 3 kg of the above-mentioned alkaline buffer solution The solid matter was collected 4 times, and all the extracts were combined to obtain the red pigment extract. The obtained extracts were respectively concentrated with reverse osmosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com