Salt resistant high-temperature resistant solid-free environment-friendly well drilling and completing integrated working fluid

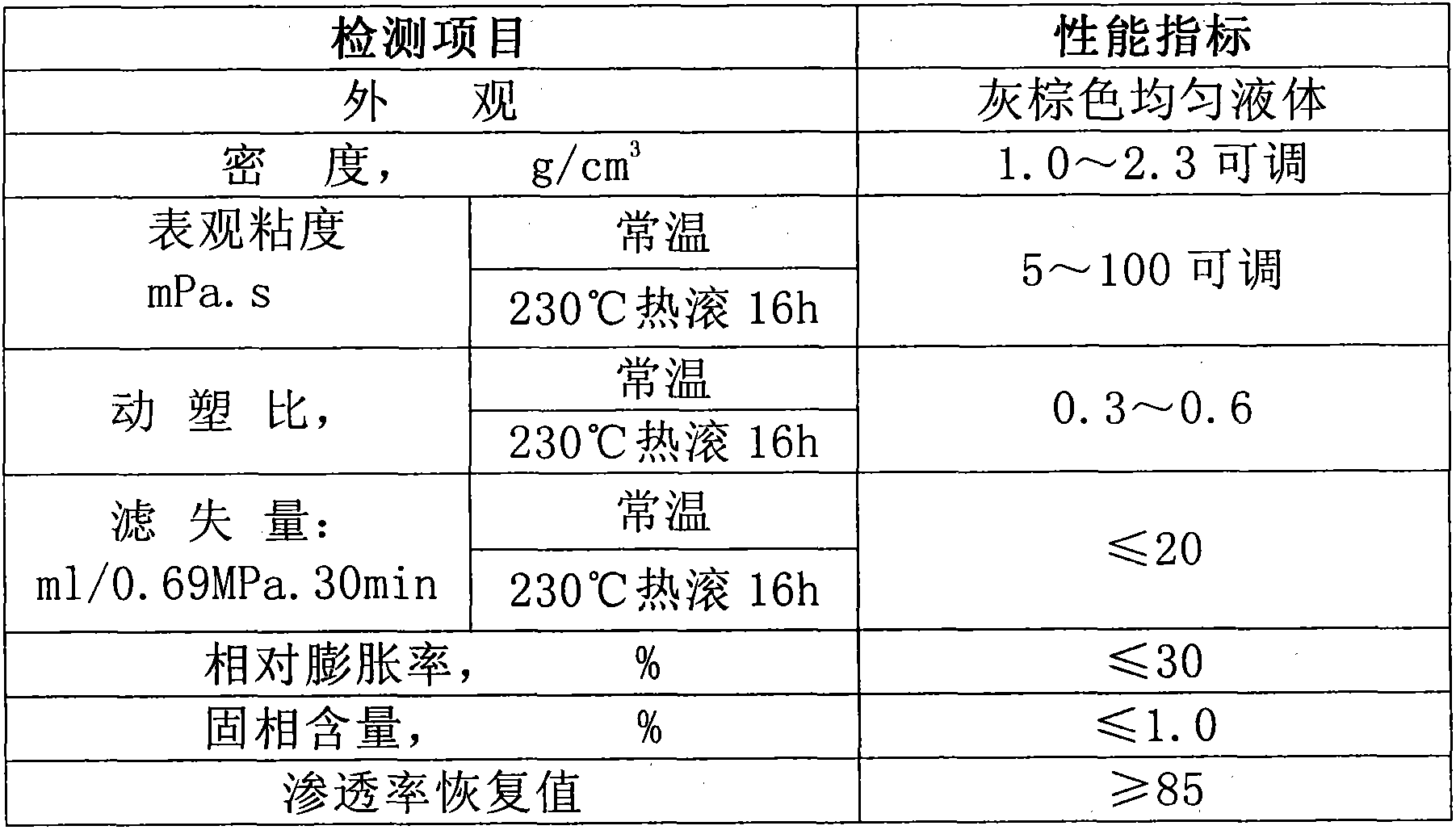

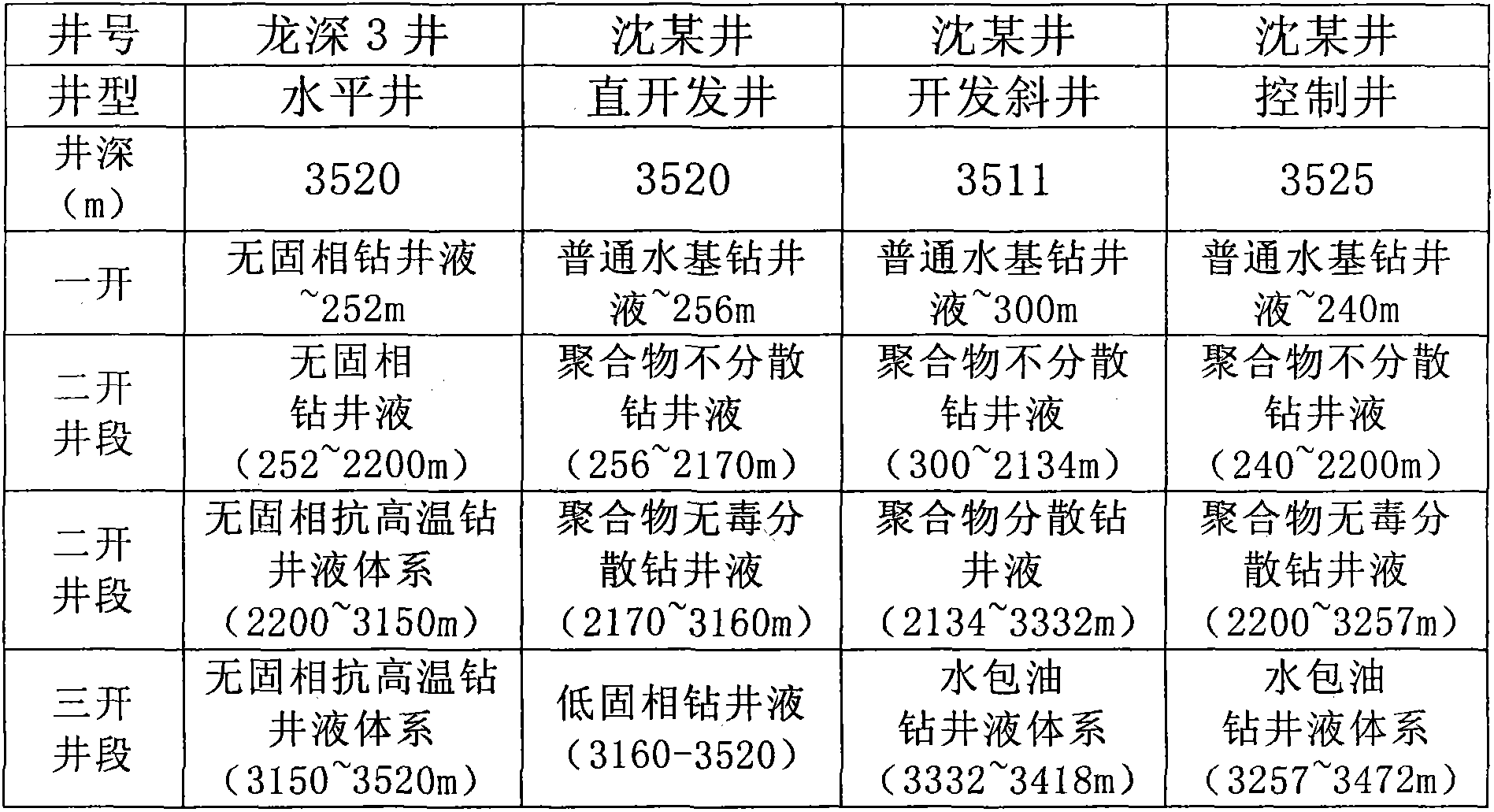

A high-temperature resistant, solid-free technology, applied in the field of oil drilling, can solve the problems of restricting the development and promotion of solid-free drilling and completion fluids, and achieve the effects of optimizing the overall performance of the system, scientific and rational formulation, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The preparation process of the integrated working fluid for high temperature resistance, salt resistance and solid-free environment-friendly drilling and completion of the present invention is as follows:

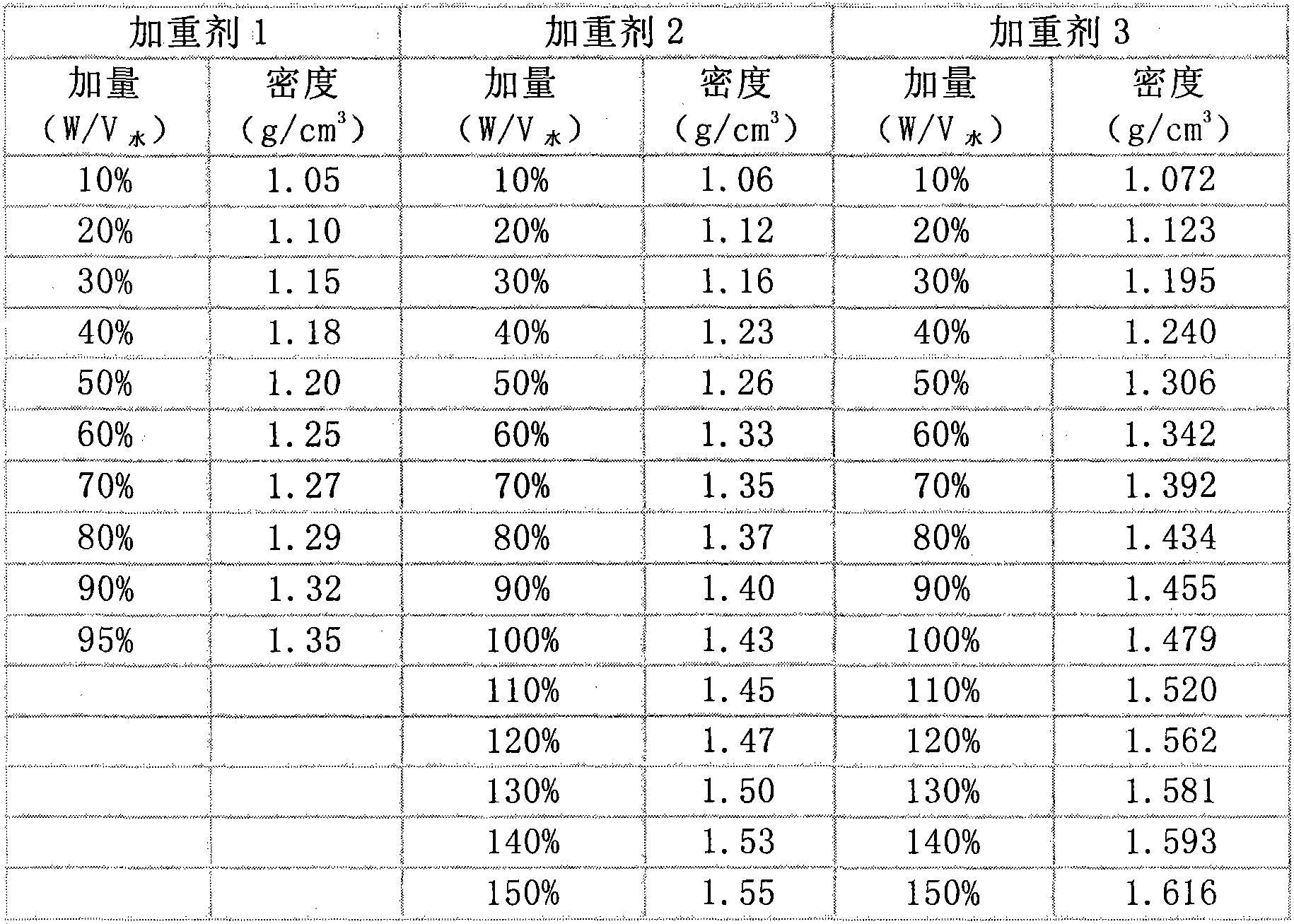

[0070] (1) According to the designed drilling fluid volume (in 100 cubic meters, the specific gravity is 1.2g / cm 3 For example), prepare the raw materials of formate, tackifier, fluid loss reducer, oil layer protective agent and polyalcohol anti-slump agent;

[0071] (2) Inject 83.9 cubic meters of clean water into the mud preparation tank, add 36.1 tons of formate under stirring, and prepare 100 cubic meters of drilling and completion base fluid with a specific gravity of 1.2:

[0072] (3) In the state of high-speed stirring, add a hydraulic jet pump at the same time, and add 0.4HEC as a thickener to the dosing tank; the dissolution is uniform, and no micelles appear;

[0073] (4) Add 3.0 tons of fluid loss reducer under stirring, if the temperature resistance cond...

Embodiment 2

[0094] A high-temperature and salt-resistant, solid-free, environment-friendly drilling and completion integrated working fluid, each cubic meter of solution contains the following components in the following mass ratios: 10kg formate, 0.5kg thickener, 3.0kg fluid loss reducer, 2.0kg kg oil layer protective agent, 2.0 kg polyalcohol anti-slump agent, and the rest are water.

[0095]According to the designed drilling fluid volume, prepare the raw materials of formate, viscosifier, fluid loss reducer, oil layer protective agent and polymerized alcohol anti-slump agent; inject clean water into the mud mixing tank, and add formic acid while stirring Salt, prepared as base fluid for drilling and completion; under high-speed stirring, add a hydraulic jet pump at the same time, and add a thickener carboxymethyl hydroxyethyl cellulose (CMHEC) into the liquid dispensing tank; dissolve evenly, without glue If the temperature resistance condition is greater than 150℃, the amount of fluid...

Embodiment 3

[0097] A high-temperature and salt-resistant, solid-free, environment-friendly drilling and completion integrated working fluid, each cubic meter of solution contains the following components in the following mass ratios: 260kg formate, 0.6kg thickener, 4.0kg fluid loss reducer, 3.0kg kg oil layer protective agent, 3.0 kg polyalcohol anti-slump agent, and the rest are water.

[0098] According to the designed drilling fluid volume, prepare the raw materials of formate, viscosifier, fluid loss reducer, oil layer protective agent and polymerized alcohol anti-slump agent; inject clean water into the mud mixing tank, and add formic acid while stirring salt, prepared as base fluid for drilling and completion; under high-speed stirring, add a hydraulic jet pump at the same time, and add a viscosity-increasing agent xanthan gum (HX) to the dosing pool; dissolve evenly, and no micelles can appear; Add fluid loss reducer under stirring. If the temperature resistance condition is greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com