Low-temperature acidification corrosion inhibitor and preparation method thereof

An acidification corrosion inhibitor and low-temperature technology, which is applied in the field of acidification corrosion inhibitor and its preparation, can solve the problems of restricting the large-scale use and promotion of low-temperature corrosion inhibitors, poor corrosion inhibition effect of working pipe strings, and high production cost of corrosion inhibitors. , achieve the effect of low production cost, little environmental pollution and reduced corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 300kg of refined methanol in the reactor, then add 500kg of benzyl dimethyl dodecyl ammonium bromide, 120kg of propynyl alcohol, 80kg of cetylpyridine bromide, at a speed of 60 rpm Stir for 30 minutes, after stirring evenly, a uniform reddish-brown liquid is formed, which is the low-temperature acidification corrosion inhibitor.

[0021] Evaluation of corrosion inhibition effect:

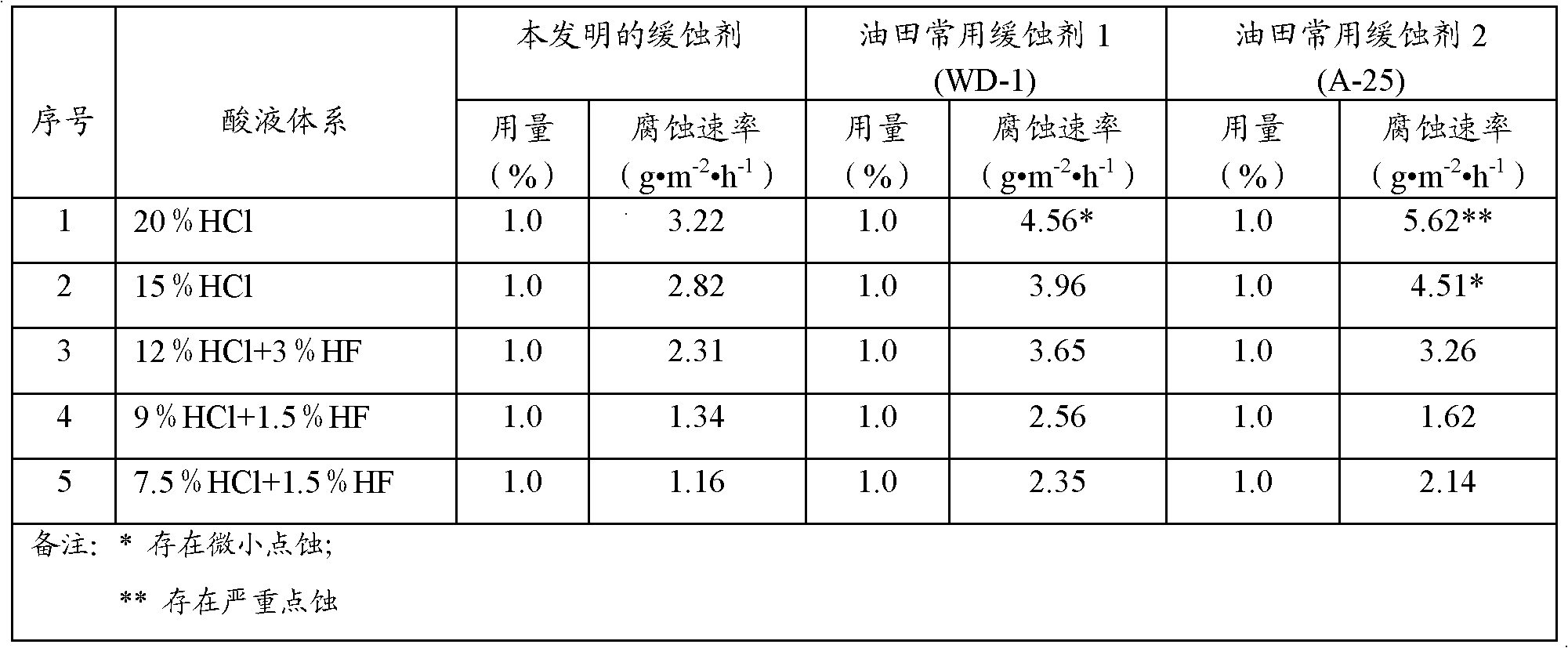

[0022] Static corrosion test test: 90°C, N80 steel sheet, test for 4 hours, the concentration of corrosion inhibitor is 1.0%, the corrosion rate results in different acid liquid systems are shown in Table 1:

[0023] Table 1 Test Comparison of Corrosion Inhibitors

[0024]

[0025] From the corrosion rate results in 5 kinds of acid liquid systems under the same addition and the same experimental conditions, it can be seen that the corrosion inhibitor of the present invention is better than the low-temperature acidification corrosion inhibitor commonly used at present, and the surface ...

Embodiment 2

[0027] Add 350kg of refined methanol in the reactor, then add 280kg of dodecyldimethylbenzyl ammonium chloride, 300kg of 1,4-butynediol and 70kg of chlorinated dodecylpyridine, with 60 rpm Stir at a speed of 30 minutes per minute. After stirring evenly, a uniform reddish-brown liquid is formed, and the low-temperature acidification corrosion inhibitor is obtained.

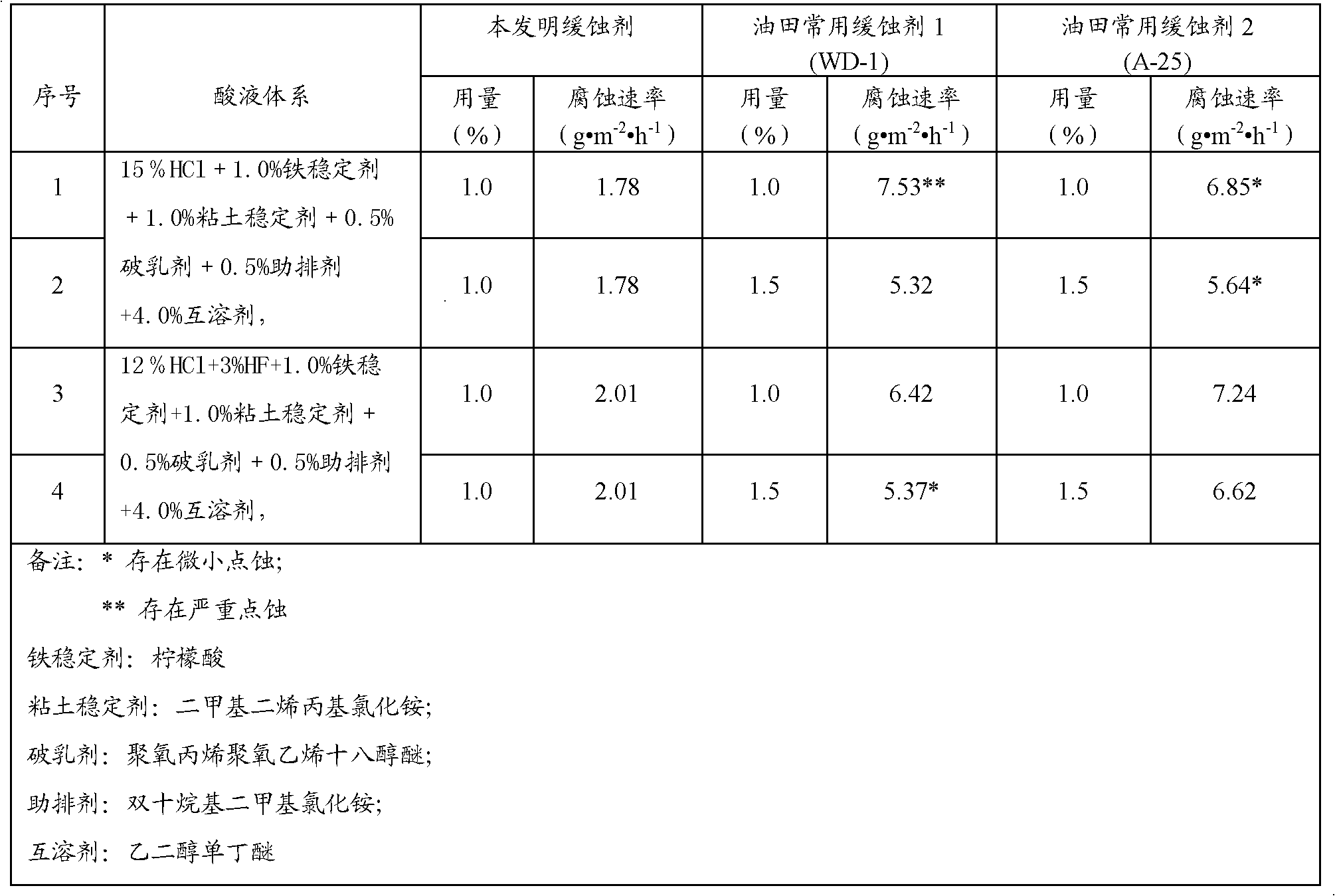

[0028] Test with the acid liquid system used in the actual acidizing operation in the oil field, static corrosion test: 90°C, N80 steel sheet, test for 4 hours.

[0029] Table 2 Tests in the acid system

[0030]

[0031] It can be seen from the experimental results in Table 2 that under the same amount of addition, the corrosion resistance of the low-temperature corrosion inhibitor of the present invention in acid liquid is better than that of the low-temperature acidification corrosion inhibitor commonly used in oil fields at present. Furthermore, even if the addition amount of the currently used low-temperatu...

Embodiment 3

[0033] Add 400kg of refined methanol in the reactor, then add 400kg of benzyl dimethyl dodecyl ammonium bromide, 100kg of methyl butynol, 100kg of chlorinated dodecylpyridine, at 60 rpm Stir at a high speed for 30 minutes. After stirring evenly, a uniform reddish-brown liquid is formed, which is the low-temperature acidification corrosion inhibitor.

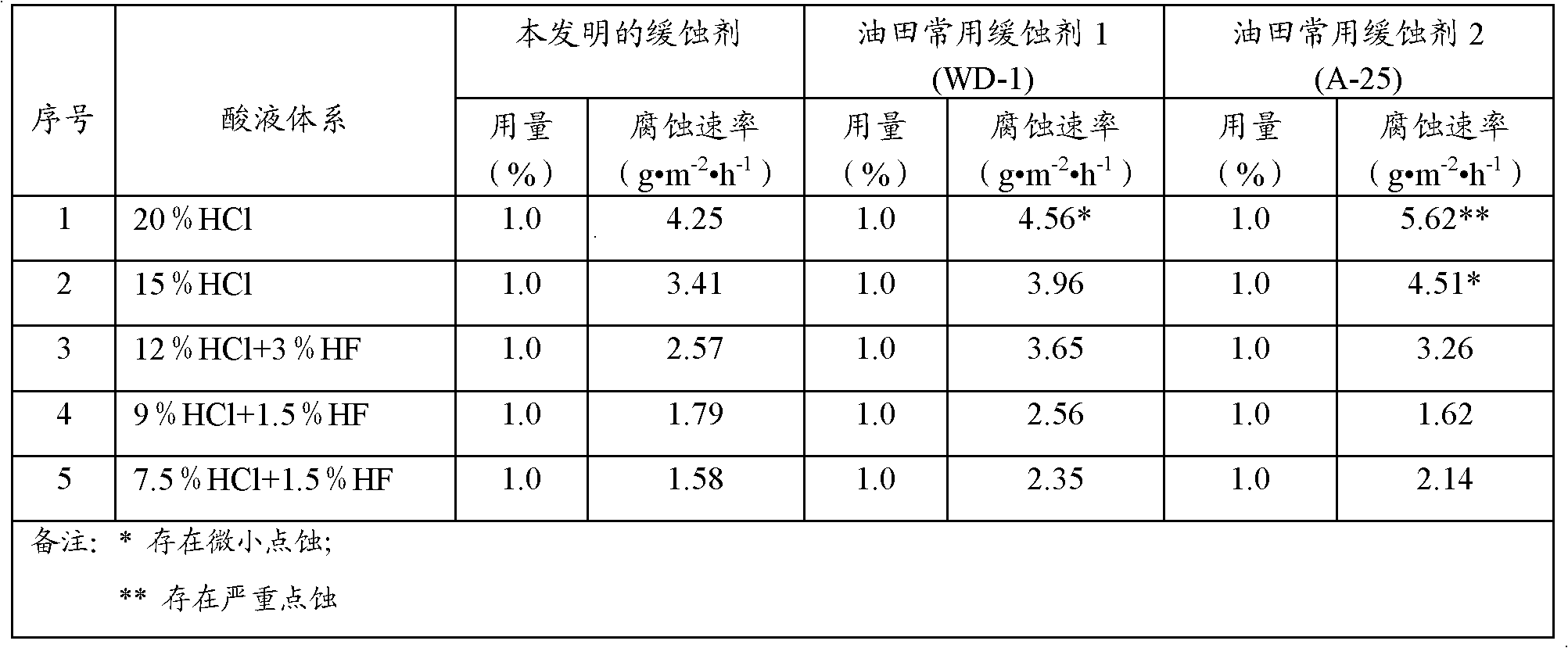

[0034] Table 3 Test Comparison of Corrosion Inhibitors

[0035]

[0036] From the corrosion rate results in 5 kinds of acid liquid systems under the same addition and the same experimental conditions, it can be seen that the corrosion inhibitor of the present invention is better than the low-temperature acidification corrosion inhibitor commonly used at present, and the surface of the test piece is smooth and free of corrosion. pitting phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com