Quartz glass tube silicon chip bracket component

A quartz glass tube and silicon wafer technology, applied in electrical components, semiconductor devices, furnaces, etc., can solve problems such as low power consumption, small footprint, and inability to meet sintering process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

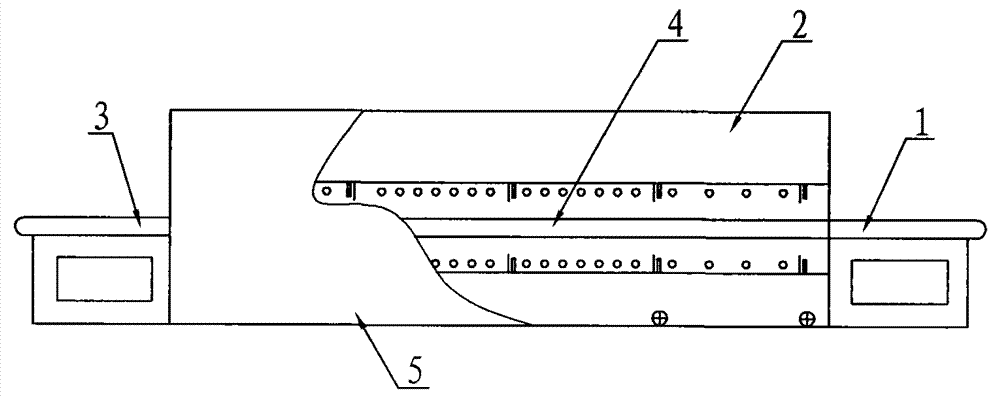

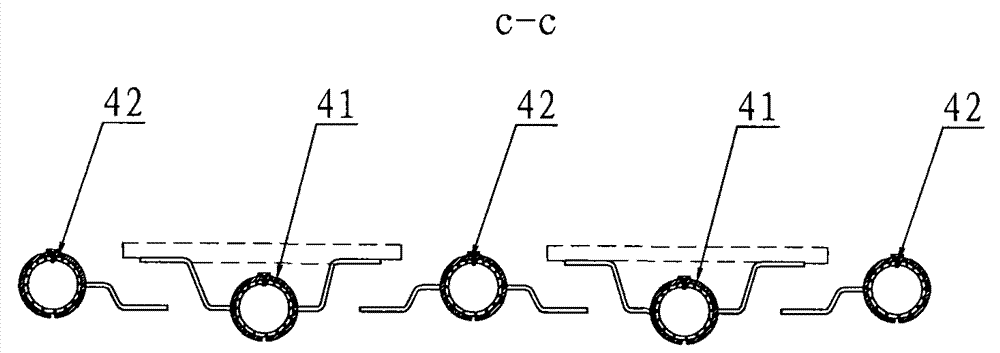

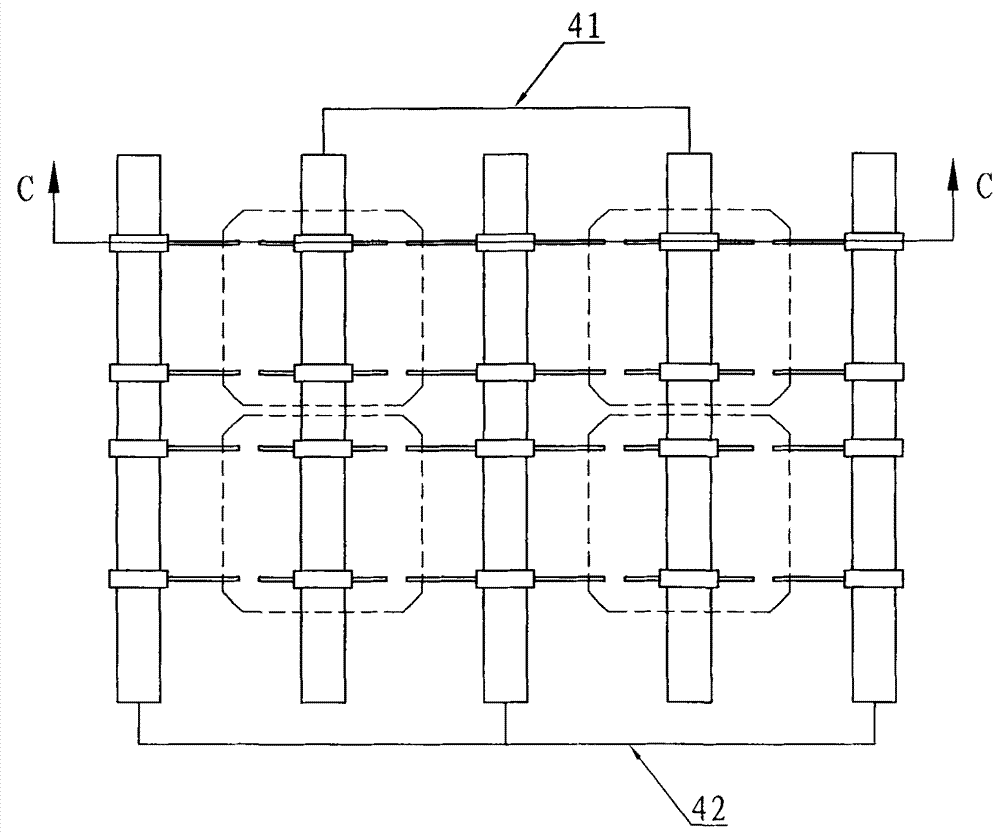

[0018] The quartz glass tube silicon wafer carrier components, such as Figure 2 to Figure 5 As shown, it consists of a quartz glass tube 411, a metal sleeve 412, a standoff 413 and a limit screw 414. The standoff 413 is fixed on the metal sleeve 412, and the metal sleeve 412 is provided with a threaded hole 416 and an opening 417. Both The center line of the center line is located on the same axis, and the limited holes 415 are opened equidistantly along the axial direction on the quartz glass tube 411, the metal sleeve 412 is set on the quartz glass tube 411, and the limit screw 414 is screwed into the screw thread on the metal sleeve 412 hole 416, and extend into the limit hole 415 on the quartz glass tube 411, so that the metal sleeve 412 is installed on the quartz glass tube 411 at equal intervals. Coating 418.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com