Preparation method of pitch microsection

A technology of asphalt and thin slices, which is applied in the field of analysis of organic polymer substances, can solve the problems of troublesome preparation methods and high production costs of light slices or thin slices, and achieve the effects of low cost, good flatness and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

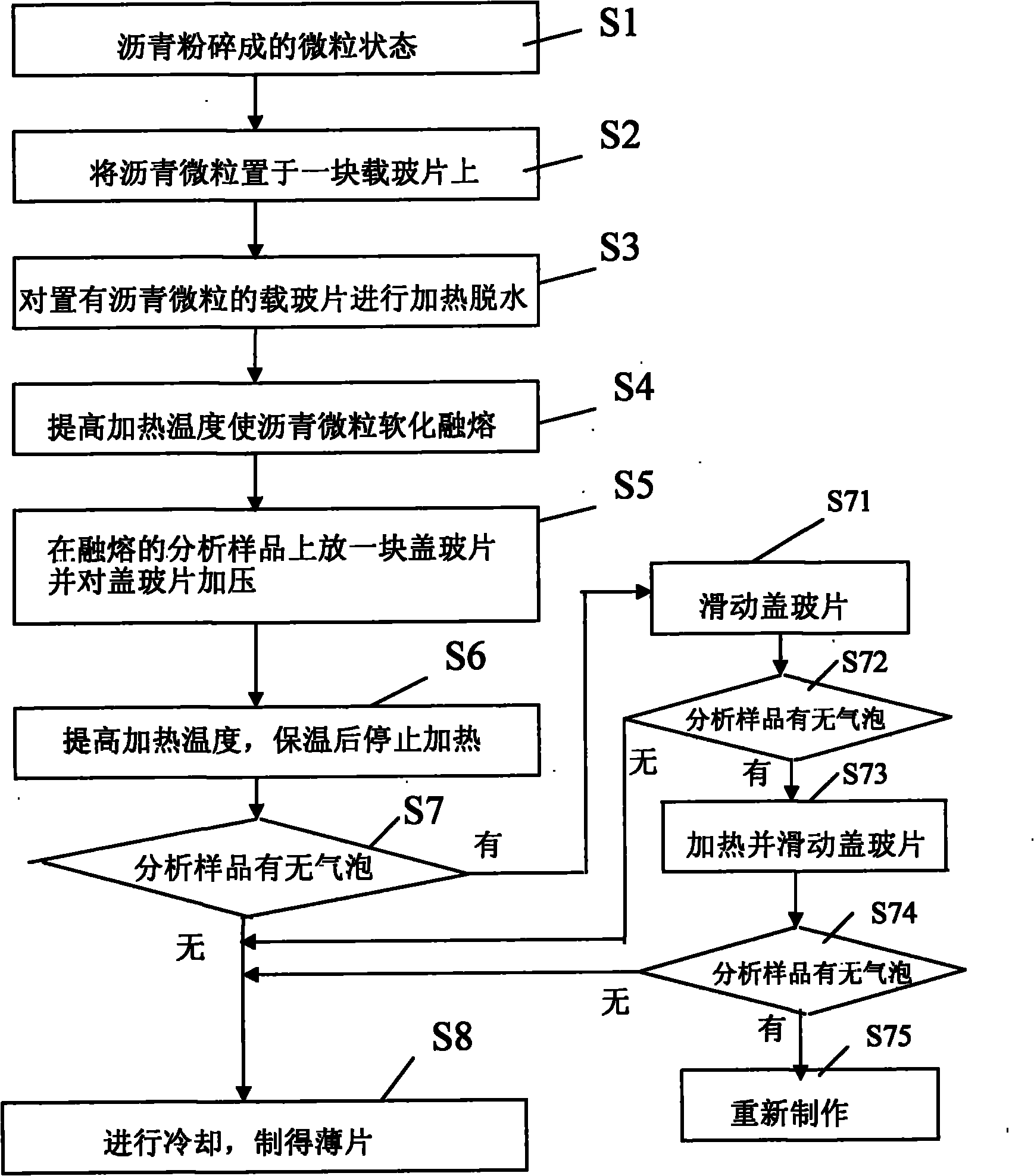

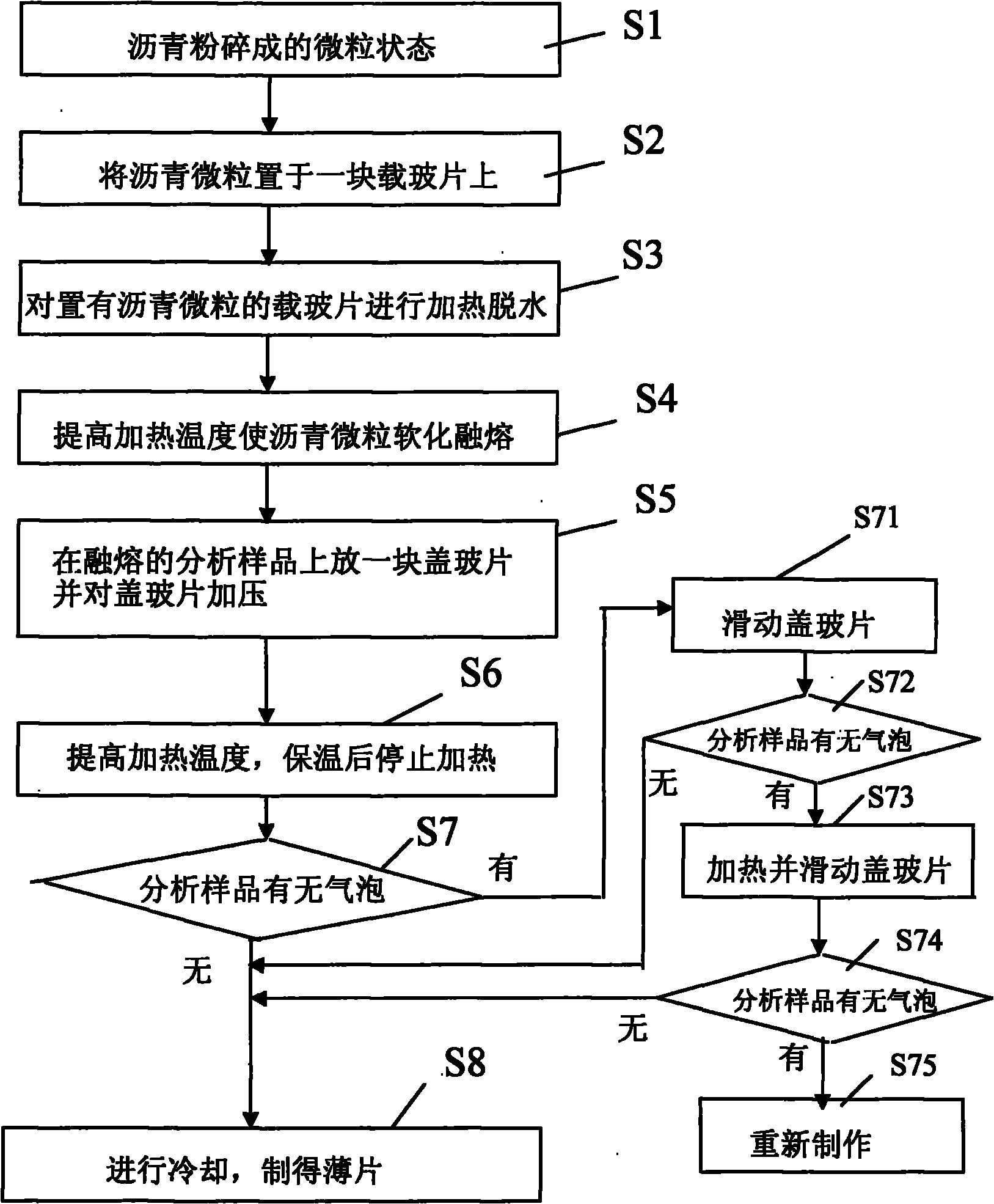

[0033] see figure 1 , figure 1 It is a flow chart of the preparation method of asphalt microflakes of the present invention. The present invention uses coal tar pitch to heat and melt, has certain cohesiveness, and resolidifies when cooled. At this time, there is no volatilization loss, and its internal structure is not destroyed. Thin slices, that is, the present invention adopts a hot-press curing method to make thin slices, and the specific manufacturing steps are as follows.

[0034] S1, pulverize the asphalt into particles, and the particle size of each particle is less than 3mm.

[0035] S2. Weigh 4-8 mg of asphalt particles and place them on a glass slide.

[0036] S3, heating and dehydrating the glass slide with asphalt particles for 5-15 minutes, preferably at a heating temperature of 90-100°C. The heating method can be heated in an oven, and at this time, the glass slide with the asphalt particles is placed in the oven; the glass slide with the asphalt particles c...

Embodiment 1

[0049] Crush the medium-temperature asphalt to a particle size below 3mm. Weigh 4 mg of pitch particles and place on a glass slide. Put it into an oven with a set temperature of 90°C for heating and dehydration for 5 minutes. After dehydration, increase the heating temperature to 105°C to soften and melt the analysis sample. Put a cover glass on the molten sample, and add a 50g weight on top. Raise the temperature to 120° C. and keep warm for 15 minutes, then take out the slide glass and cover glass and the analysis samples between them. Slightly slide the coverslip to remove air bubbles. The sample to be analyzed is cooled into thin slices.

Embodiment 2

[0051] Crush the medium-temperature asphalt to a particle size below 3mm. Weigh 6 mg of pitch particles and place on a glass slide. Put it into an oven with a set temperature of 95°C for heating and dehydration for 8 minutes. After removing the water, increase the heating temperature to 110°C to soften and melt the analysis sample. Put a cover glass on the molten sample, and add a 20g weight on top. Raise the temperature to 130° C. and keep warm for 10 minutes, then take out the slide glass and cover glass and the analysis samples between them. Slightly slide the coverslip to remove air bubbles. The sample to be analyzed is cooled into thin slices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com