New polymer blue-ray engraving material

A technology of polymer and new material, applied in the direction of photo-engraving process, optics and opto-mechanical equipment of pattern surface, can solve the problem of difficult discharge of toxic developer, achieve good photocrosslinking curing performance, excellent impact strength and Scratch fastness, high fineness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

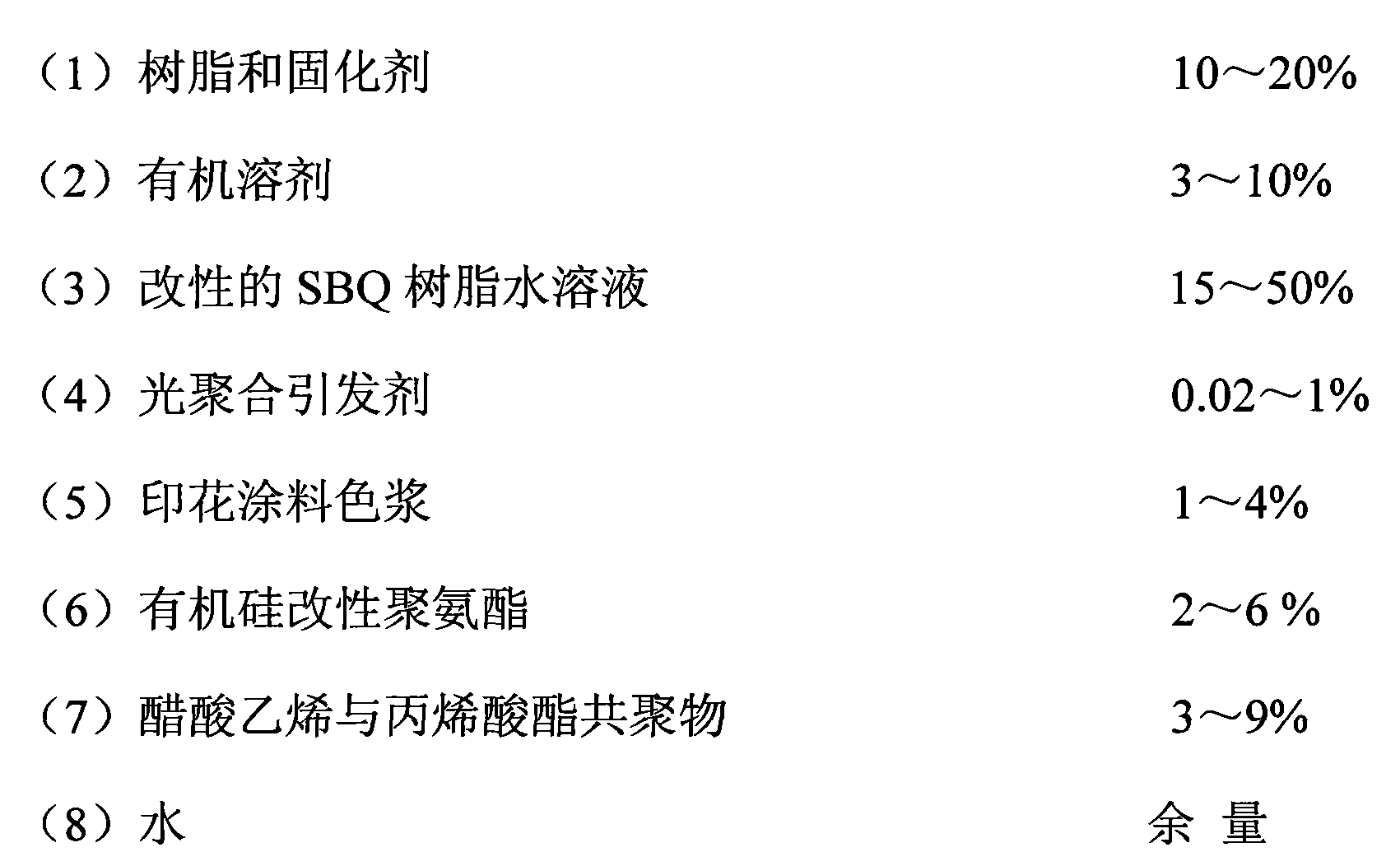

[0030]

Embodiment 2

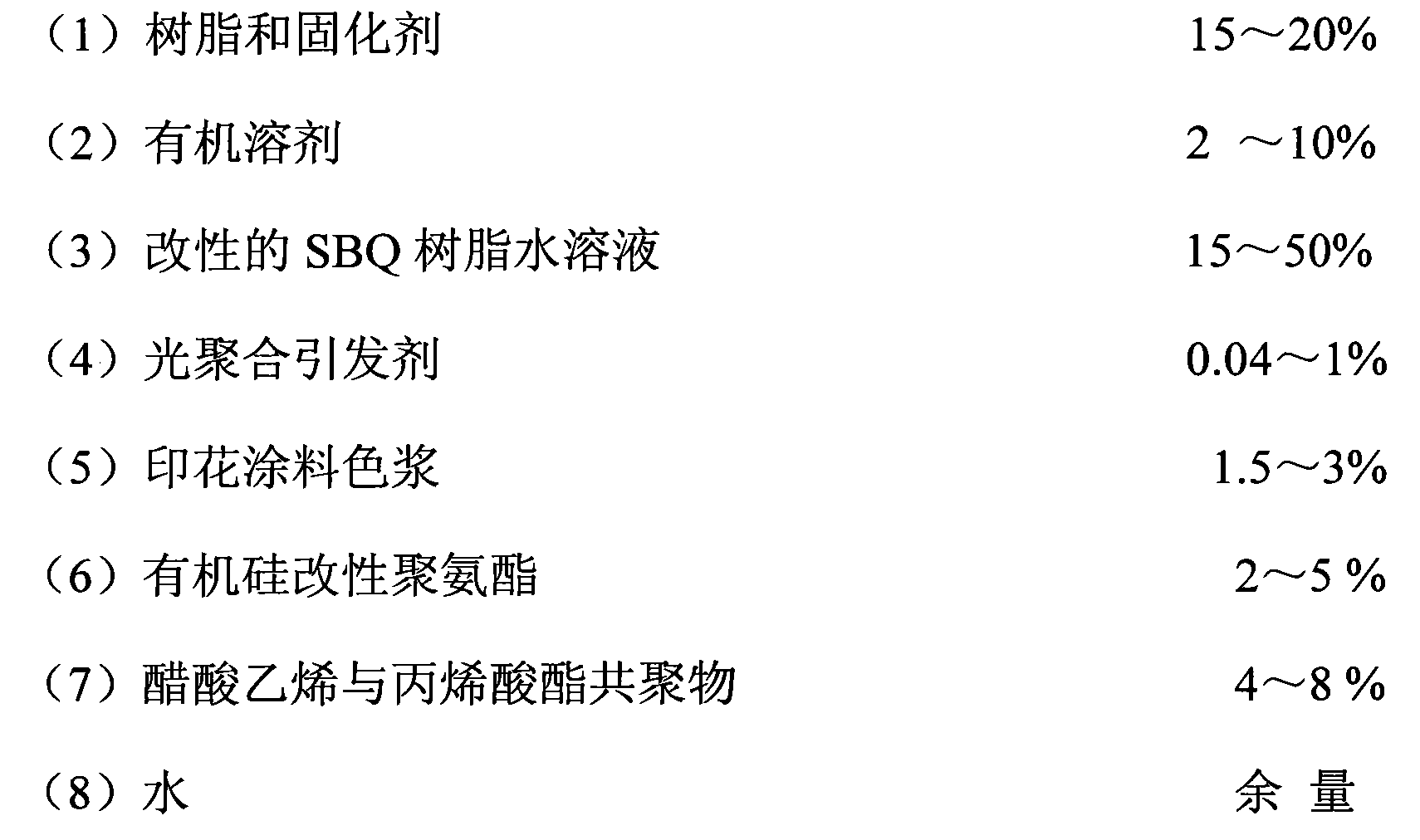

[0032]

Embodiment 3

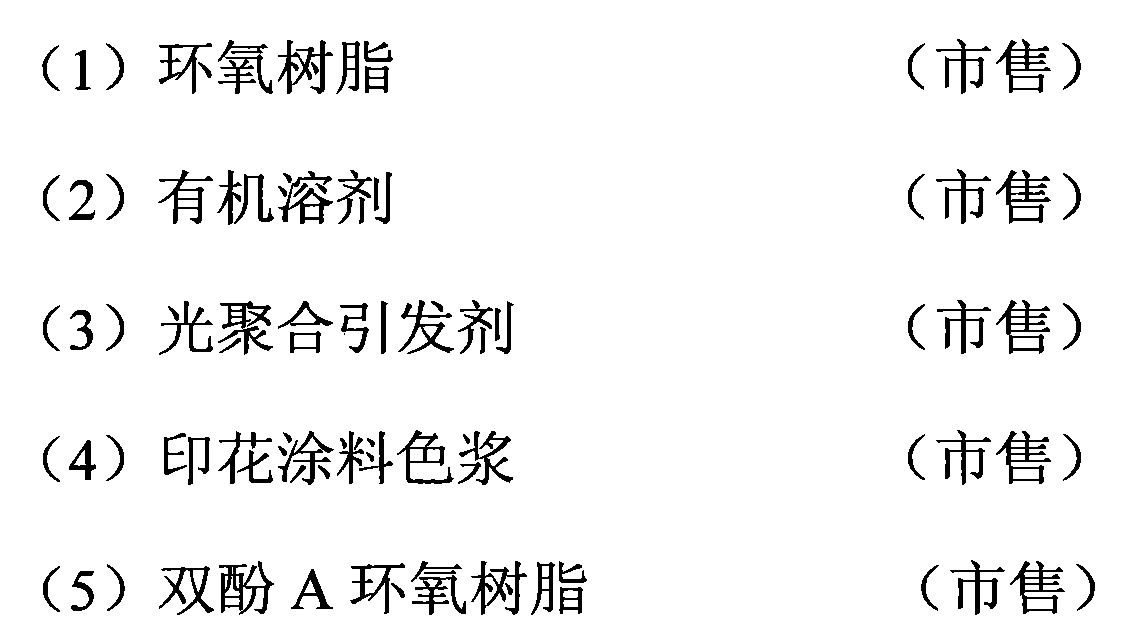

[0034]

[0035] In the above examples, all raw materials can be purchased from the market, or prepared with reference to the preparation examples disclosed in the present invention.

[0036] Wherein: the preparation and use method of vinyl acetate-acrylate copolymer emulsion:

[0037] (1) Add deionized water, alkylphenol polyoxyethylene ether and polyvinyl pyrrolidone into the enamel kettle with stirrer and reflux condenser, then slowly raise the temperature to about 40°C, and stir well. (2) Add about 1 / 5 of the total amount of mixed monomers (vinyl acetate, butyl acrylate and 2-ethylhexyl acrylate) into the reactor, and then add about 1 / 3 of the total amount of ammonium persulfate with water Add it to the reaction kettle after melting, and divide the remaining ammonium persulfate into 5 parts. Except one part is added at the end, the remaining four parts are added to the reaction kettle every 40 minutes. (3) Raise the temperature of the material in the reactor to 68-72°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com