Uninterrupted chemical battery

A chemical battery and battery technology, applied in the electronics industry, chemical industry, electric power, electrosynthesis industry, mining and metallurgy fields, can solve the problems of power consumption and waste, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

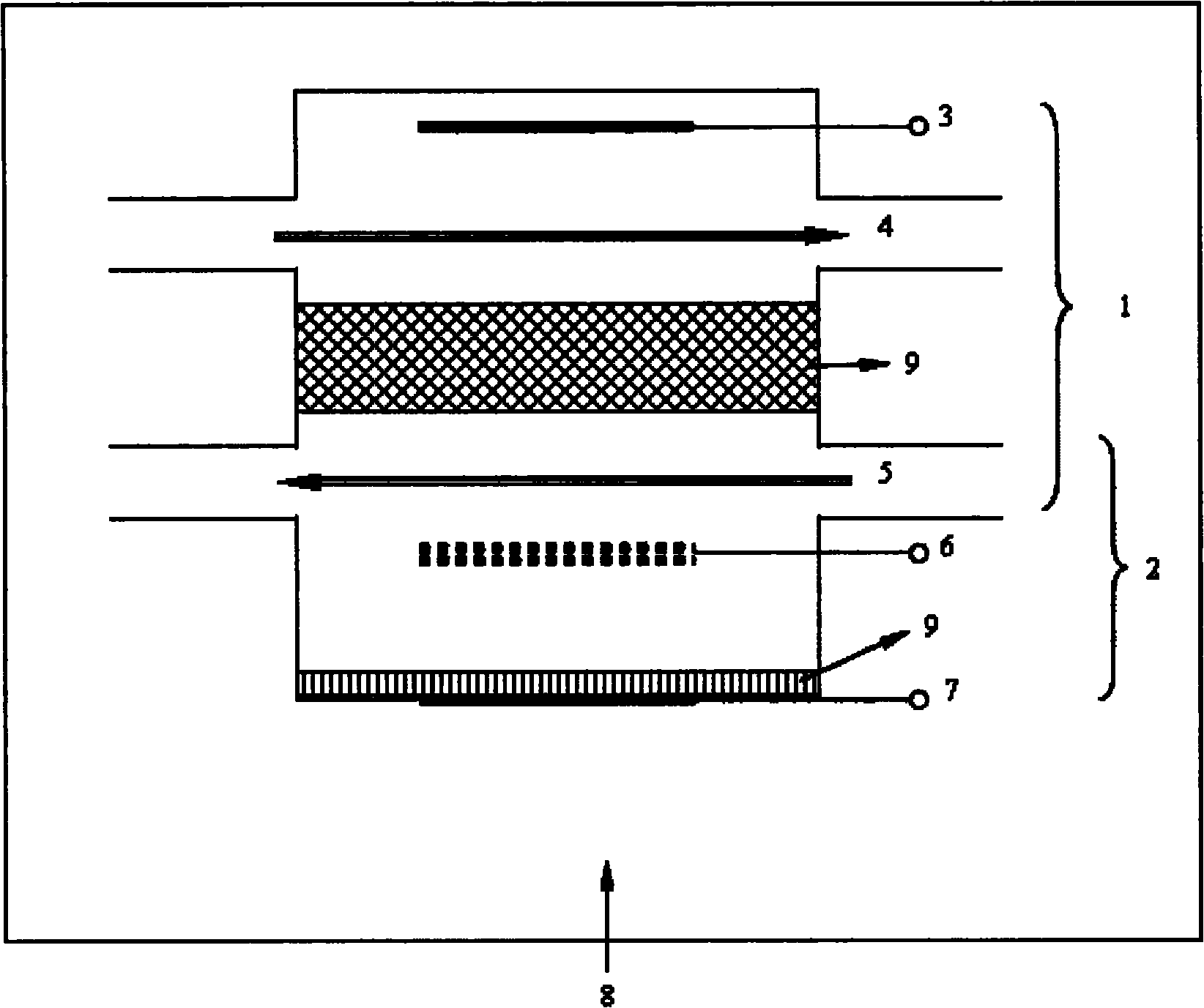

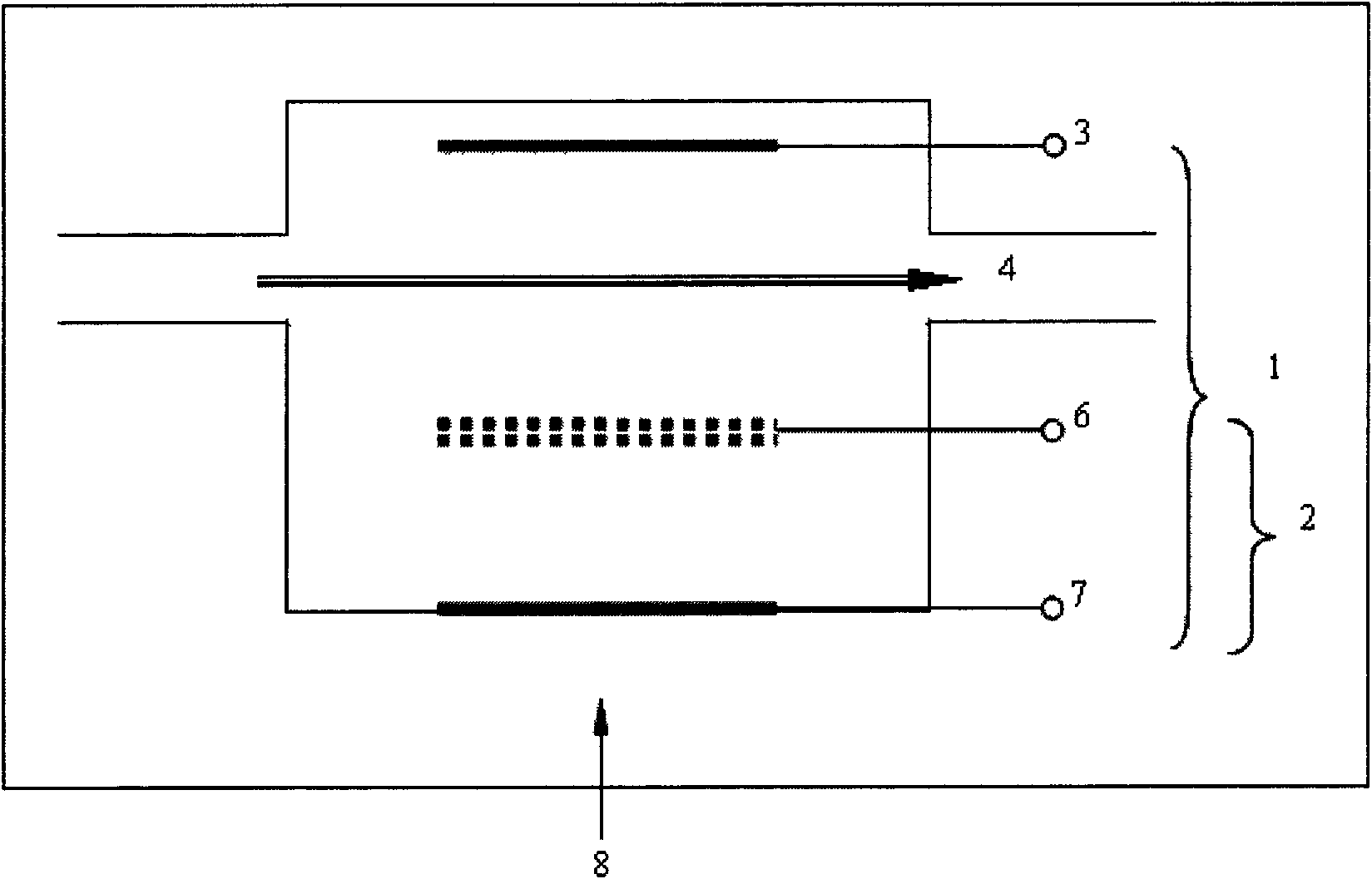

[0023] An uninterrupted flow battery with electrosynthesis function includes an electrosynthesis unit 1 and an external power supply unit 2 . Electrosynthesis unit 1 is composed of positive electrode 3 for catalytic oxidation, electrosynthesis electrolyte solution 4, diaphragm 9, negative electrode electrolyte solution 5 and negative electrode 6, wherein electrosynthesis electrolyte solution 4 contains reducing raw materials; power supply unit 2 consists of negative electrode 6, negative electrode electrolyte Solution 5, diaphragm 9, catalytic oxygen reduction electrode 7 and gas or air 8 containing oxygen; diaphragm 9 can be used between electrosynthesis electrolyte solution 4 and negative electrode electrolyte solution 5, and between negative electrode electrolyte solution 5 and catalytic oxygen reduction electrode 7 Separation; the electrosynthesis unit 1 and the power supply unit 2 are connected through a common negative pole 6 .

example 2

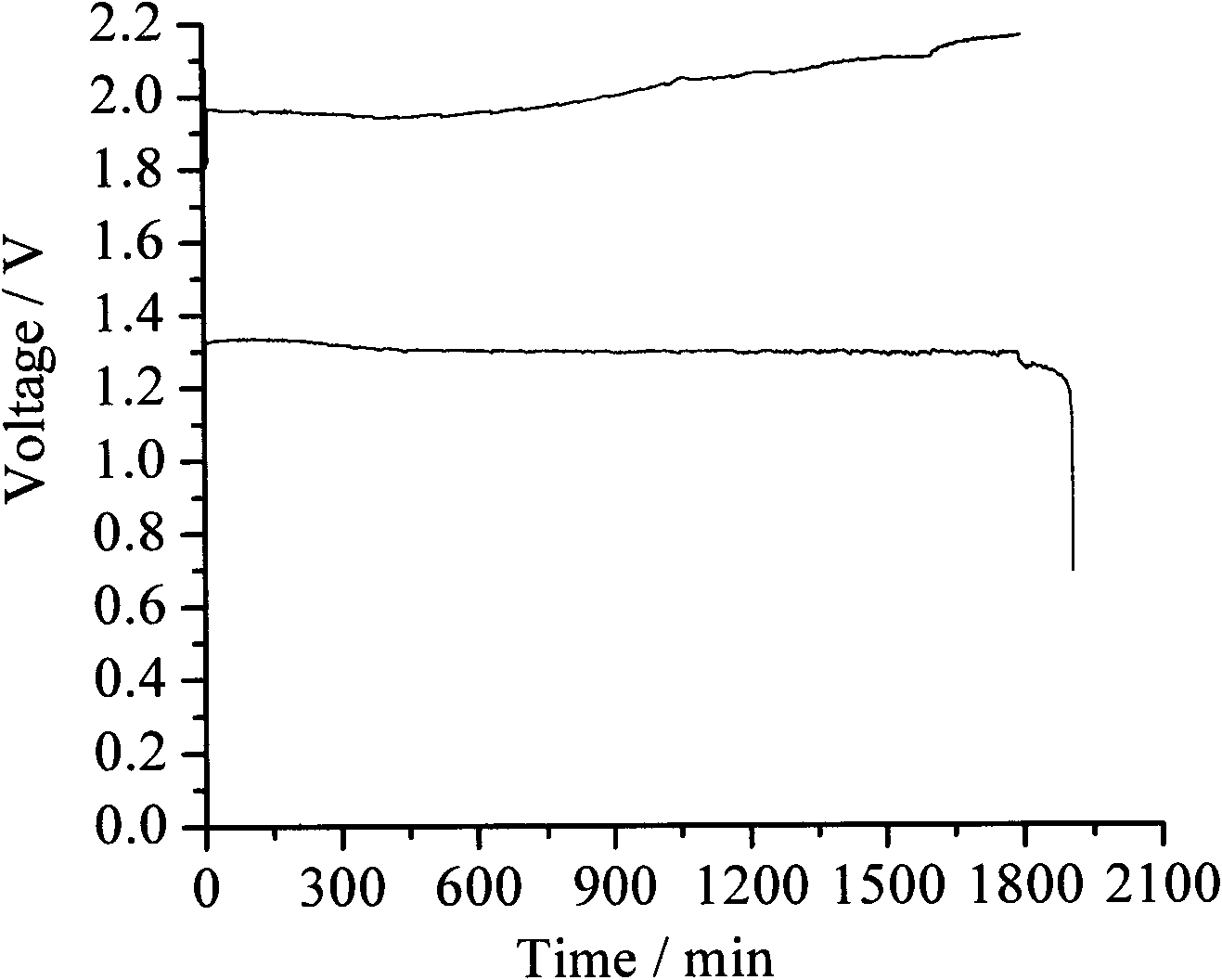

[0026] Using graphitized carbon felt as the catalytic oxidation positive electrode 3, the negative electrode 6 uses graphite as the current collector, graphitized carbon felt as the catalytic interface, and the full liquid phase electrode pair V(III) / V(II) as the active material, catalytic oxidation of the positive electrode 3 The negative electrode 6 is separated by an anion exchange membrane 9 to form an electrosynthesis unit 1, and the electrosynthesis electrolyte solution 4 is a 3M HBr+0.1M cystine aqueous solution, wherein cystine is a reducing raw material, water is a solvent, and VBr4 is a supporting electrolyte , negative electrode electrolyte solution 5 is 1MV(III)+3M H 2 SO 4 Aqueous solution; the power supply unit consisting of the negative electrode 6 and the oxygen reduction electrode 7 directly uses an anion exchange membrane to separate the two electrodes, and the oxygen-containing gas is passed into the oxygen reduction electrode 7 of the power supply unit at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com