Electric locomotive non-power-off neutral section passing-electric energy quality comprehensive compensation device and method

A technology for electric locomotives and power quality, applied in reactive power compensation, reactive power adjustment/elimination/compensation, harmonic reduction devices, etc. Operation, high-speed train speed and other issues are greatly affected, to achieve the effect of reducing difficulty and cost, no loss of traction, and reducing the impact of negative sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

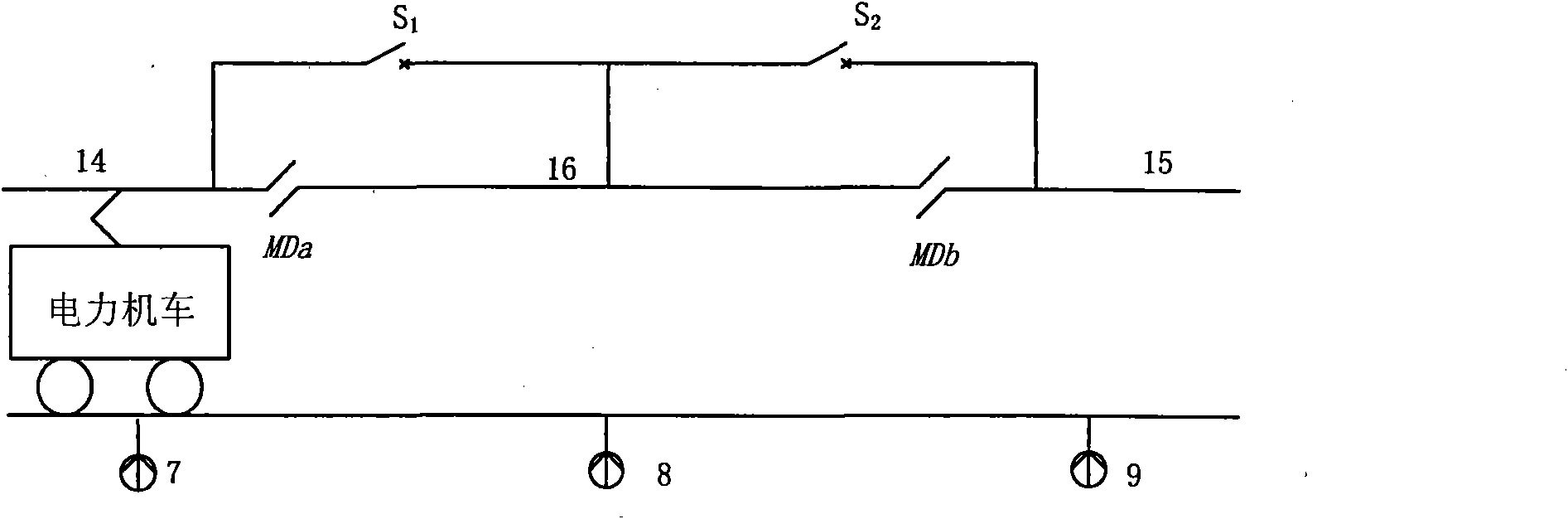

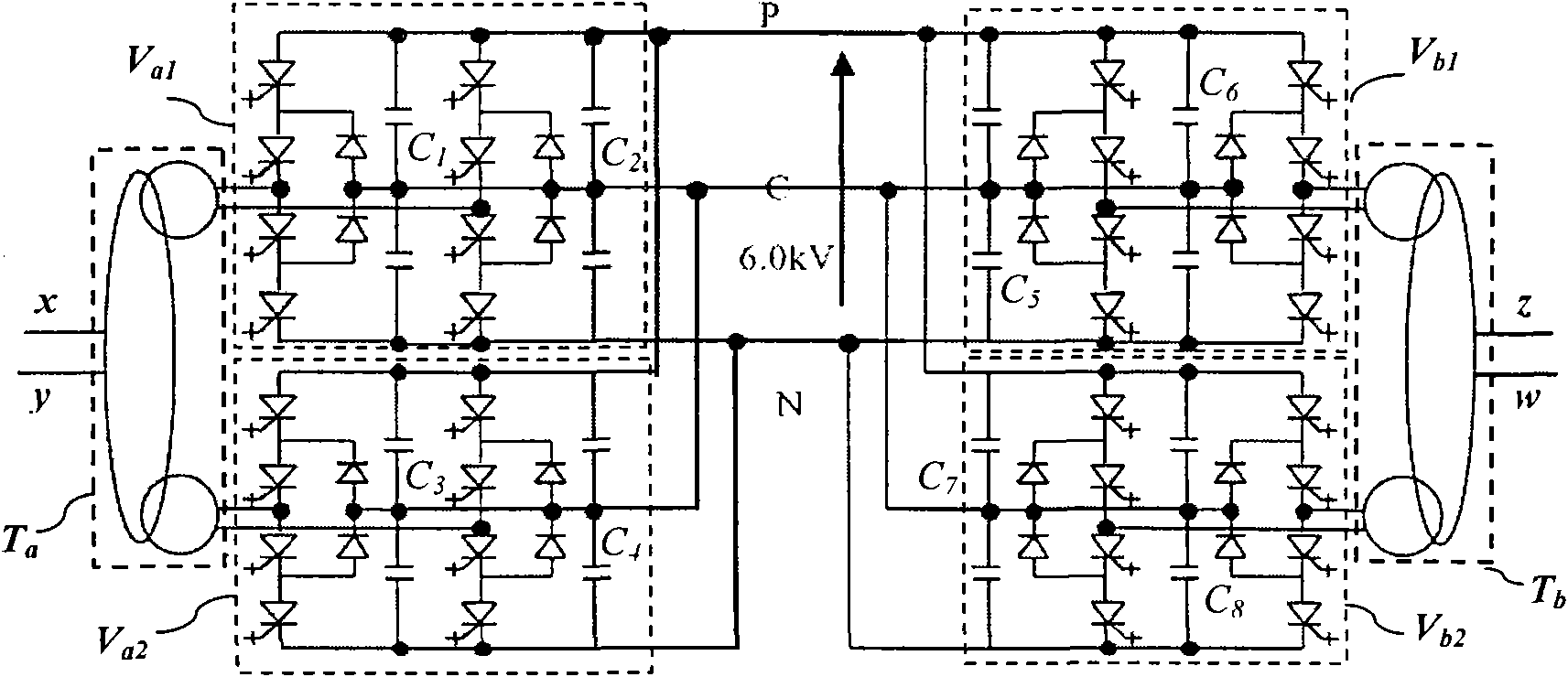

Embodiment 1

[0111] In Example 1, the converter group V a and V b The design rated power capacity is 10Mvar, and the 2-level H-bridge voltage source converter V composed of 3300V / 1400AIGBT is used. r , the average value of the DC side voltage can be about 2000V, the rated capacity of each H-bridge voltage source converter is 0.83Mvar, n=12. like Image 6 As shown, the two sides of the converter group V a and V b Each has 12 sets of capacitors, which are respectively connected through a common DC side to form 12 sets of mutually independent "back-to-back" converters. The series multiple transformer group T b Each series multiple transformer group consists of a total of 3 T r Composition, each multi-winding transformer T r The split connection method with 4 windings on the secondary side is selected, the voltage transformation ratio of the primary side / secondary side is 7.6:1 (9.2kV / 1.2kV), and each T r The rated power capacity of the transformer is selected as 3.3Mvar. The embodime...

Embodiment 2

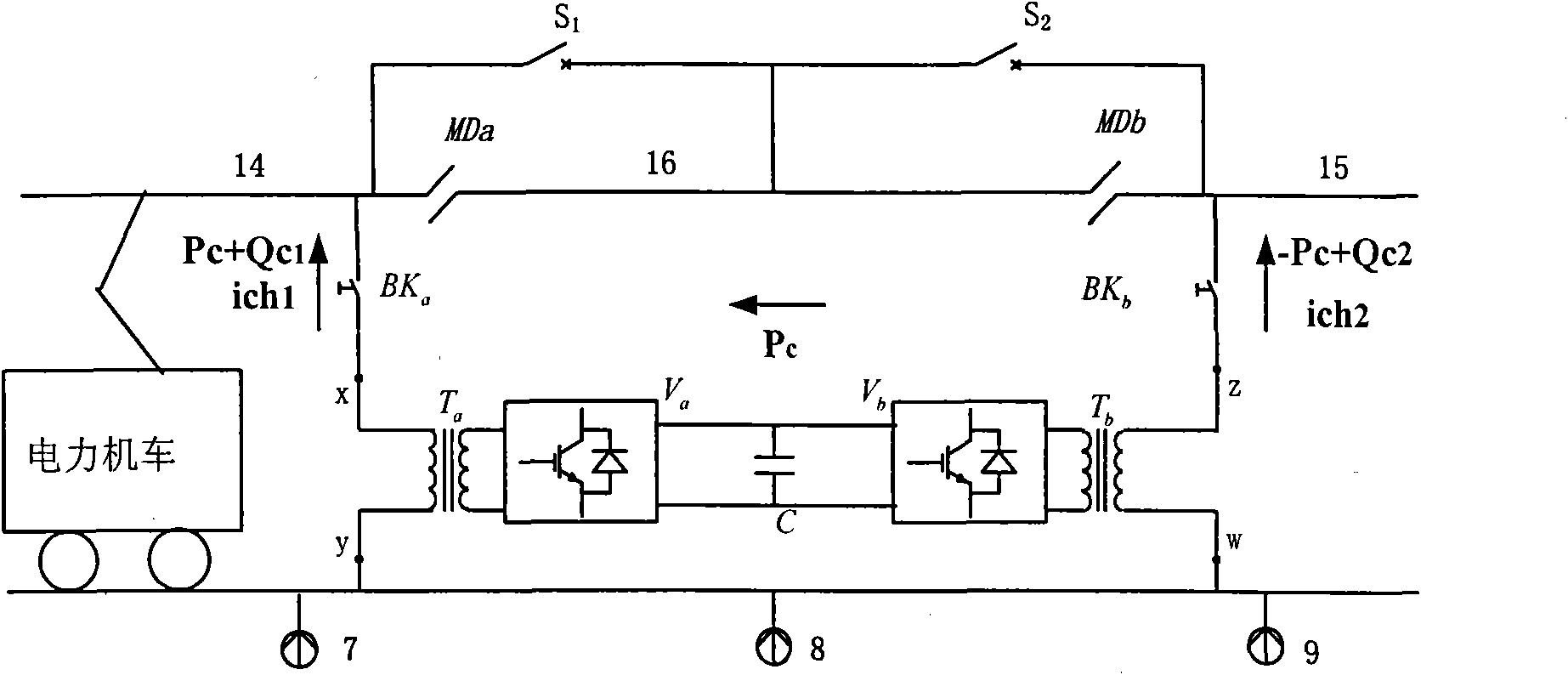

[0115] In Example 2, the converter group V a and V b The design rated power capacity is 14.2Mvar, and the 2-level H-bridge voltage source converter V composed of 3300V / 1000AIGBT is adopted. r , the average value of the DC side voltage can be about 2000V, the rated capacity of each H-bridge voltage source converter is 0.60Mvar, n=25. like Figure 7 As shown, the two sides of the converter group V a and V b Each has 25 sets of capacitors, which are respectively connected through a common DC side to form 25 sets of mutually independent "back-to-back" converters. Converter group V b The lead terminals z and w are directly connected to the traction power supply arm 15 . The embodiment selects the controllable switching switch 2 with a withstand voltage rating higher than 30kV, a rated current higher than 800A, and no on-load breaking capacity is required.

[0116] In Example 2, the power supply arm voltage V on both sides of the neutral section of the split phase α with V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com