Platinum-induced aurum core/ palladium platinum island-shaped alloy shell structure nanorod solution and preparation method

A technology of gold nanorods and nanorods, which is applied in the field of platinum-induced gold core/palladium-platinum island alloy shell structure nanorod solutions and preparation methods, can solve the problems of no improvement in catalytic performance, achieve improved catalytic performance, and increase transmission , the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

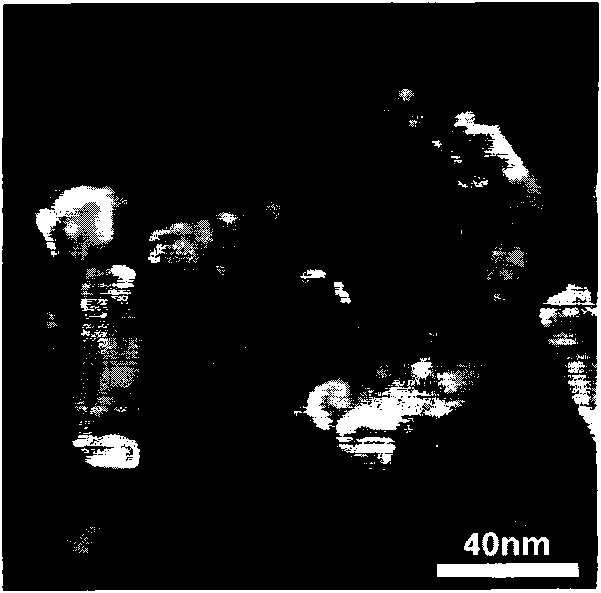

[0082] Put 1 mL of the gold nanorod solution obtained in the above step 2-(3) into a test tube, and add 40 μL of 2 mM potassium tetrachloroplatinite aqueous solution and 8 μL of 10 mM chloropalladium acid solution to the solution successively, mix well and then add 9.6 μL. .1M ascorbic acid aqueous solution and finally add deionized water to make up to 3mL; mix well and put it in a constant temperature water bath at 30°C. After 30 minutes, the solution turns from light red to gray red, indicating that the gold core / palladium platinum island alloy The formation of shell structure trimetallic nanorods; add 1mL 0.1M hexadecyltrimethylammonium bromide aqueous solution after 5~6 hours, to stabilize gold nucleus / palladium platinum island shape alloy shell structure trimetallic nanorods; The above reaction The solution was centrifuged at 12,000 rpm for 5 minutes; the supernatant was removed, the precipitate was diluted with deionized water to the original volume and ultrasonically dis...

Embodiment 2

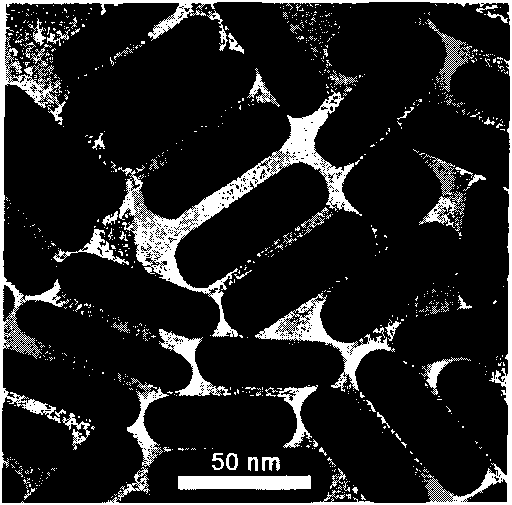

[0085] In this example, except that the volume of chloropalladium acid is selected as 20 μL, the remaining steps are the same as in Example 1, and the image of the porous trimetallic nanorod with the gold core / palladium-platinum alloy shell structure obtained is as follows: Figure 4b shown;

[0086] The mass ratio of chloropalladium acid, potassium tetrachloroplatinite and gold nanorods in the mixed solution in this example is 0.08:0.16:1.

Embodiment 3

[0088] In this example, except that the volume of chloropalladium acid is selected as 40 μL, the remaining steps are the same as in Example 1, and the image of the porous trimetallic nanorod with the gold core / palladium-platinum alloy shell structure obtained is as follows: Figure 4c shown;

[0089] The mass ratio of chloropalladium acid, potassium tetrachloroplatinite and gold nanorods in the mixed solution in this example is 0.16:0.16:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com