Formula and preparation method of granular pesticide

A granule and pesticide technology, which is applied in the formulation and preparation of phoxim granules, can solve the problems of short duration, heavy residue, high toxicity, etc., and achieve high drug adsorption rate, low manufacturing cost and long duration long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

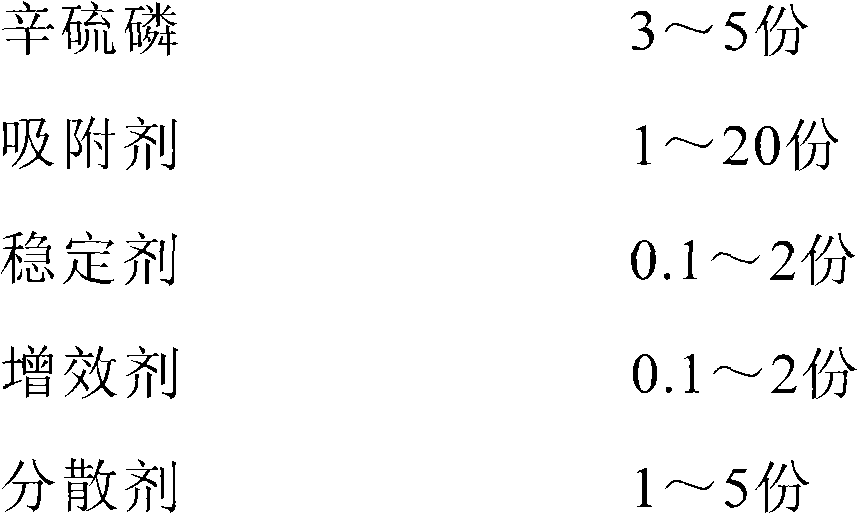

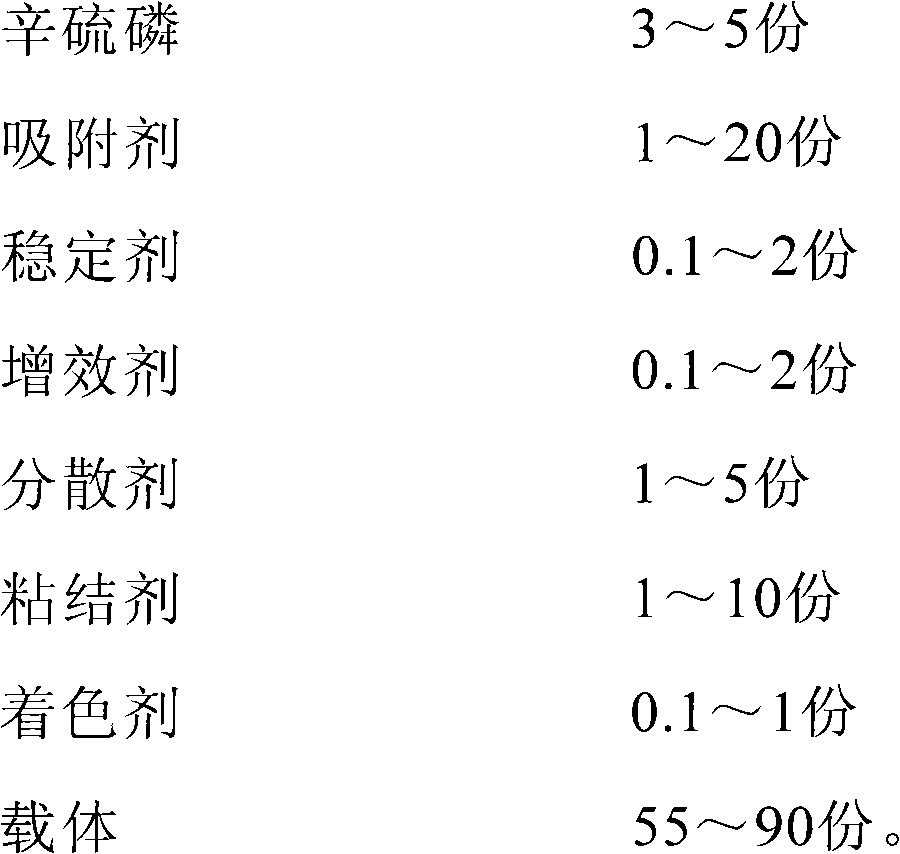

Method used

Image

Examples

Embodiment 1

[0016] Weigh 3.3 parts of phoxim original drug and add to 10 parts of white carbon black, mix evenly, set aside. Mix the above-mentioned mother powder with 80.5 parts of sieved attapulgite (about 20-40 mesh in particle size) and add them to the coating granulator for stirring, and add 10% polyvinyl alcohol aqueous solution gradually while stirring. 1 part, 0.5 part of organic silicon synergist, 2 parts of calcium lignosulfonate, 0.5 part of triphenyl phosphate and 0.2 part of acid red B, mix well and discharge, then dry and sieve to get 100 parts of qualified products .

Embodiment 2

[0018] Weigh 5 parts of emulsifiable concentrate preparation with high content of phoxim and add to 20 parts of calcium carbonate, mix evenly, set aside. Mix the above-mentioned mother powder with 55 parts of sieved attapulgite (with a particle size of about 20-40 mesh) and add them to a coating granulator for stirring, and add 10 parts of 10% starch aqueous solution gradually while stirring, 2 parts of methyl synergist, 5 parts of fatty alcohol polyoxyethylene ether, 2 parts of phosphorous acid and 1 part of acid scarlet, mixed well and discharged, dried and sieved to obtain 100 parts of qualified products.

Embodiment 3

[0020] Weigh 3 parts of phoxim original drug and add to 4.7 parts of diatomaceous earth, mix evenly, set aside. Mix the above-mentioned mother powder with 90 parts of sieved attapulgite (about 20-40 mesh in particle size) and add them to the coating granulator for stirring, and add 1 part of 10% dextrin solution gradually while stirring , 0.1 part of synergistic ether, 1 part of sodium dodecylbenzenesulfonate, 0.1 part of hydroxysulfonic acid and 0.1 part of pinnatine violet, mix well and discharge, dry and sieve to obtain 100 parts of qualified products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com