Lamellar ordered hybrid coating film and preparation method thereof

A hybrid and coating technology, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve problems such as the inability of polymer coating materials to meet requirements, and achieve the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

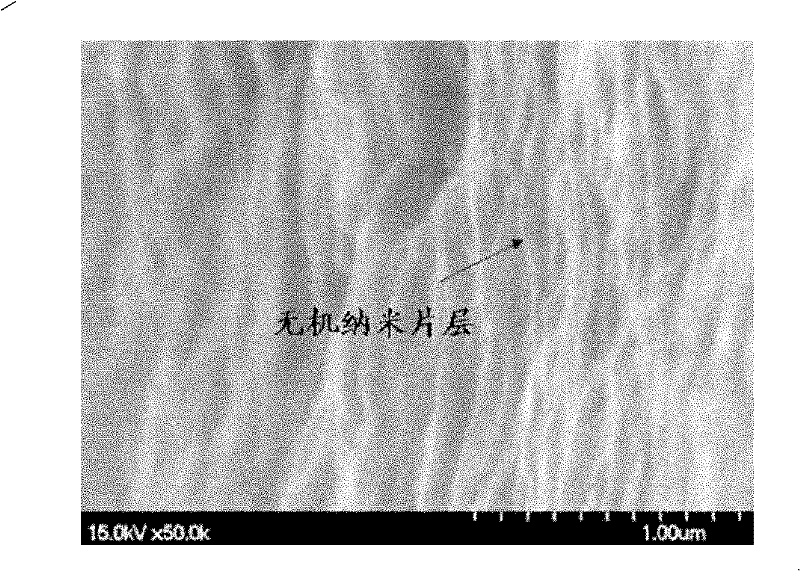

Image

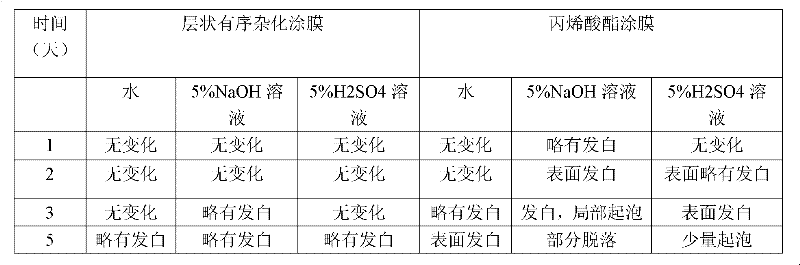

Examples

Embodiment 1

[0031] Add 0.1 g of montmorillonite (sodium-based montmorillonite, Zhejiang Linan Huate Clay Co., Ltd.) into 100 g of water, stir at room temperature for 1 hour, and then disperse for 10 minutes under an ultrasonic wave with a power of 100 W to obtain a suspension of montmorillonite.

[0032]Dissolve 1.0g of cetyltrimethylammonium chloride in 100g of deionized water, raise the temperature to 70°C, add 18g of styrene, 14g of methyl methacrylate, 38g of butyl acrylate mixed monomer, 0.1g of azo For diisobutylamidine hydrochloride (AIBA), keep the temperature for reaction for 5 hours, cool the system down to room temperature to obtain an acrylate emulsion, and the solid content is 40wt% by weighing method.

[0033] On the pretreated glass plate, the acrylate emulsion was spin-coated with a spin coater at 1500 rpm for 5 minutes to obtain a polymer layer of 250 nm (measured by AFM), dried for 3 minutes, and then coated on the polymer layer On top, the montmorillonite suspension was...

Embodiment 2

[0043] Add 1.0 g of montmorillonite (calcium-sodium-based montmorillonite, Zhejiang Lin'an Huate Clay Co., Ltd.) into 100 g of water, stir at room temperature for 1 h, and then disperse under 200 W ultrasonic waves for 10 minutes to obtain a suspension of montmorillonite.

[0044] Dissolve 1.0g of dodecyltrimethylammonium chloride in 100g of deionized water, raise the temperature to 70°C, add 18g of styrene, 14g of methyl methacrylate, 38g of butyl acrylate mixed monomer, 0.1g of azo For diisobutylamidine hydrochloride (AIBA), keep the temperature for reaction for 5 hours, cool the system down to room temperature to obtain an acrylate emulsion, and the solid content is 40wt% by weighing method.

[0045] On the pretreated glass plate, the acrylate emulsion was spin-coated with a spin coater at 500 rpm for 1 minute to obtain a polymer layer of 450 nm (measured by AFM), placed to dry for 5 minutes, and then coated on the polymer On the layer, the montmorillonite suspension is als...

Embodiment 3

[0047] Add 1.0 g of montmorillonite (sodium-based montmorillonite, Zhejiang Lin'an Huate Clay Co., Ltd.) into 100 g of water, stir at room temperature for 1 h, and then disperse for 10 minutes under the action of 200 W ultrasonic waves to obtain a suspension of montmorillonite.

[0048] Dissolve 3.0g of methacryloyloxyethyltrimethylammonium bromide in 100g of deionized water, raise the temperature to 80°C, add 3.0g of methyl methacrylate, 3.0g of acrylic acid, 4.0g of butyl acrylate mixed monomer, 0.3 g of azobisisobutylamidine hydrochloride (AIBA) was kept at the temperature for 8 hours, and the system was cooled to room temperature to obtain an acrylate emulsion, the solid content of which was 8.0 wt % by weighing method.

[0049] On the pretreated glass plate, the acrylate emulsion was spin-coated for 3 minutes by a spin coater with a speed of 1000 rpm to obtain a 50nm (AFM measurement) polymer layer, which was placed for 3 minutes, and then coated on the polymer layer Abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com