Adhesive composed of crosslinkable polyolefin and adhesive bonding resin

A pressure-sensitive adhesive, cross-linked polyolefin technology, applied in the direction of graft polymer adhesives, film/sheet adhesives, adhesive types, etc., can solve the problems of high cost, lining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

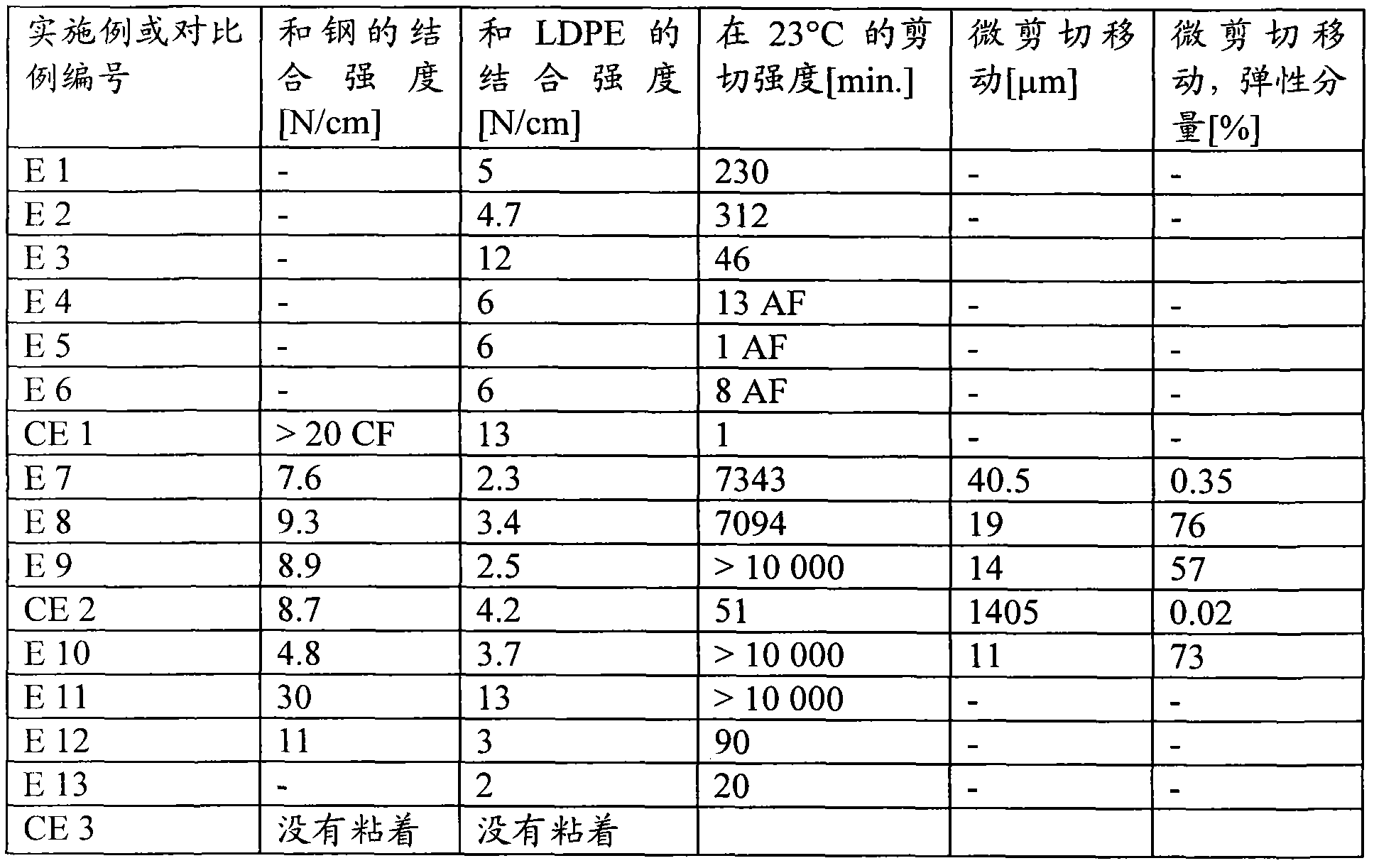

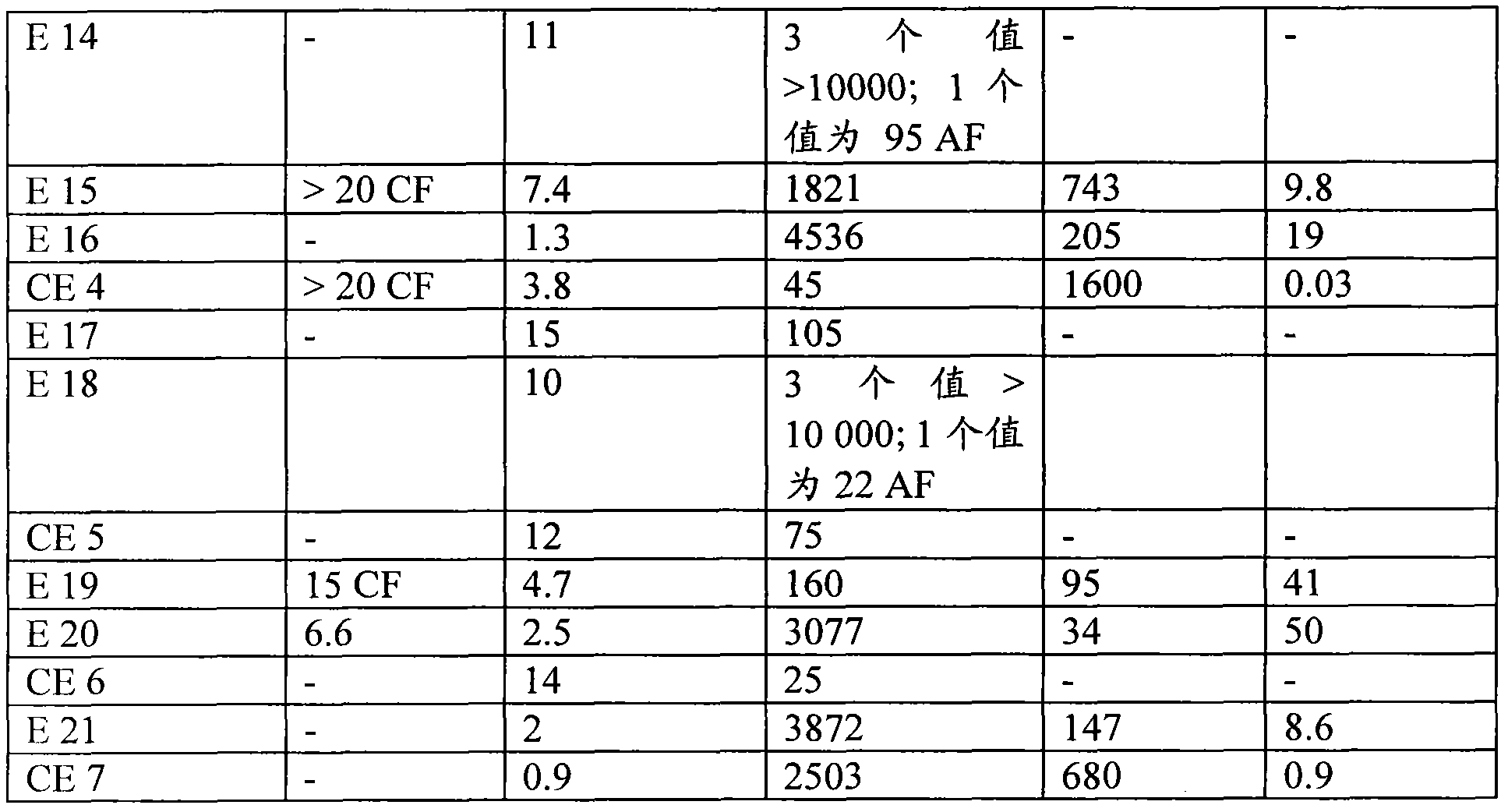

Examples

Embodiment 1

[0124] Tafmer A 0550S was grafted with 1 wt% maleic anhydride in the extruder. 25.5 parts by weight of the polymer, 54 parts by weight of Escorez 1310, 20 parts by weight of Ondina 933 and 0.5 parts by weight of Irganox 1726 were mixed in the melt, and the 2 Coat weights were coated on a 25 μm polyester film etched with trichloroacetic acid.

Embodiment 2

[0126] Carry out as Example 1, but also add 1 part by weight of Epicure 925 per 100 parts by weight of binder (polymer and additives).

Embodiment 3

[0128] Infuse 9817 was grafted with 1 wt% maleic anhydride in the extruder. Mix 25.5 parts by weight of the polymer, 50 parts by weight of Escorez 1310 and 27 parts by weight of Wingtack 10 in the melt, and use 250g / m 2 Coat weights were coated on a 25 μm polyester film etched with trichloroacetic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com