Method for measuring content of cyclohexanone-oxime by liquid chromatography

A cyclohexanone oxime and liquid chromatography technology is applied in the field of liquid chromatography for determining the content of cyclohexanone oxime in Beckmann rearrangement liquid in caprolactam production, and can solve the problems of complex analysis process, low recovery rate, high formaldehyde toxicity, etc. problems, to achieve the effect of simple analysis steps, high analysis accuracy and less harmful reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Determination of cyclohexanone oxime content in the reaction solution,

[0016] Because the caprolactam production unit by cyclohexanone oxime method has not been started yet, the amidation reaction product solution of caprolactam production by toluene method is added with cyclohexanone oxime standard reagent to prepare the tested sample solution, and the amidation reaction product solution is a mixture of caprolactam and concentrated sulfuric acid. The measurement steps are:

[0017] (1) Preparation of standard solution: Take 0.0925 g of cyclohexanone oxime chromatographically pure reagent, dissolve it in water, put it into a 100ml volumetric flask, and dilute to the mark with distilled water. Take 5ml from it, add 0.1M NaOH to make PH = 8-9, put it in a 100ml volumetric flask, dilute to the mark with distilled water, and it is A solution. Take 5ml from solution A and place it in a 100ml volumetric flask, dilute to the mark with distilled water, and obtain s...

Embodiment 2

[0023] Embodiment 2 repeatability test

[0024] Take 21.8894g of the amidation reaction liquid, add 0.0306g of cyclohexanone oxime, add ice water and 4M NaOH for hydrolysis and neutralization, weigh 185.57g in total, and have a pH value of 8-9 to prepare 10 samples. Using the standard solution and calibration solution in Example 1, a calibration curve was established according to the steps and instrument conditions in Example 1, and 10 samples were measured. The measurement results are shown in Table 1.

[0025] Table 1 Analysis results of repeatability test

[0026] sample

Embodiment 3

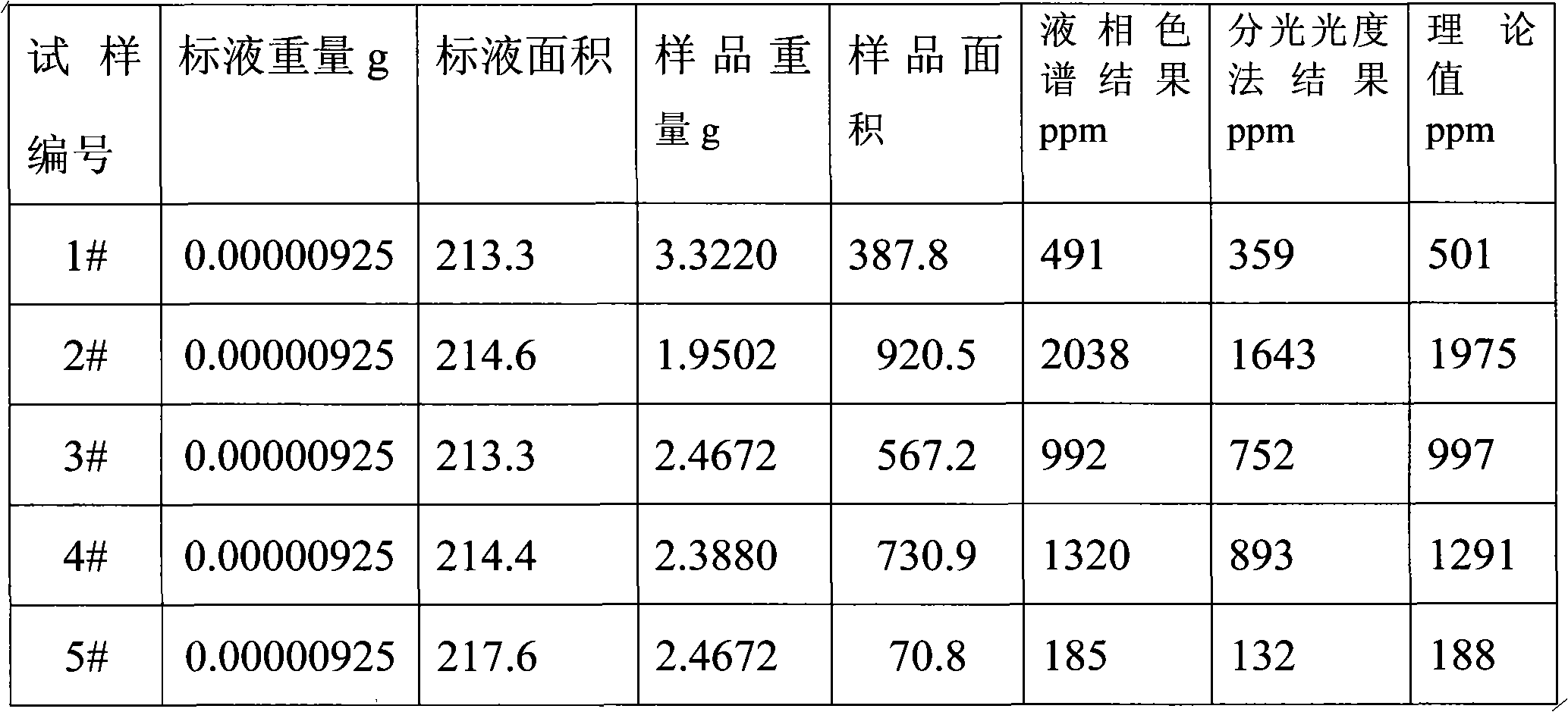

[0027] Embodiment 3 comparative test

[0028] In order to verify the accuracy of the determination of the present invention, the tested samples were prepared with caprolactam, cyclohexanone oxime and different amounts of 50% sulfuric acid. The composition of the prepared samples is shown in Table 2. Accurately weigh the samples in Table 2, hydrolyze with ice water, and neutralize with 4M NaoH to pH=8-9, dilute and make to volume in a 100ml volumetric flask. Using the standard solution and calibration solution in Example 1, establish a calibration curve according to the steps and instrument conditions in Example 1, and measure the sample and calculate the content of cyclohexanone oxime. As a comparison, the tested samples in Table 2 were measured by spectrophotometry at the same time, and the measurement results are shown in Table 3. The results show that the liquid chromatography method of the present invention has a much higher determination accuracy of the trace cyclohexano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com