Ammonia nitrogen removing device assisting organic compound denitrifier in treating high concentration ammonia nitrogen wastewater

The technology of compound denitrification agent and ammonia nitrogen wastewater is applied in the field of high-concentration ammonia nitrogen wastewater treatment device, which can solve the problems of increasing investment cost and operating cost, consuming large chemicals and energy, and unable to remove ammonia nitrogen, etc., so as to increase gas-liquid mass transfer. Efficiency, reduced operating cost and power consumption, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

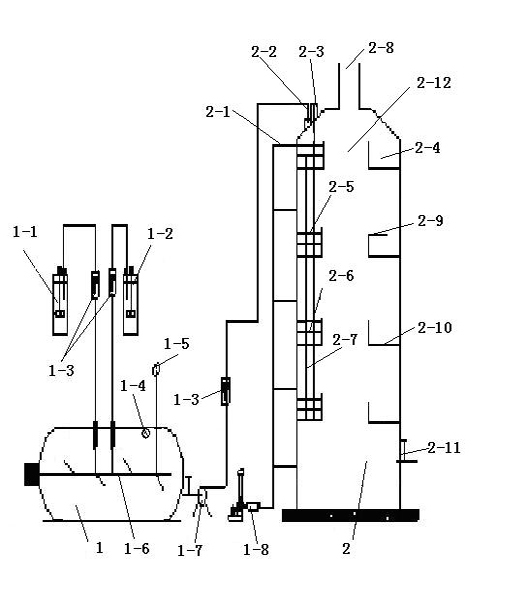

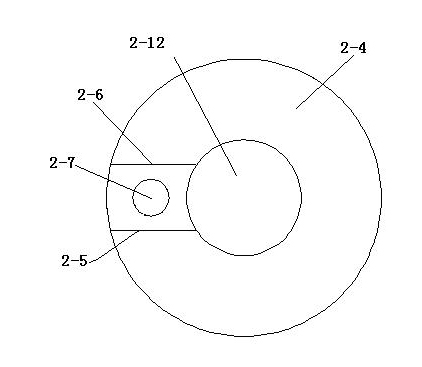

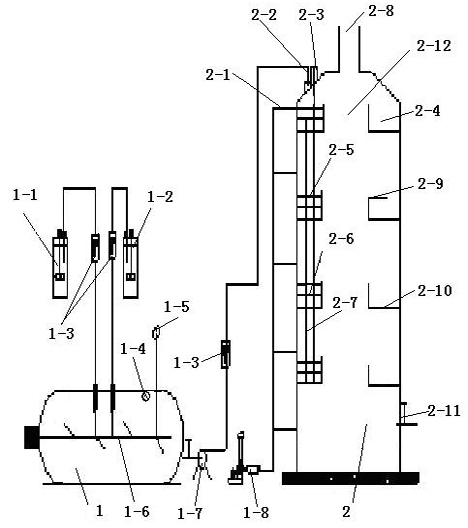

[0011] Such as figure 1 , the present invention includes a reaction pool 1 and a denitrification tower 2, and the reaction pool 1 and the denitrification tower 2 communicate with each other through pipelines. There are two chemical pools on the top of the reaction pool 1, the first chemical pool 1-1 and the second chemical pool 1-2 are connected to the reaction pool 1 through pipelines respectively, and each of the pipelines between the two chemical pools and the reaction pool 1 Install a liquid flow meter 1-3. A mixing and stirring device 1-6 is arranged in the inner cavity of the reaction pool 1 to stir the liquid in the reaction pool 1. An opening 1-4 is opened on the upper wall of the reaction pool 1, and the opening 1-4 communicates with the ventilation duct 2-8 at the upper mouth of the denitrification tower 2 through a pipeline. The reaction pool 1 is externally connected with a pH meter 1-5, so that the pH meter 1-5 extends into the reaction pool 1, and the pH value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com