Manufacturing process of photonic crystal fiber

A technology of photonic crystal fiber and manufacturing process, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass fiber products, etc., can solve the problems of different manufacturing technologies of photonic crystal fiber, and there is no detailed report of photonic crystal fiber technology, so as to avoid additional impurities Introduction, fiber loss reduction, low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

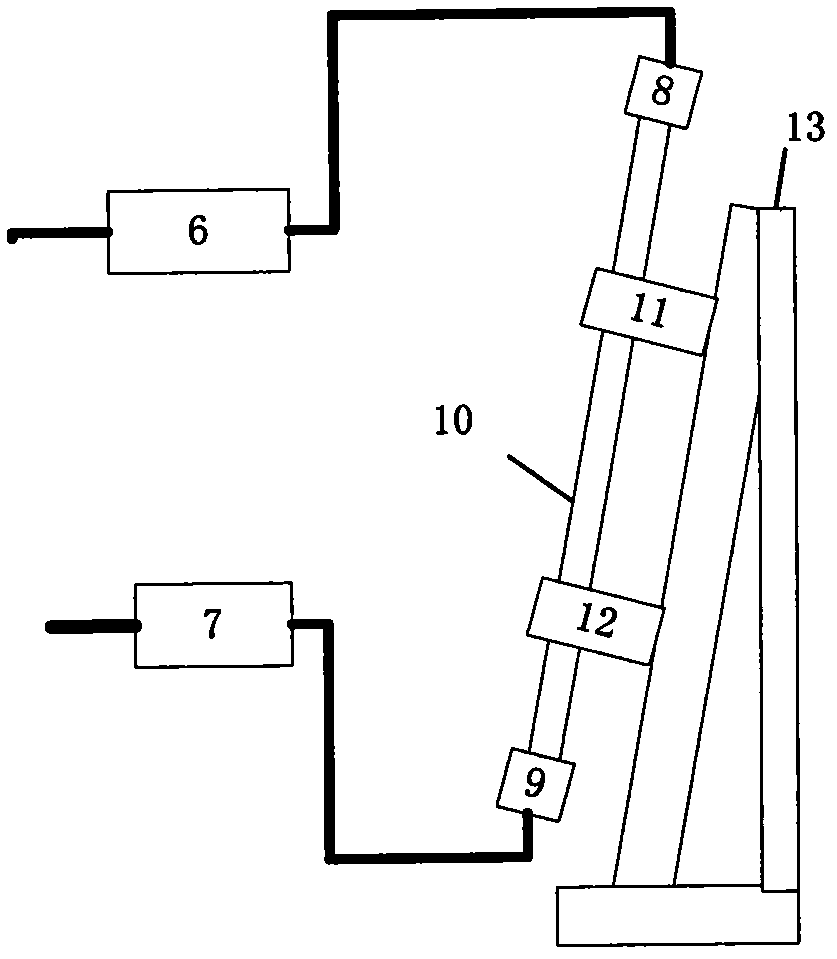

[0064] For the preparation of photonic crystal fiber, whether it is total internal reflection photonic crystal fiber or hollow bandgap photonic crystal fiber, in order to reduce the loss of the fiber, it is also necessary to reduce the impurity content and increase the fiber axial And radial uniformity, in order to prepare low-loss photonic crystal fiber.

[0065] In addition, if the photonic crystal fiber is drawn by the beamforming method, it is necessary to study the capillary dynamics and micropore characteristics of the photonic crystal fiber. The size, shape and deviation of microholes arranged in the cross-section of photonic crystal fiber have a great influence on various functional parameters of the fiber (such as zero dispersion point, nonlinearity, and single-mode transmission bandwidth).

[0066] Under the high temperature condition of about 2000 ℃, the molten glass has a certain viscosity, and the temperature rises, and the viscosity of the quartz glass melt decre...

Embodiment 1

[0109] A quartz glass tube with an outer diameter of 40mm, a wall thickness of 1.5mm, and a length of 2000mm is used as the substrate tube, and nearly a thousand layers of high-purity quartz material are deposited on the inner wall of the quartz glass tube by using an optical fiber preform deposition lathe, so that the pure quartz material wall about 1 mm thick,

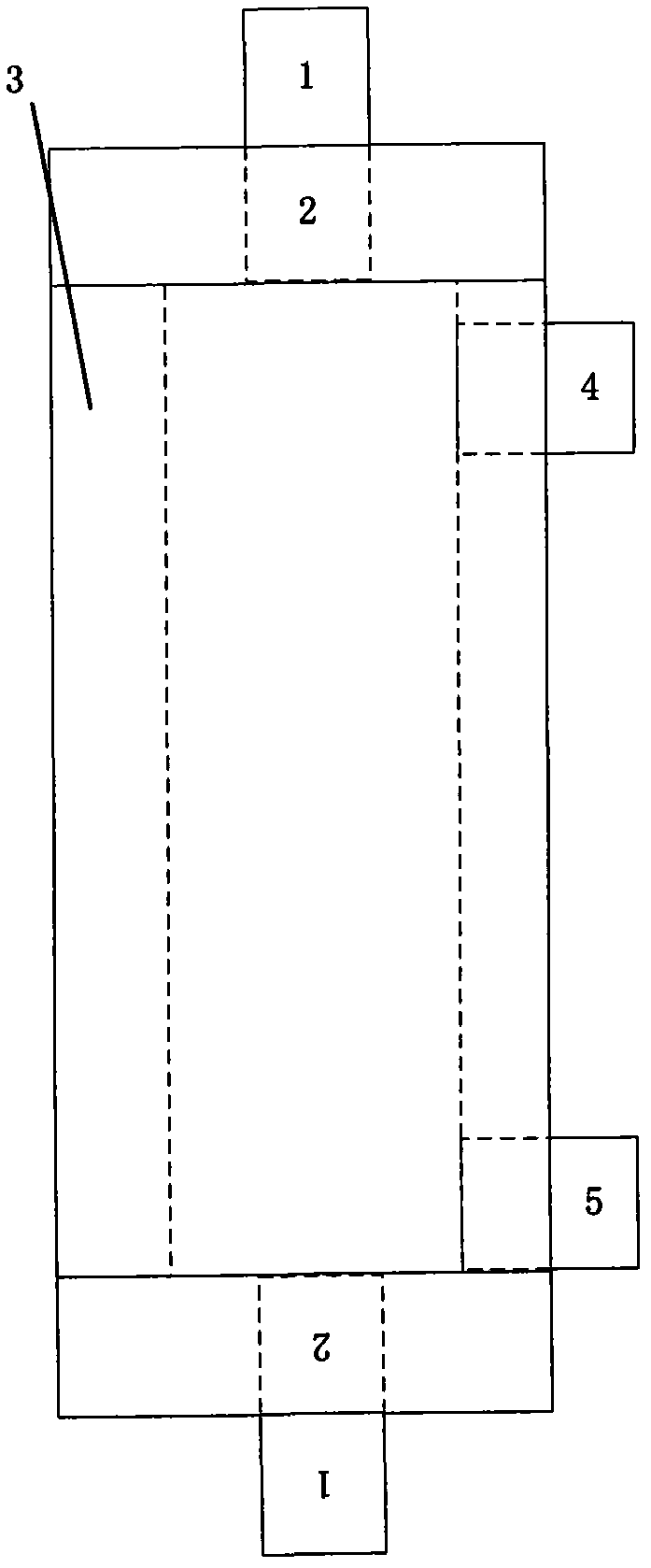

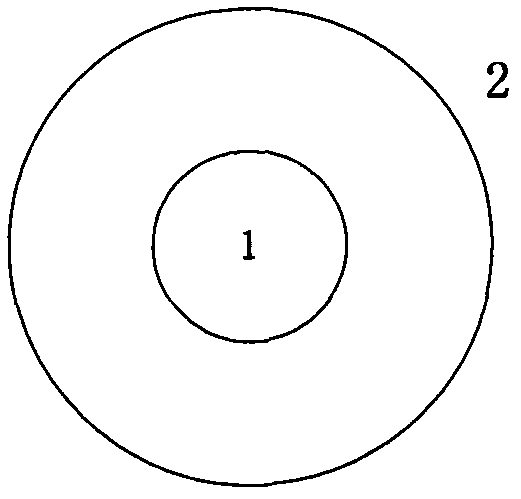

[0110] Put the quartz glass tube in figure 1 and figure 2 In the shown substrate tube erosion device, the substrate tube is locked by a circular ferrule 1 and a flange 2, so that the substrate tube is in the center of the substrate tube erosion device. Then inject strong acid through the upper inlet 4, and the lower inlet 5 is closed. After a period of time, the strong acid is exported from the lower inlet 5, and then the substrate tube erosion device is inverted, and the strong acid is injected from the lower inlet 5. After a period of time, After the original substrate tube material is completely eroded, the str...

Embodiment 2

[0118] A quartz glass tube with an outer diameter of 35mm, a wall thickness of 2.5mm, and a length of 1600mm is used as the substrate tube, and the optical fiber preform deposition lathe is used to deposit thousands of layers of high-purity quartz materials doped with germanium and fluorine on the inner wall of the quartz glass tube. The deposition thickness reaches 3mm,

[0119] Put the quartz glass tube in figure 1 and figure 2 In the shown substrate tube erosion device, the substrate tube is locked by a circular ferrule 1 and a flange 2, so that the substrate tube is in the center of the substrate tube erosion device. Then inject strong acid through the upper inlet 4, and the lower inlet 5 is closed. After a period of time, the strong acid is exported from the lower inlet 5, and then the substrate tube erosion device is inverted, and the strong acid is injected from the lower inlet 5. After a period of time, After the original substrate tube material is completely eroded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com