Method for preparing waterborne resin, and waterborne coating composition

A technology of water-based resin and water-based paint, applied in the field of paint, can solve the problem that water-based paint can not meet the anti-corrosion, chemical resistance, solvent resistance and other properties at the same time, and achieve the effect of excellent anti-corrosion, excellent weather resistance and harm reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

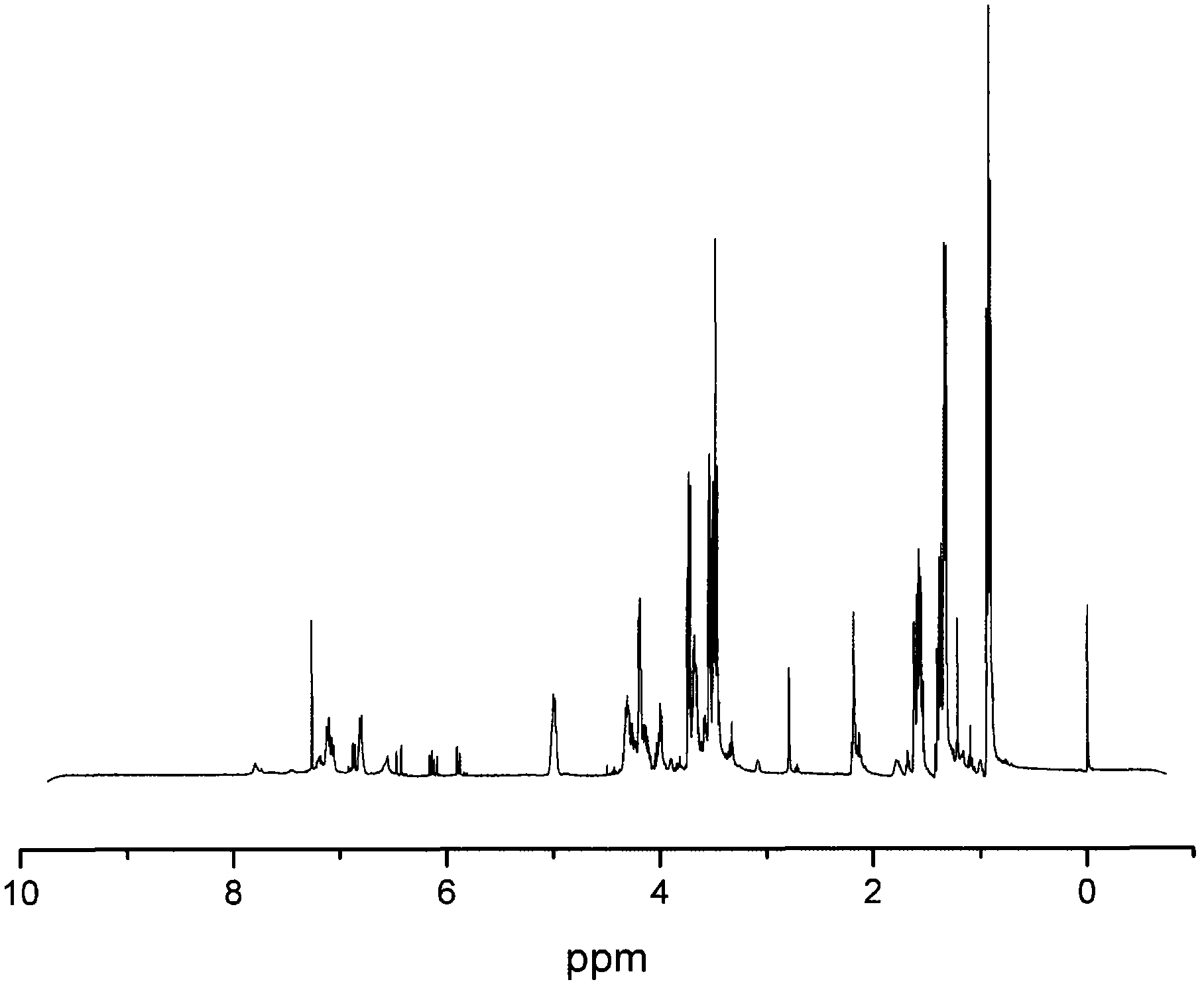

Image

Examples

preparation example Construction

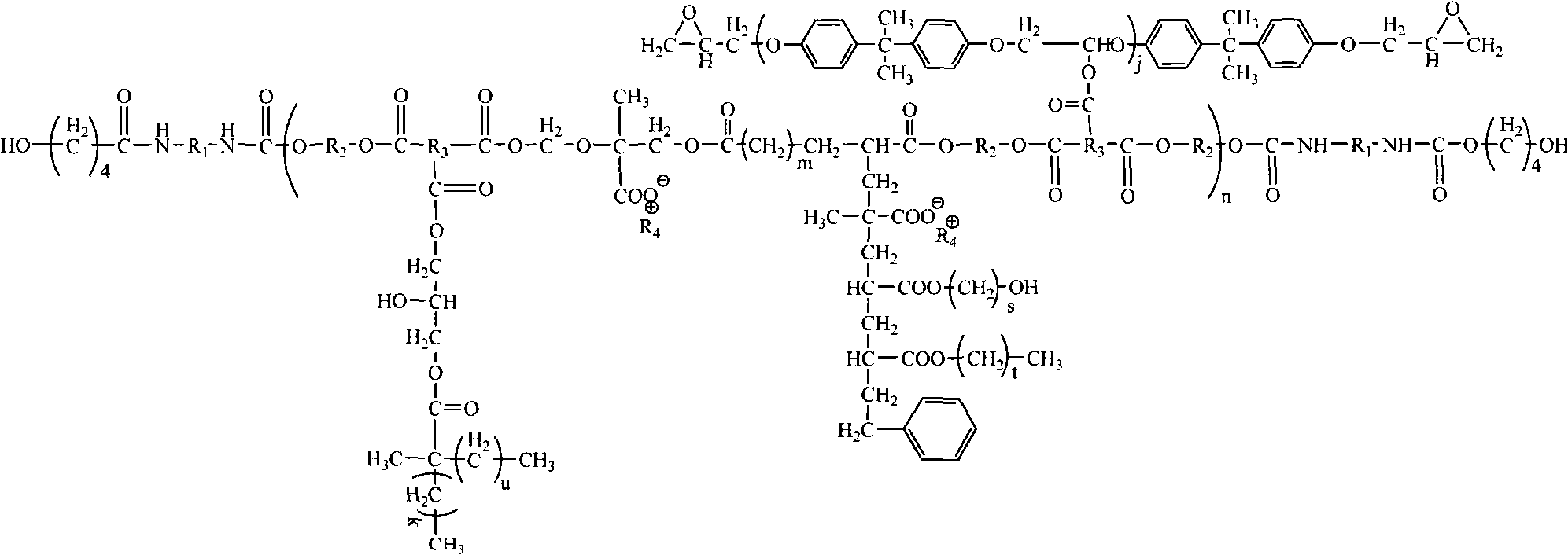

[0030] The invention discloses a preparation method of water-based resin, comprising the following steps:

[0031] Step a) Under nitrogen protection, 342-500 parts by weight of alkene diacid, 167-270 parts by weight of tricarboxylic acid, 74-146 parts by weight of dihydric alcohol, 375-431 parts by weight of dimethylol propionic acid, 78- 138 parts by weight of glycidyl tertiary carbonic acid ester, 90-250 parts by weight of epoxy resin, 10-30 parts by weight of antioxidant and 30-50 parts by weight of catalyst are heated to 130-215 °C for reaction, adding an aqueous solvent to obtain the first product;

[0032] Step b) under the protection of nitrogen, add 815-1100 parts by weight of reactive monomers, 6.9-9.2 parts by weight of free radical initiators and 8-15 parts by weight of chain transfer agents to the first product, and carry out free-radical polymerization to obtain The second product, the reactive monomers are methacrylic acid, styrene, hydroxy acrylate and acrylate...

Embodiment 1

[0054] Preparation of water-based resin P1:

[0055] According to the formula quantity shown in table 1, prepare according to the following method:

[0056] Step a) Under nitrogen protection, add glutaconedic acid, 2-phosphinobutane-1,2,4-tricarboxylic acid, 1,8-octanedioic acid to the device equipped with water separator, thermometer and condenser Diol, dimethylolpropionic acid, glycidyl ester E10P, epoxy resin E51, heated up to 170°C, reacted for 2 hours, then raised the temperature to 210°C at a heating rate of 10°C / 20min, continued to react for 3 hours, then Cool down to 130°C, add an aqueous solvent to obtain the first product;

[0057] Step b) Under nitrogen protection, add methacrylic acid, hydroxyethyl acrylate, butyl acrylate, and styrene to the first product, raise the temperature to 110°C, add the initiator benzoyl peroxide in 3 batches, and continue the reaction for 4 hours , adding the chain transfer agent dodecyl mercaptan, and reacting at 120°C for 1 hour to o...

Embodiment 2~5

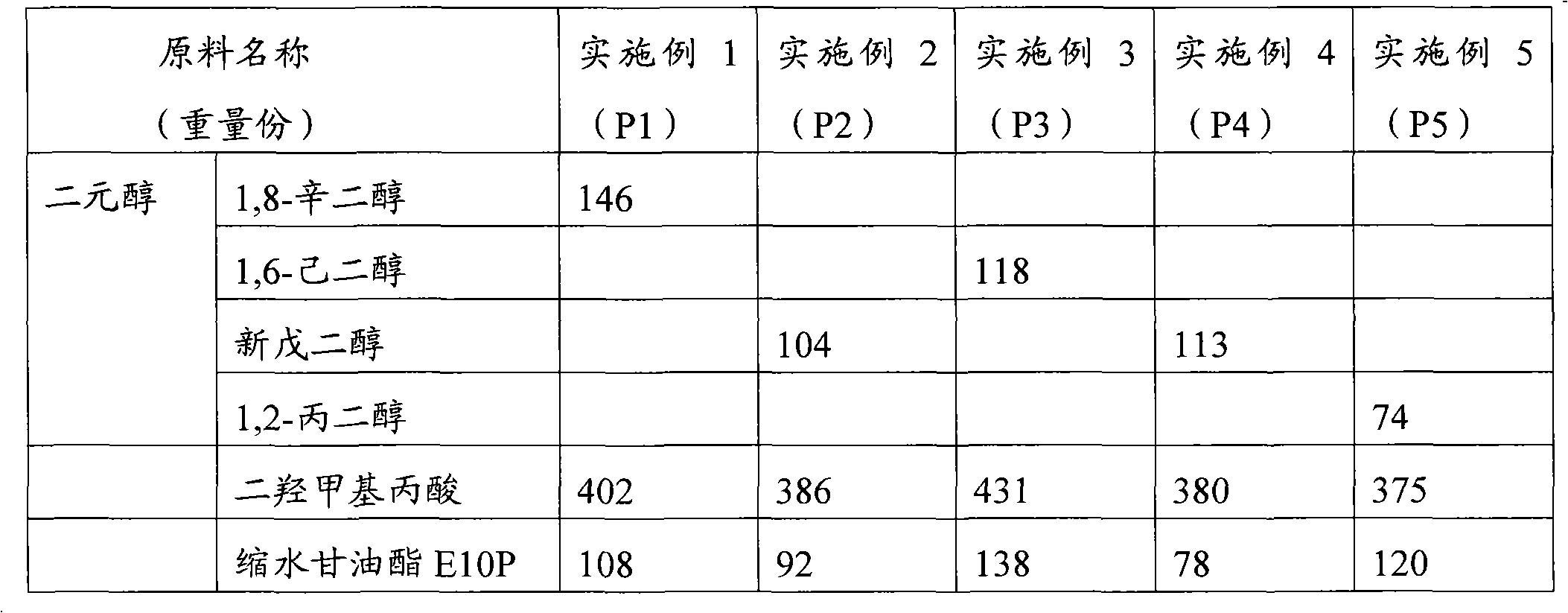

[0064] The preparation process of water-based resins P2-P5 is the same as in Example 1, and the specific process parameters are shown in Table 1.

[0065] Table 1 The raw material formula of the water-based resin prepared in Examples 1-5

[0066]

[0067]

[0068]

[0069] Table 2 Group structures in Examples 1 to 5

[0070]

[0071] n

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com