Preparation method of interpenetrating network formed phase-change material

A technology of interpenetrating network and phase change materials, which is applied in the field of aliphatic polymer compounds and its preparation, can solve the problem of no shape-fixed phase change materials for temperature-regulating fibers and fabrics, loss of phase change heat storage capacity of thermosetting polymers, and exchange It is difficult to control the joint density and other problems, and achieve the effect of excellent setting effect, good strength and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Accurately weigh 4g of network monomer N-methylolacrylamide (NHMPA), 0.6g of cross-linking agent N,N-methylene bisacrylamide (BIS), 18.9g of phase change material polyethylene glycol (PEG2000), Add 24ml of distilled water into a flat-bottomed flask, and after dissolving, ultrasonically disperse for 5 minutes, then add initiator ammonium persulfate (APS) 0.12g, and continue ultrasonically dispersing for 5 minutes, so that the large and small molecules in the solution are mixed evenly. React at 75°C for 3 hours to generate a synchronous interpenetrating network hydrogel. The prepared gel was put into an electric heating constant temperature blast drying oven and dried to a constant weight to obtain an interpenetrating network shape-setting phase change material.

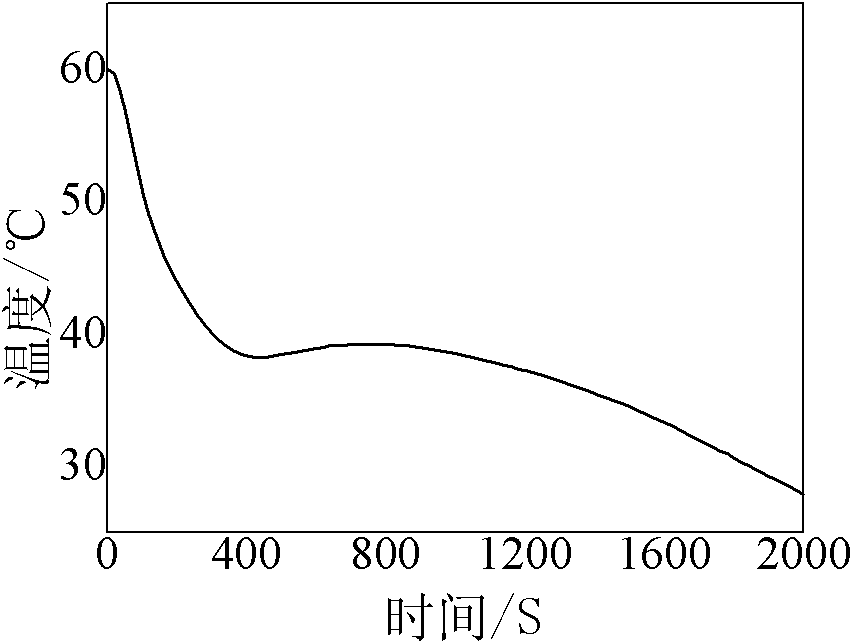

[0030] The prepared interpenetrating network shape-setting phase change material is tested for thermal insulation, and passed through the step cooling curve (see figure 1 ) analysis shows that the phase change ...

Embodiment 2

[0035] Accurately weigh 4g of network monomer N-methylolacrylamide (NHMPA), 0.8g of cross-linking agent N,N-methylene bisacrylamide (BIS), 11.3g of phase change material polyethylene glycol (PEG2000), Add 24ml of distilled water into a flat-bottomed flask, and after dissolving, ultrasonically disperse for 5 minutes, then add 0.1g of initiator ammonium persulfate (APS), and continue ultrasonically dispersing for 5 minutes, so that the large and small molecules in the solution are evenly mixed. The reaction was carried out at 75°C for 3 hours to generate a synchronous interpenetrating network polymer. The prepared polymer is put into an electric heating constant temperature blast drying oven and dried to a constant weight to obtain an interpenetrating network shape-setting phase change material.

Embodiment 3

[0037] Accurately weigh 4g of the network monomer N-methylolacrylamide (NHMPA), 0.6g of the cross-linking agent N,N-methylene bisacrylamide (BIS), 18.5g of the phase change material polyethylene glycol (PEG4000), Add 40ml of distilled water into a flat-bottomed flask, and after dissolving, ultrasonically disperse for 5 minutes, then add 0.08g of initiator ammonium persulfate (APS), and continue ultrasonically dispersing for 5 minutes, so that the large and small molecules in the solution are evenly mixed. React at 80°C for 3.5 hours to generate a synchronous interpenetrating network hydrogel. The prepared gel was put into an electric heating constant temperature blast drying oven and dried to a constant weight to obtain an interpenetrating network shape-setting phase change material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com