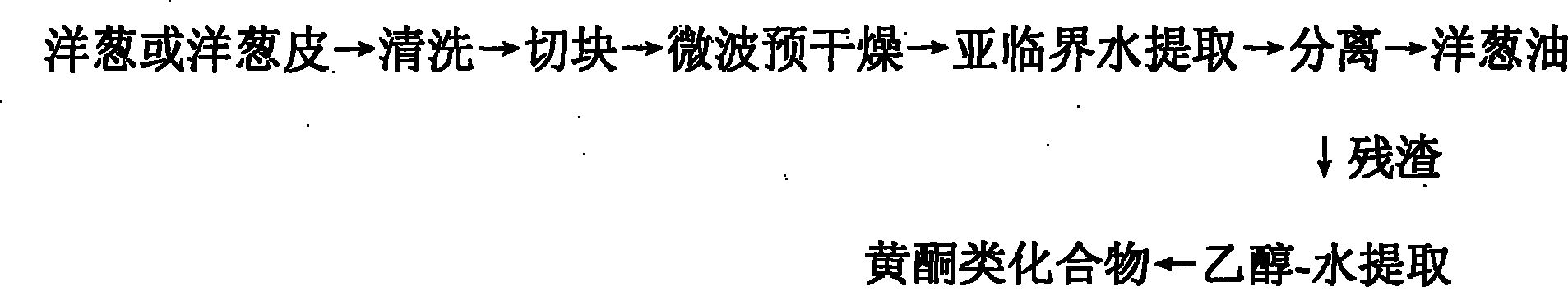

Method for preparing onion functional components by using double-stage extraction based on subcritical water and solvent method

A technology of subcritical water and functional ingredients, which is applied in the field of deep food processing, can solve the problems of difficult factory production, excessive damage to active ingredients, and incomplete extraction, so as to improve comprehensive utilization, shorten drying time, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 500g of onion, wash and cut into pieces, carry out microwave pre-drying under the conditions of microwave frequency 915MHz, power 300W, time 30min, transfer the above-mentioned onion pieces into a closed extraction kettle, use deoxygenated deionized water as solvent, and use 20% The ethanol was used as entrainer for subcritical water extraction of onion oil. Wherein, the extraction pressure is 5MPa, the extraction temperature is 150°C, and the extraction time is 30min. The above-mentioned extraction mixture is separated by cooling the tank under reduced pressure to obtain onion oil with higher purity. The extraction residue is subjected to ethanol-water extraction of the flavonoids, wherein the extraction temperature is 50° C., the ethanol concentration is 30%, the solid-liquid ratio is 1:25, and the extraction time is 100 min, to obtain the flavonoids.

Embodiment 2

[0021] Weigh 500g of onion skin, wash and cut into pieces, and carry out microwave pre-drying under the conditions of microwave frequency 915MHz, power 400W, and time 25min. % ethanol as entrainer for subcritical water extraction of onion oil. Wherein, the extraction pressure is 3MPa, the extraction temperature is 130°C, and the extraction time is 40min. The above-mentioned extraction mixture is separated by cooling the tank under reduced pressure to obtain onion oil with higher purity. The extraction residue is subjected to ethanol-water extraction of flavonoids, wherein the extraction temperature is 65° C., the ethanol concentration is 40%, the ratio of solid to liquid is 1:25, and the extraction time is 80 minutes to obtain flavonoids.

Embodiment 3

[0023] Weigh 500g of onion skin, after cleaning and cutting into pieces, carry out microwave pre-drying under the conditions of microwave frequency 915MHz, power 500W, and time 20min, transfer the above-mentioned onion pieces into a closed extraction kettle, use deoxidized deionized water as solvent, and use 30 % ethanol as entrainer for subcritical water extraction of onion oil. Wherein, the extraction pressure is 2MPa, the extraction temperature is 115°C, and the extraction time is 60min. The above-mentioned extraction mixture is separated by cooling the tank under reduced pressure to obtain onion oil with higher purity. The extraction residue is subjected to ethanol-water extraction of the flavonoids, wherein the extraction temperature is 80° C., the ethanol concentration is 50%, the solid-liquid ratio is 1:25, and the extraction time is 60 minutes, to obtain the flavonoids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com